A kind of preparation method of Fe, Al, Co, Cu, Cr, Mn alloy target material

An alloy target and alloy technology, which is applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of poor machining and forming performance, poor bonding force between raw materials, and low target density. Achieve the effect of eliminating precious metal loss, improving density and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

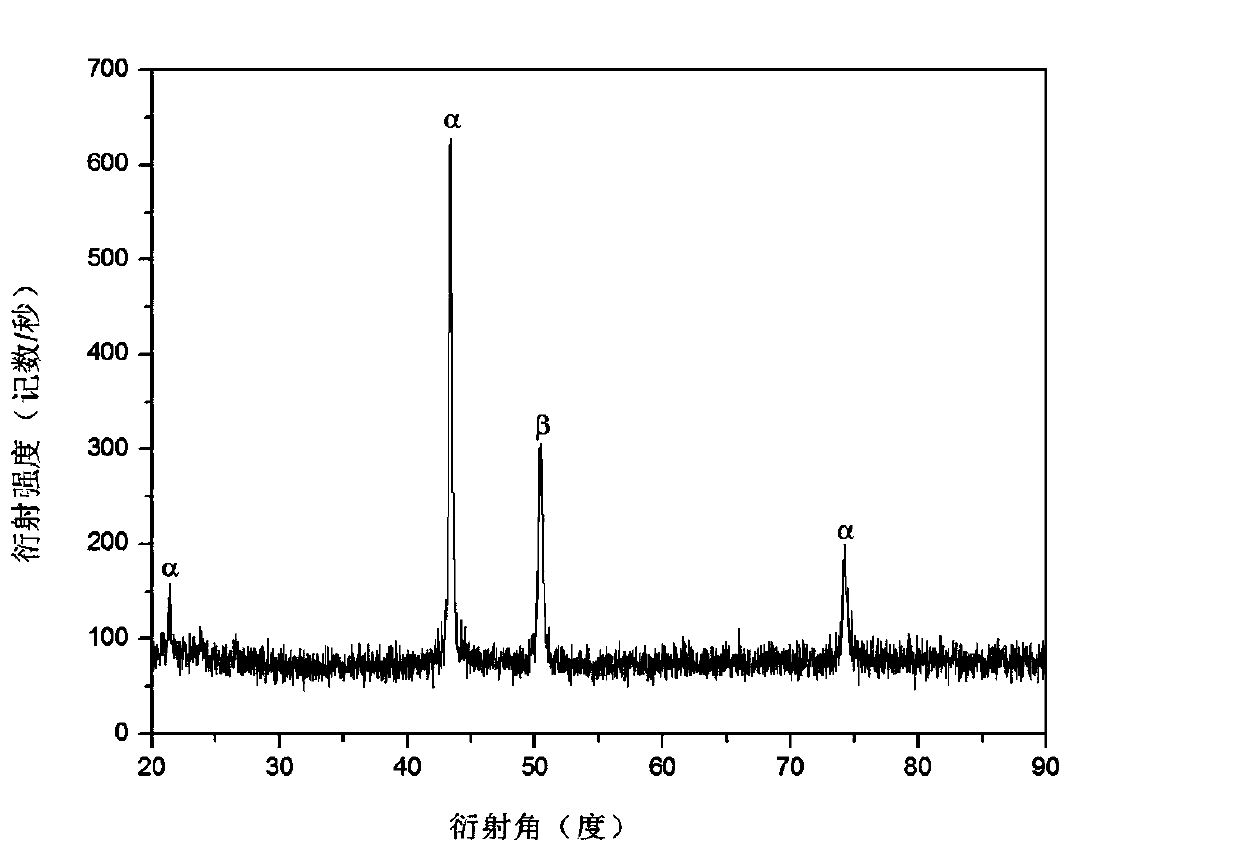

[0029] Embodiment 1. This embodiment describes a method for preparing Fe, Al, Co, Cu, Cr, Mn alloy targets, and the preparation method includes the following process:

[0030] (1) Selection and proportioning of raw materials: select Fe, Al, Co, Cu, Cr, Mn bulk metals with a purity greater than 99.9% respectively, and mix them according to the ratio of atomic equimolar ratios to obtain alloy raw materials with equimolar ratios Element;

[0031] (2) Alloy smelting: In a non-consumable vacuum smelting furnace, the mixed alloy raw materials are smelted to obtain alloy ingots;

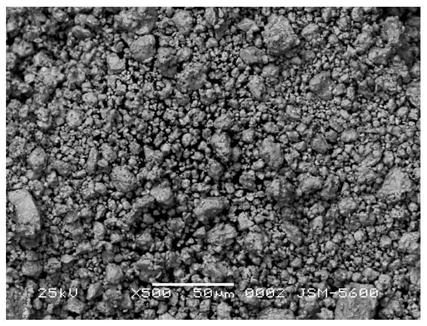

[0032] (3) Powdering of alloy ingots: the alloy ingots that have been smelted are powdered to obtain alloy powders;

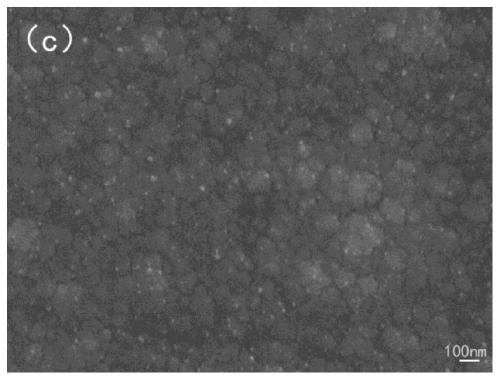

[0033] (4) powder sintering treatment: the alloy powder is sintered;

[0034] (5) Hot isostatic pressing treatment: the sintered alloy powder obtained in step (4) is subjected to hot isostatic pressing treatment, and then taken out of the furnace to obtain an alloy target material.

[003...

Embodiment 2

[0036] Example 2. This example is a further limitation of Example 1, specifically describing the preparation method of Fe, Al, Co, Cu, Cr, Mn alloy targets.

[0037] (1) Selection and proportioning of raw materials: In this embodiment, Fe, Al, Co, Cu, Cr, and Mn are selected as bulk and granular metals with a purity higher than 99.9%, and are mixed according to the ratio of atomic equimolar ratios to obtain etc. Alloy raw material composition in molar ratio;

[0038] (2) Alloy smelting: The WK-П non-consumable vacuum smelting furnace is then used to prepare high-entropy alloy ingots. The smelting is carried out in an argon atmosphere at 1 atmosphere, the smelting current is 250A, and the number of smelting times is 5-8 times. Obtain alloy ingots; smelt 5 to 8 times to obtain alloy ingots with uniform distribution of raw material components;

[0039] (3) Powdering of alloy ingots: the alloy ingots are first refined and crushed by mechanical stamping, and then the alloy ingots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com