Method for improving tap density of composite anode material xLiFePO4.yLi3V2(PO4)3 of lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of increased tap density, improved energy density, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

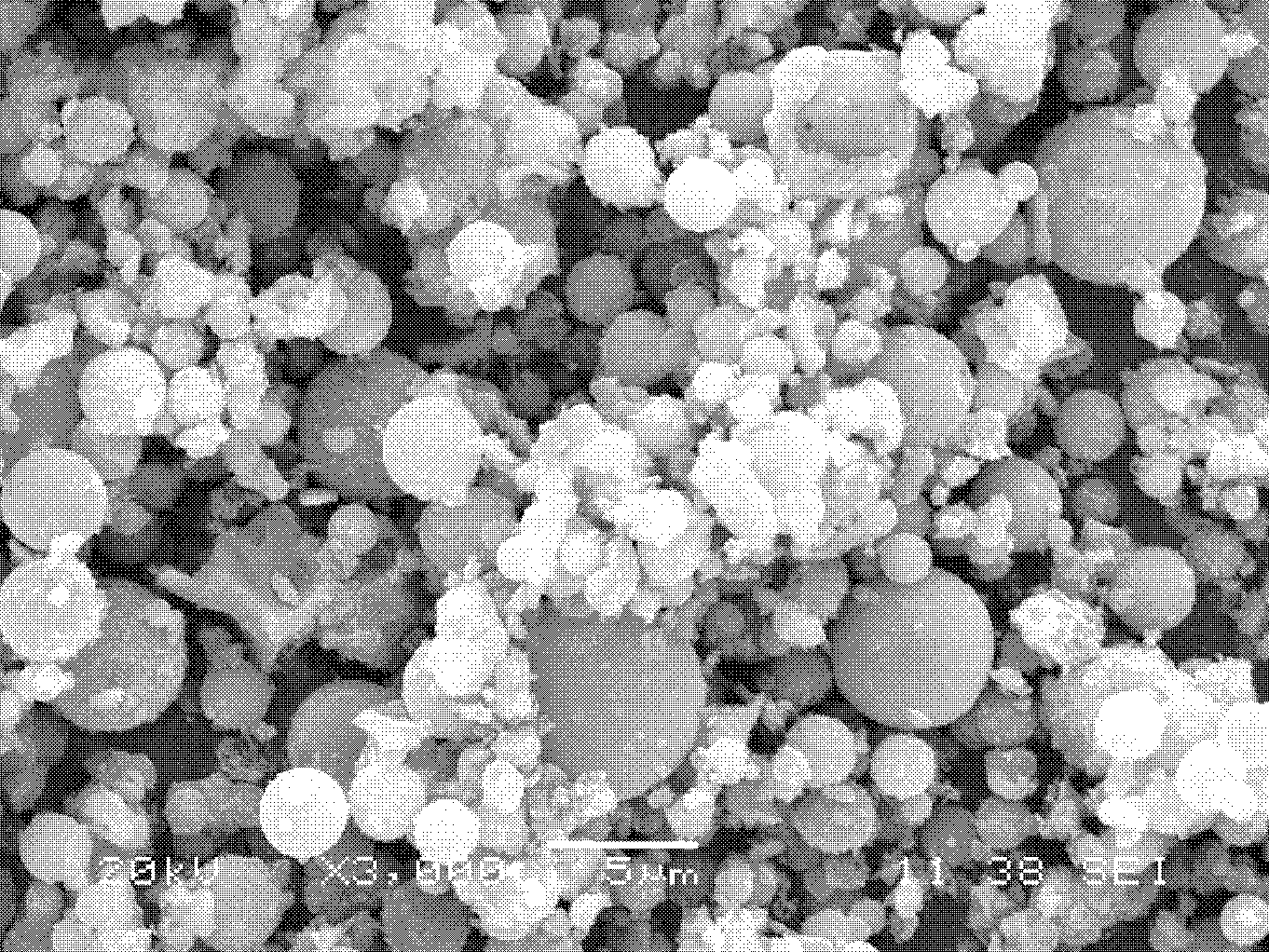

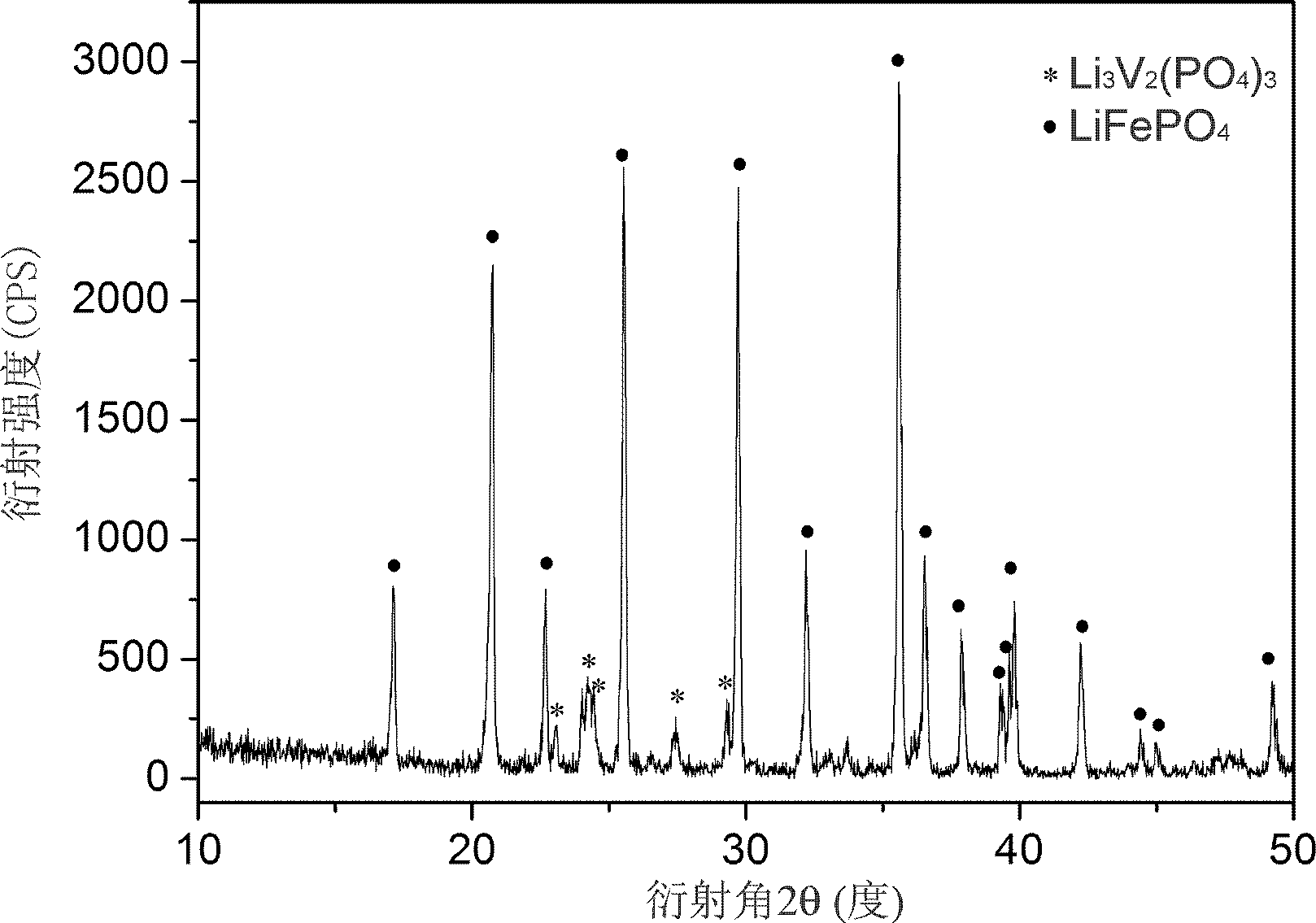

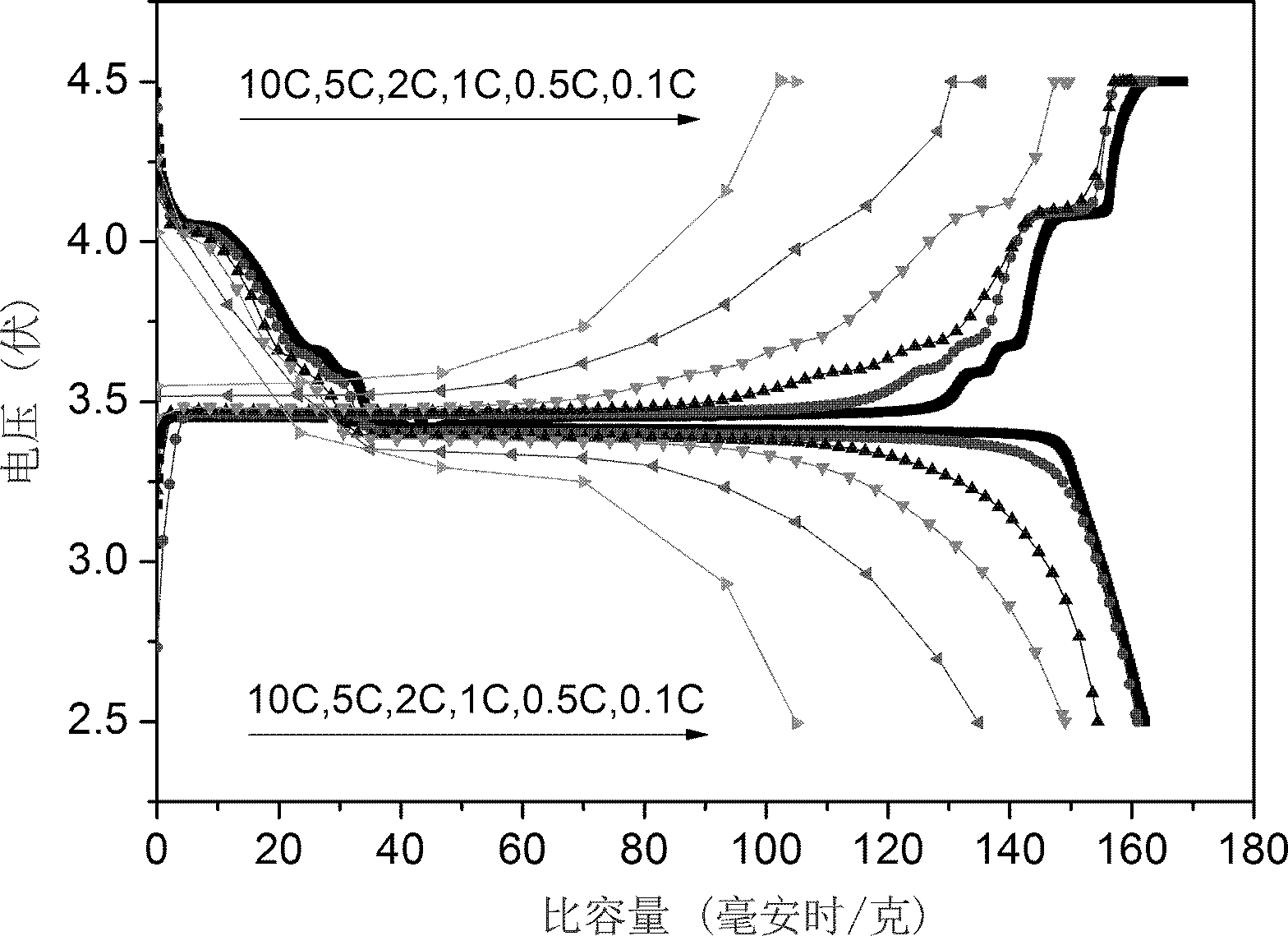

[0024] Using lithium acetate, ferrous oxalate, ammonium vanadate and phosphoric acid as raw materials, press 0.8LiFePO 4 0.2 Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of ingredients, adding citric acid (the molar amount of which is 1 times the total molar number of metal ions), and then adding an appropriate amount of deionized water to make the pH of the mixed solution 4, stirred in a constant temperature water bath at 80°C for 10 hours until the formation of Sol, the resulting sol is diluted with deionized water (the amount of deionized water is 10 times the volume of the sol), spray-dried at 150°C, and then the obtained powder is calcined at 800°C for 4 hours in an argon atmosphere to obtain a composite positive electrode material 0.8LiFePO 4 0.2 Li 3 V 2 (PO 4 ) 3 , its tap density reaches 1.92g / cm 2 .

Embodiment 2

[0026] Using lithium carbonate, iron phosphate, vanadium peroxalate and diammonium hydrogen phosphate as raw materials, press 0.5LiFePO 4 0.5Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of ingredients, adding polyethylene glycol (its molar weight is 0.5 times the total molar number of metal ions), then adding an appropriate amount of ethanol to make the pH of the mixed solution is 2, stirred in a constant temperature oil bath at 70 ° C for 0.5 hours to Form a sol, dilute the obtained sol with deionized water (the amount of deionized water is 20 times the volume of the sol), spray dry it at 300°C, and then calcinate the obtained powder at 650°C for 12 hours in an argon atmosphere to obtain a composite positive electrode Material 0.5LiFePO 4 0.5Li 3 V 2 (PO 4 ) 3 , its tap density reaches 1.87g / cm 2 .

Embodiment 3

[0028] Using lithium hydroxide, ferric oxide, triethanolamine vanadium peroxide, and triammonium phosphate as raw materials, press 0.01LiFePO 4 0.99 Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of ingredients, adding oxalic acid (its molar mass is 3 times the total molar mass of metal ions), then adding an appropriate amount of acetone to make the pH value 6, stirring in a constant temperature oil bath at 20°C for 12 hours until a sol was formed, and the resulting sol Dilute with deionized water (the amount of deionized water is 50 times the volume of the sol), spray dry at 100°C, and then calcinate the obtained powder at 850°C for 2 hours in an argon atmosphere to obtain a composite positive electrode material 0.01LiFePO 4 0.99 Li 3 V 2 (PO 4 ) 3 , its tap density reaches 1.90g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com