Casting method of zinc base alloy for stamping die basal body

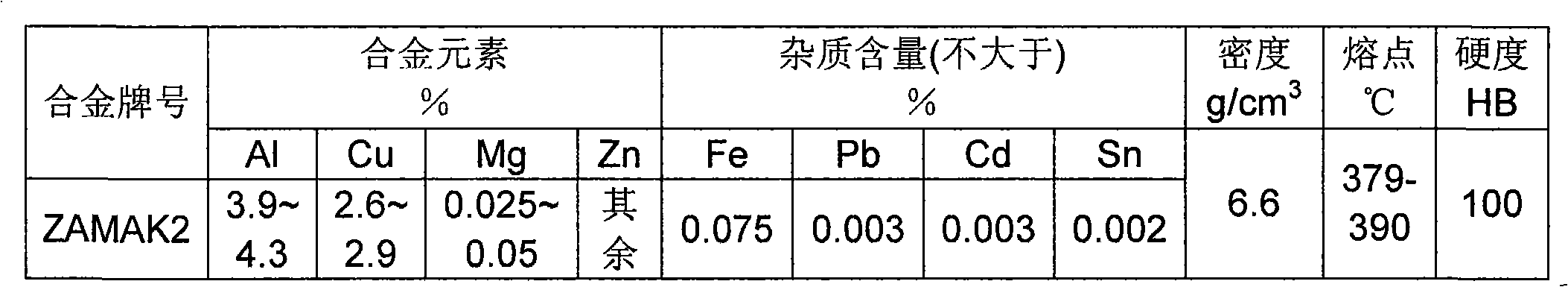

A stamping die and zinc-based technology, which is applied in the field of mold manufacturing for large-scale outer cover parts of automobiles, can solve the problems of complex shape, high cost, and low yield, and achieve the effects of fast casting speed, low cost, and simple smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

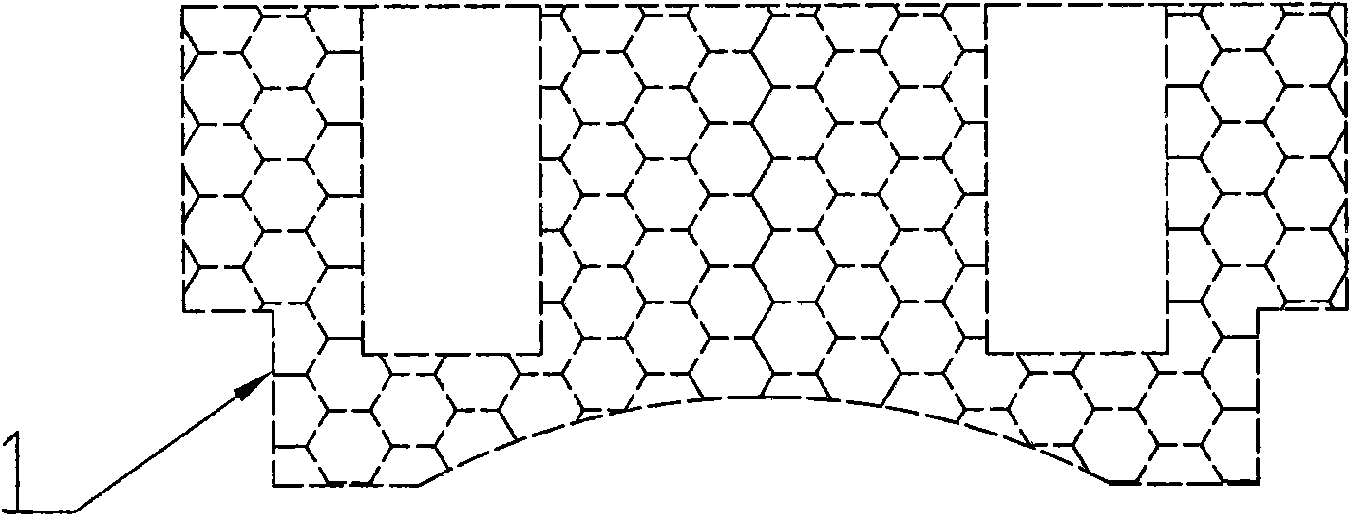

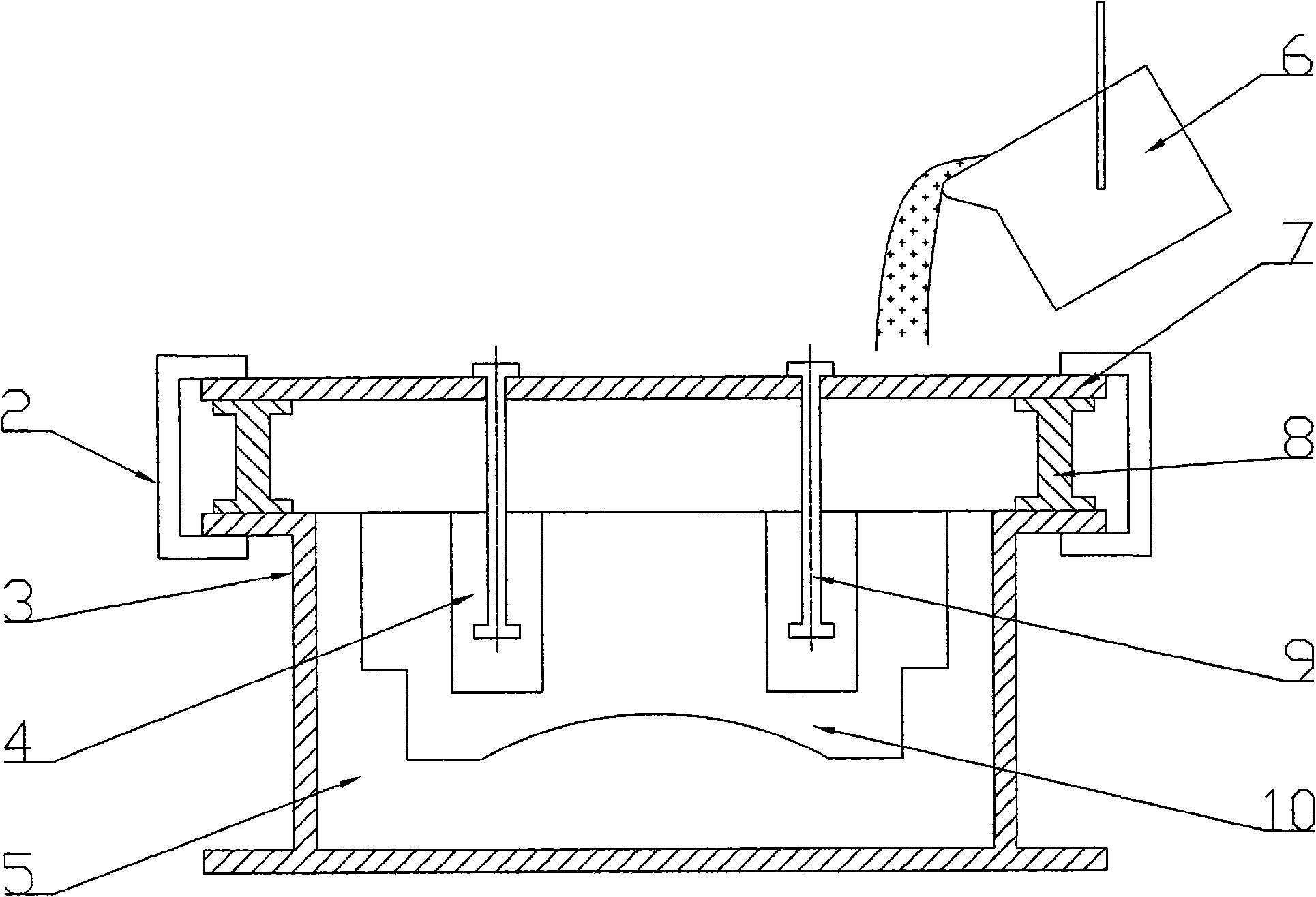

[0015] to combine figure 1 and figure 2 The disclosed embodiments illustrate the invention in detail.

[0016] for making as figure 1 As shown in the shape of the mold, the whole casting process is mainly divided into two parts: pouring liquid production and casting production.

[0017] 1. Casting liquid production (melting):

[0018] Add the zinc alloy ingot or the reused zinc-based alloy mold into the electric furnace (it can also be added by mixing), heat until it is completely melted, continue to heat up to 420°C-480°C (preferably about 450°C) out of the furnace, and pour the zinc alloy liquid into the ladle 6 for preparation Pouring (melting time varies according to the power and tonnage of the electric furnace, and the melting time of a 1.5-ton electric furnace at 150KW / H is about 30 minutes).

[0019] The melting process is the preparatory work for subsequent casting production.

[0020] 2. Casting production: casting production is divided into the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com