A kind of melting method of zirconium-based amorphous alloy master alloy

A zirconium-based amorphous alloy and master alloy technology, applied in the field of amorphous alloys, can solve the problems affecting the forming properties of the zirconium-based amorphous alloy master alloy, the large volume of zirconium, and the failure to exclude zirconium impurities, etc., to achieve low oxygen and nitrogen content, The effect of uniform composition and elimination of harmful impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

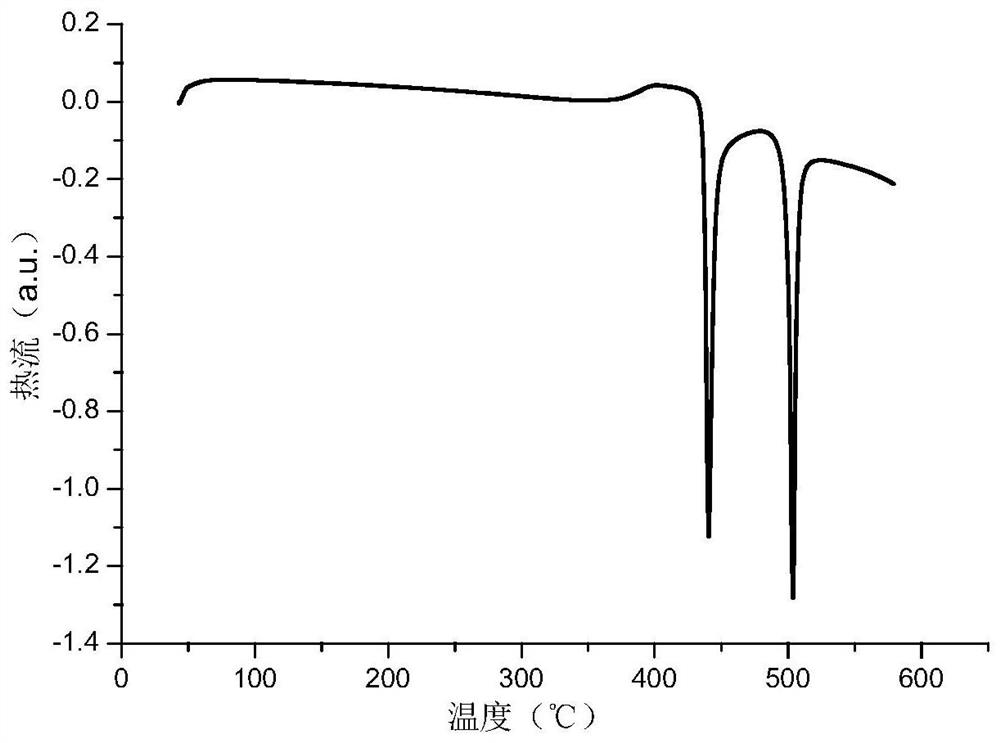

Image

Examples

Embodiment 1

[0029] In this embodiment, the brand name of the amorphous alloy is: AEM-1, the melting method of zirconium-based amorphous alloy master alloy, which includes:

[0030] (1) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0031] (2) Install the crucible in the inductor, bake and evacuate, heat through coil induction, load the power to 10kW to preheat the crucible, keep it warm for 6 hours, and the preheating temperature is 500°C;

[0032] (3) Add a zirconium electrode into the crucible, fill it with protective gas, load the power to 70kW, heat and melt through the coil induction, adjust the power in time according to the state of the molten pool, and control the heating temperature to 1600°C;

[0033] (4) After melting for 15 minutes, open the secondary feeding device, add niobium, copper, nickel, aluminum and yttrium into the crucible, continue heating until the melting is uniform, pour into a water-cooled mold, and cool to obtain a zirconium-ba...

Embodiment 2

[0036] In this embodiment, the brand name of the amorphous alloy is: AEM-1, the melting method of zirconium-based amorphous alloy master alloy, which includes:

[0037] (1) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0038] (2) Install the crucible in the inductor, bake and evacuate, heat through the coil induction, load the power to 20kW to preheat the crucible; preheat the crucible, keep it warm for 8 hours, and the preheating temperature is 1200 ℃;

[0039] (3) Add a zirconium electrode into the crucible, fill it with protective gas, load the power to 30kW, heat and melt through coil induction, adjust the power in time according to the state of the molten pool, and control the heating temperature to 1000°C;

[0040] (4) After melting for 30 minutes, open the secondary feeding device, add copper and aluminum to the crucible, continue heating until the melting is uniform, pour into a water-cooled mold, and cool to obtain a zirconium-based ...

Embodiment 3

[0043] In this embodiment, the brand name of the amorphous alloy is: AEM-1, the melting method of zirconium-based amorphous alloy master alloy, which includes:

[0044] (1) mechanically compacting the zirconium sponge to obtain a zirconium electrode;

[0045] (2) Install the crucible, start the equipment, load the power, bake the crucible under atmospheric environment and vacuum conditions respectively, heat and vacuumize, keep warm for 4 hours, and the preheating temperature is 800°C;

[0046] (3) Add a zirconium electrode to the crucible, fill it with protective gas, load the power to 50kW, heat and melt through coil induction, adjust the power in time according to the state of the molten pool, and control the heating temperature to 1200°C;

[0047] (4) After 20 minutes of melting, open the secondary feeding device, add aluminum and niobium into the crucible, continue heating until the melting is uniform, pour into a water-cooled mold, and cool to obtain a zirconium-based am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com