Process and kiln for producing high-performance alkali-free glass

A glass and process technology, applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve problems such as difficult production, collapse of large canes, and inability to produce normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

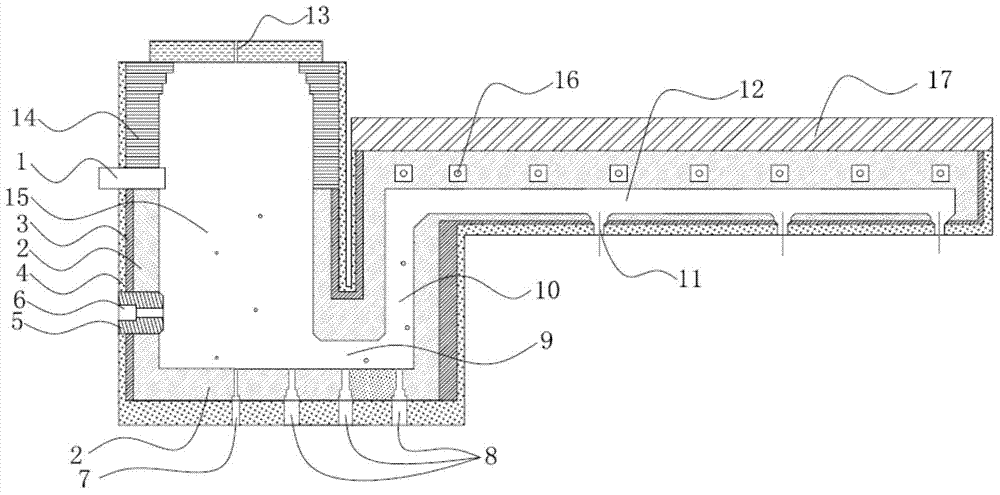

[0023] In order to facilitate readers to better understand the present invention, to facilitate users to maintain and repair the products of the present invention, and to provide references for maintenance and repair researchers, mature embodiments are described below in conjunction with the accompanying drawings.

[0024] A process for producing glass with an alkali metal content of less than 0.5%, comprising the following steps in sequence: (1) burning oxygen to preheat glass raw materials to 600°C to 900°C to form a eutectic sinter; (2) electrically heating the low Eutectic sintering to above 1650°C to form molten glass; (3) electric heating to keep the temperature of molten glass above 1450°C; (4) clarification of molten glass; (5) molding of the clarified molten glass through a platinum bushing to produce glass Fibrous strands. The above step (3) can be omitted as appropriate.

[0025] The high-performance alkali-free glass furnace of the present invention includes a mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com