In-pipe concrete vacuum auxiliary filling method for large concrete-filled steel tubular structure and filling method

A technology of concrete-filled steel tubes and auxiliary systems, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems that affect the service performance of concrete-filled steel tube structures, cannot realize concrete pouring construction, and reduce the plasticity and fluidity of cement paste. Achieve the effect of improving mechanical properties and performance, reducing the number of defects, and reducing the number of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings, embodiments and test examples. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

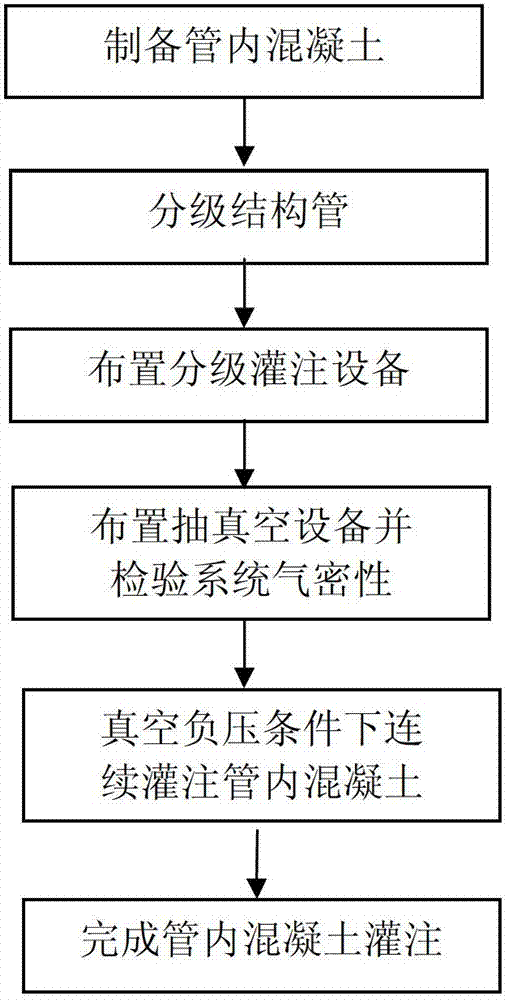

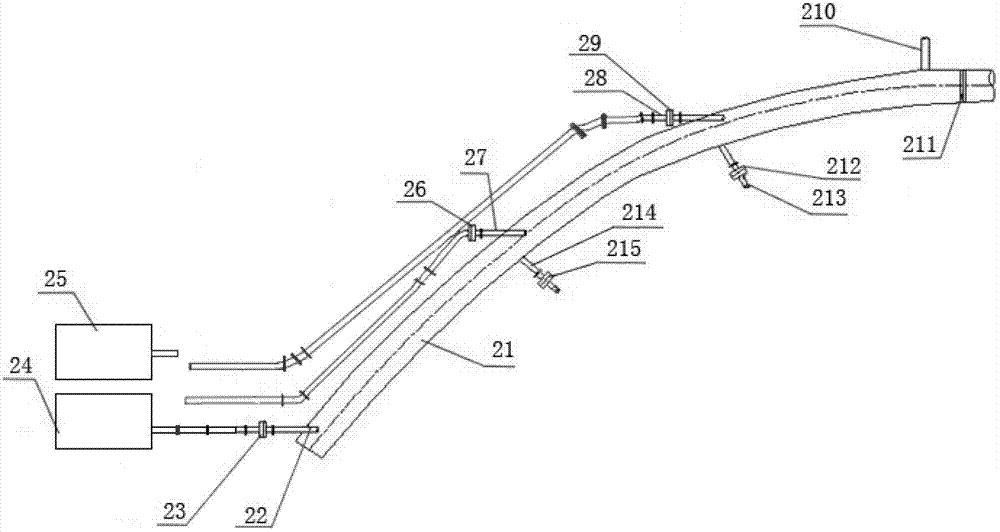

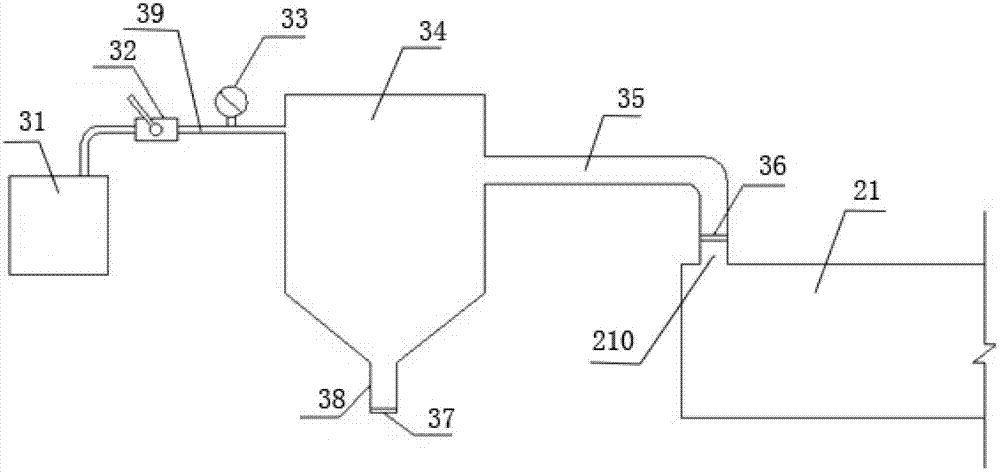

[0059] Such as figure 1 As shown, a vacuum-assisted pouring method for concrete in a large-scale concrete-filled steel tube structure (this embodiment is used for pouring the arch of a large-span concrete-filled steel tube arch bridge with a span of 500m), including the following steps:

[0060] (1) Preparation of high-performance concrete: use high-performance polycarboxylate water reducer, expansion agent and water reducer, adjust the mix ratio according to different concrete grades, so that the concrete slump reaches 180mm-240mm, the initial setting time 6 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com