Composite clarifying agent, composition for neutral borosilicate medicinal glass as well as glass prepared from composition, and applications

A composite clarifying agent and medicinal glass technology, applied in the field of glass manufacturing, can solve the problems of reducing the content of harmful heavy metals in neutral borosilicate glass containers, failing to meet safety requirements, reducing the surface tension of neutral borosilicate glass liquid, etc., to achieve effective Conducive to drug safety, reducing the content of harmful heavy metals, clarifying the effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the above preparation method, the raw materials can be used after premixing, which specifically includes:

[0035] a. Pre-mixing: first pre-mixing at least part of the quartz sand and at least part of the composite clarifier;

[0036] b. Add batching materials: add the pre-mixed materials as a raw material according to the proportion, mix well and set aside;

[0037] c. Put the above-mentioned uniformly mixed materials into a quartz crucible, keep warm at 1400-1450°C for 40-80 minutes, rise to 1580-1620°C for 120-180 minutes in 20-50 minutes, take out the crucible and keep warm at 530-570°C for 30-80 minutes Minutes for annealing treatment, and then lowered to room temperature with the furnace to prepare the neutral borosilicate medical glass.

[0038] In a specific embodiment of the present invention, the composite clarifying agent is weighed according to the proportion, 100 parts of quartz sand and 10 parts of composite clarifying agent are pre-mixed evenly with a...

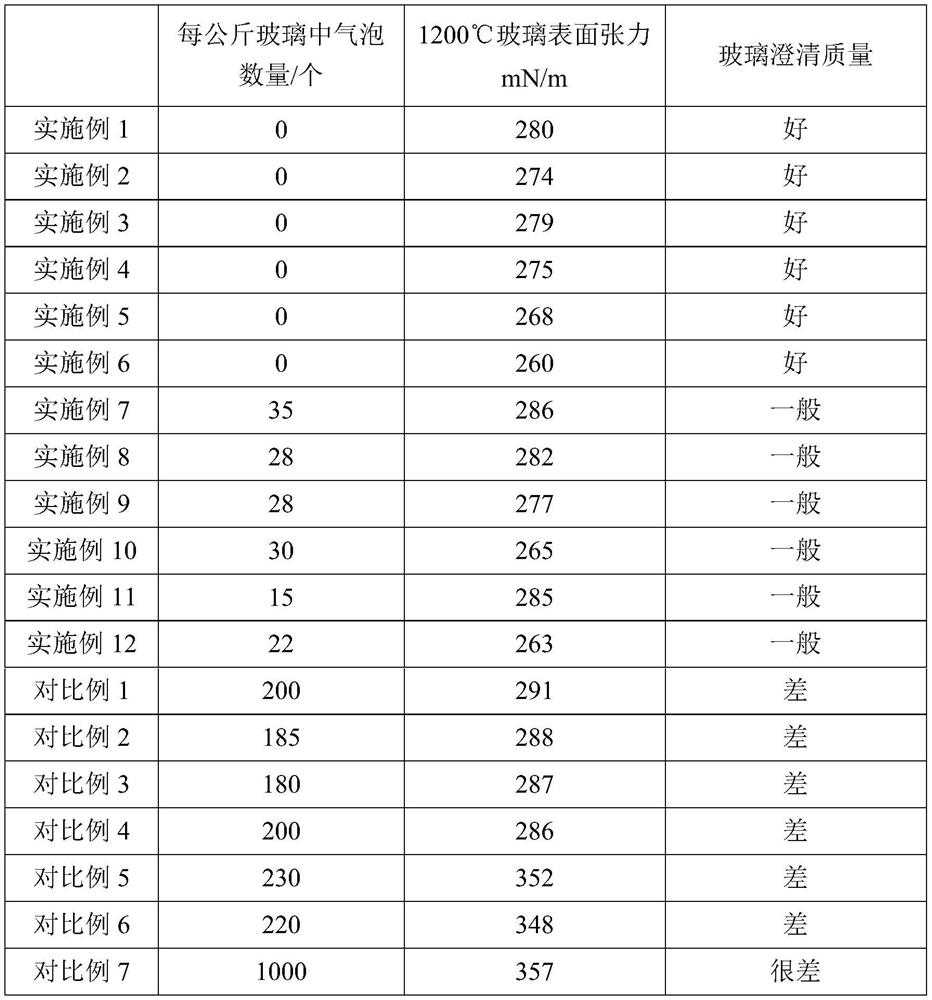

Embodiment 1-12

[0045] The composite clarifying agent is weighed according to the ratio shown in the following table 1, 100 parts by weight of quartz sand and 10 parts by weight of composite clarifying agent are pre-mixed evenly with a small mixer, and the pre-mixed composite clarifying agent is used as The raw materials are added into the above-mentioned neutral borosilicate glass batch according to the calculated ratio (relative to 100 weight of neutral borosilicate glass batch, the addition amount of the composite clarifier is 0.8 parts by weight), mixed evenly, put into a quartz crucible, and Heat at 1430°C for 60 minutes, rise to 1600°C for 150 minutes in 30 minutes, take out the crucible and hold at 550°C for 60 minutes for annealing treatment, and then cool down to room temperature with the furnace to produce neutral borosilicate glass.

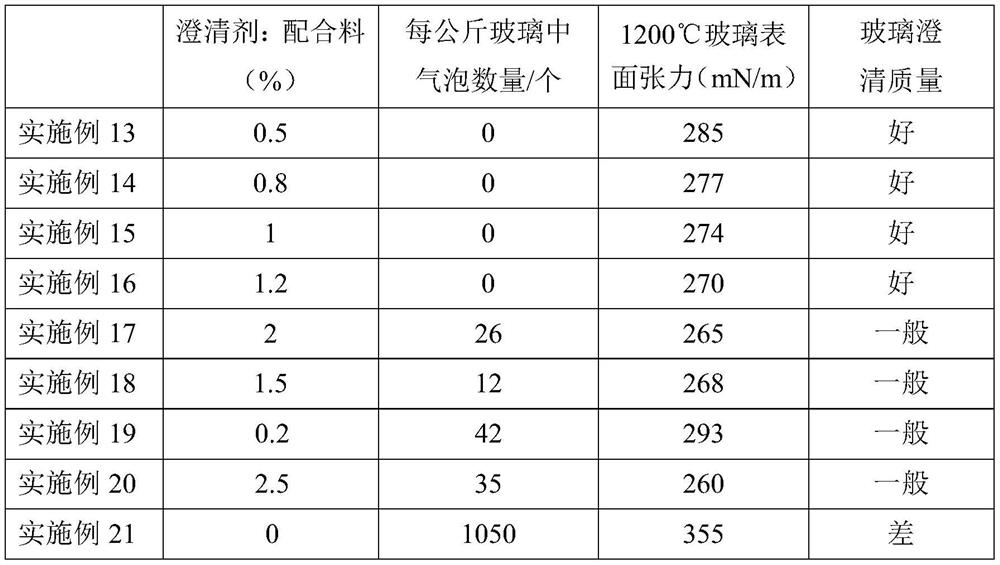

Embodiment 13-21

[0049] Carried out under the same conditions as in Example 11, the ratio of chloride salt: fluoride salt: cerium oxide in the composite clarifier is 1: 1.5: 2.5, the difference is: relative to 100 weight of neutral borosilicate glass batch material, according to Add the composite clarifying agent in the ratio shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com