Alloy material of centrifugal refrigerating compressor impeller and preparation method thereof

A technology of refrigeration compressors and centrifugal compressors, applied in the field of alloy materials, can solve the problems of affecting the moment of inertia of the rotor group, complex processing technology, and large specificity of alloy steel, etc., to prevent scattered shrinkage defects, simple process, and thermal crack resistance Tendency to strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

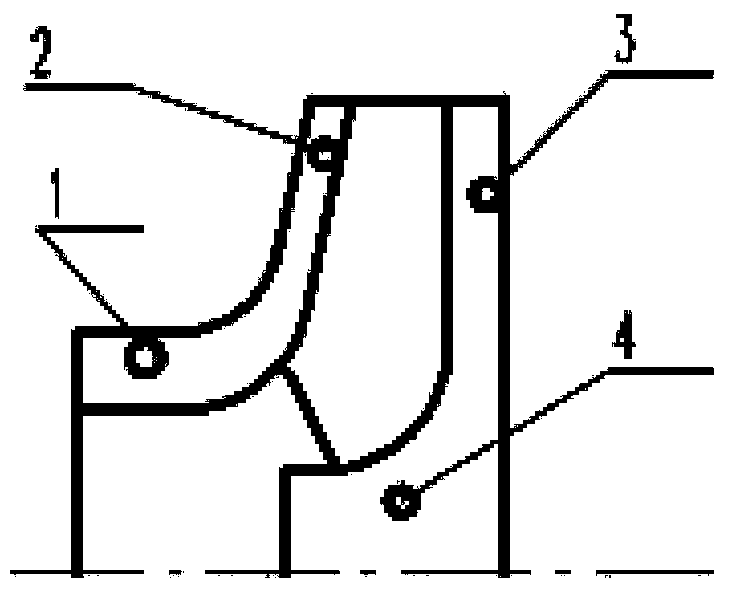

Image

Examples

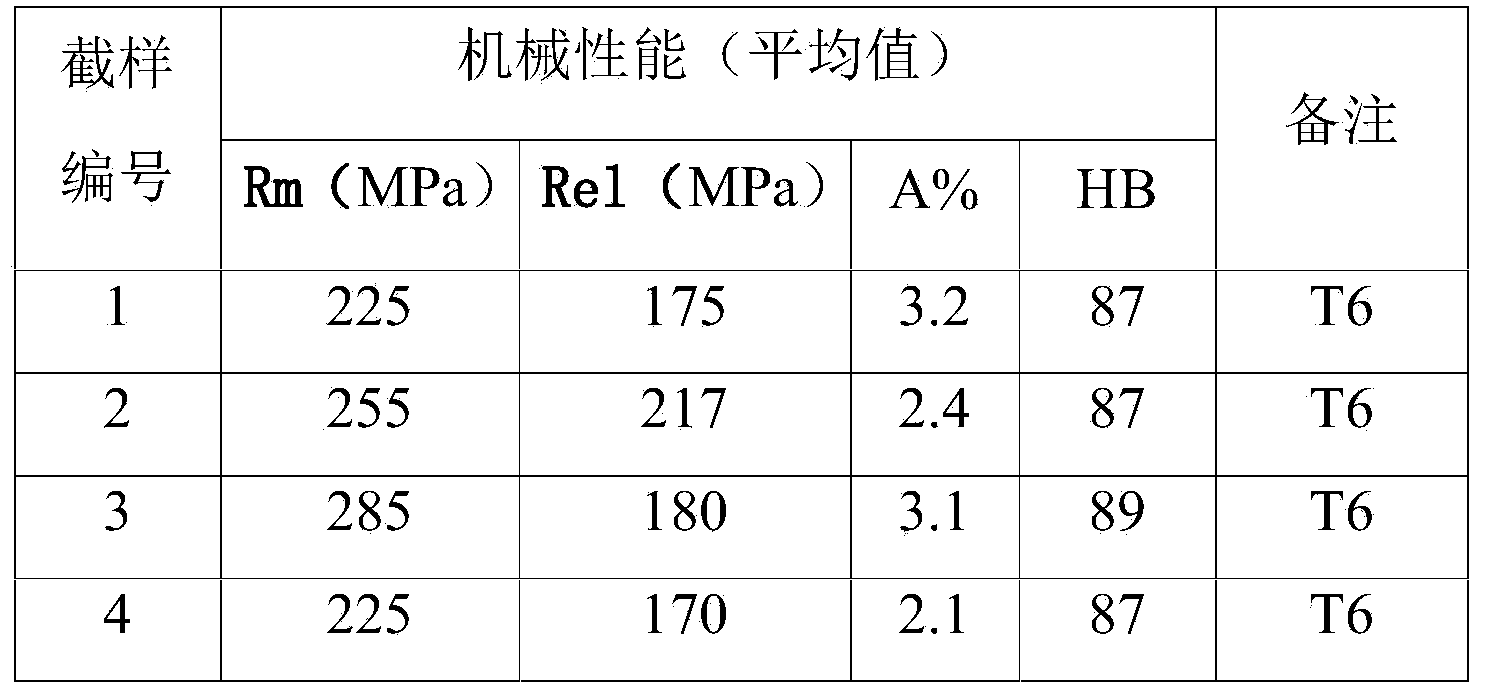

Embodiment 1

[0041] A centrifugal refrigeration compressor impeller alloy material, the alloy material comprises the following components by weight: Si8%, Cu2%, Mg0.5%, Zr0.3%, Fe0.3%, Zn0.2%, Ti0. 1%, the balance of Al and impurity elements.

[0042] The preparation method of the centrifugal refrigeration compressor impeller alloy material comprises the following steps:

[0044] Evenly coat talc and water glass in the crucible;

[0045] After heating up, add aluminum ingots preheated to 200°C, Al-Cu master alloys containing 50% copper and Al-Si master alloys containing 25% silicon, accounting for 60% of the total weight. ;

[0046] When the furnace temperature rises to 700 ℃, press the Mg preheated to 200 ℃, and the melting is completed; when the furnace temperature rises to 730 ℃, the refining agent preheated to 200 ℃ (SRWJ1 type hexachloroethane refining agent, Prepared according to 0.5% of the weight of the charge), press into the molten aluminum, stir s...

Embodiment 2

[0051] A centrifugal refrigeration compressor impeller alloy material, the alloy material comprises the following components by weight: Si10%, Cu1%, Mg0.2%, Zr0.2%, Fe0.2%, Zn0.1%, Ti0. 05%, the balance of Al and impurity elements.

[0052] The preparation method of the centrifugal refrigeration compressor impeller alloy material comprises the following steps:

[0054] Evenly coat talc and water glass in the crucible;

[0055] After heating up, add aluminum ingots preheated to 300°C, Al-Cu master alloys containing 50% copper and Al-Si master alloys containing 25% silicon, accounting for 70% of the total weight. ;

[0056] When the furnace temperature rises to 720 ℃, press the Mg preheated to 300 ℃, and the melting is completed; when the furnace temperature rises to 750 ℃, the refining agent preheated to 300 ℃ (SRWJ1 type hexachloroethane refining agent, Prepared according to 0.5% of the weight of the charge), press into the molten aluminum, stir...

Embodiment 3

[0061] A centrifugal refrigeration compressor impeller alloy material, the alloy material includes the following components by weight percentage: Si9%, Cu1.5%, Mg0.3%, Zr0.25%, Fe0.25%, Zn0.15%, Ti0.1%, the balance of Al and impurity elements.

[0062] The preparation method of the impeller alloy material of the centrifugal refrigeration compressor comprises the following steps:

[0064] Evenly coat talcum powder and water glass in the crucible;

[0065] After heating up, add aluminum ingots preheated to 250°C, Al-Cu master alloy containing 50% copper and Al-Si master alloy containing 25% silicon, accounting for 65% of the total weight, and add the remaining aluminum ingots after heating up to melt ;

[0066] When the furnace temperature rises to 710°C, press in the Mg preheated to 250°C, and the melting is completed; raise the furnace temperature to 740°C, and put the refining agent (SRWJ1 type hexachloroethane refining agent, Prepared accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com