Preparation method of lithium ion power battery cathode

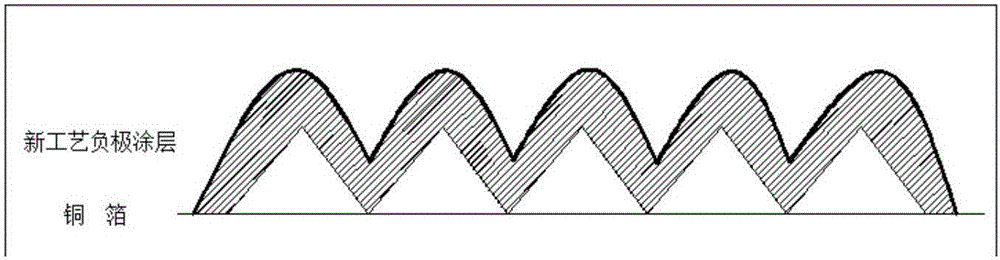

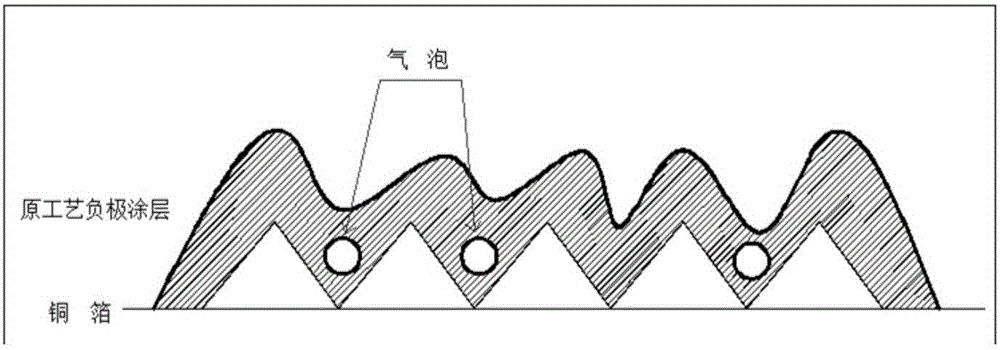

A power battery and lithium-ion technology, which is applied in the field of negative electrode preparation of lithium-ion power batteries, can solve problems such as bubble stirring time, achieve good wettability and fluidity, improve wetting coating performance, and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Glue making. First add a certain amount of deionized water into the No. 1 mixer, and then evenly add a certain amount of CMC powder, so that the concentration of the CMC glue is 2.3%. Stir for 5 minutes at a revolution speed of 43 rpm; then stir for 10 minutes at a revolution speed of 20 rpm and a dispersion speed of 1800 rpm; then stir for 120 minutes at a revolution speed of 15 rpm and a dispersion speed of 3000 rpm.

[0041] 2. Leave it on hold for 120 minutes, and vacuumize the No. 1 mixer to -0.1Mpa.

[0042] 3. Add graphite and sp powder to No. 2 blender, and dry mix. Stir for 25 minutes at a revolution speed of 20 rpm and a dispersion speed of 1200 rpm.

[0043] 4. Add the CMC glue prepared by No. 1 mixer to No. 2 mixer, stir for 3 minutes at a revolution speed of 10 rpm, a dispersion speed of 500 rpm, and scrape the barrel once; continue stirring, and stir for 30 minutes at a revolution speed of 30 rpm and a dispersion speed of 1500 rpm, every 10 Scrape th...

Embodiment 2

[0052]1. Glue making. First add a certain amount of deionized water into the No. 1 mixer, and then evenly add a certain amount of CMC powder, so that the concentration of the CMC glue is 2.5%. Stir at a revolution speed of 38rpm for 3 minutes; then stir at a revolution speed of 18rpm and a dispersion speed of 1500rpm for 5 minutes; then stir at a revolution speed of 18rpm and a dispersion speed of 2500rpm for 100 minutes.

[0053] 2. Leave it aside for 100 minutes, and vacuumize the No. 1 mixer to -0.15Mpa.

[0054] 3. Add graphite and sp powder to No. 2 blender, and dry mix. Stir for 20 minutes at a revolution speed of 25 rpm and a dispersion speed of 1000 rpm.

[0055] 4. Add the CMC glue prepared by No. 1 mixer to No. 2 mixer, stir for 4 minutes at a revolution speed of 12rpm, a dispersion speed of 300rpm, and scrape the bucket once; continue to stir, stir for 35 minutes at a revolution speed of 25rpm, and a dispersion speed of 1800rpm, every 10 Scrape the bucket every m...

Embodiment 3

[0063] 1. Glue making. First add a certain amount of deionized water into No. 1 mixer, and then evenly add a certain amount of CMC powder to make the concentration of the CMC glue solution 2.9%. Stir at a revolution speed of 45 rpm for 10 minutes; then stir at a revolution speed of 25 rpm and a dispersion speed of 2000 rpm for 8 minutes; then stir at a revolution speed of 20 rpm and a dispersion speed of 3500 rpm for 150 minutes.

[0064] 2. Leave it on hold for 110 minutes, and vacuumize the No. 1 mixer to -0.2Mpa.

[0065] 3. Add graphite and sp powder to No. 2 blender, and dry mix. Stir for 30 minutes at a revolution speed of 28 rpm and a dispersion speed of 1500 rpm.

[0066] 4. Add the CMC glue prepared by No. 1 mixer to No. 2 mixer, stir for 5 minutes at a revolution speed of 15rpm, and a dispersion speed of 600rpm, and scrape the bucket once; continue stirring, and stir for 40 minutes at a revolution speed of 28rpm, and a dispersion speed of 2000rpm, every 10 Scrape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com