Quick discharging method for tiny bubbles from optical fiber coating

A coating and optical fiber technology, applied in the field of rapid discharge of tiny air bubbles in optical fiber coatings, can solve the problems of inability to discharge tiny air bubbles in optical fiber coatings, poor removal of tiny air bubbles, and inability of devices to discharge tiny air bubbles, etc., so as to improve cladding optics. performance, reducing the number of air bubbles and coating defects, reducing the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

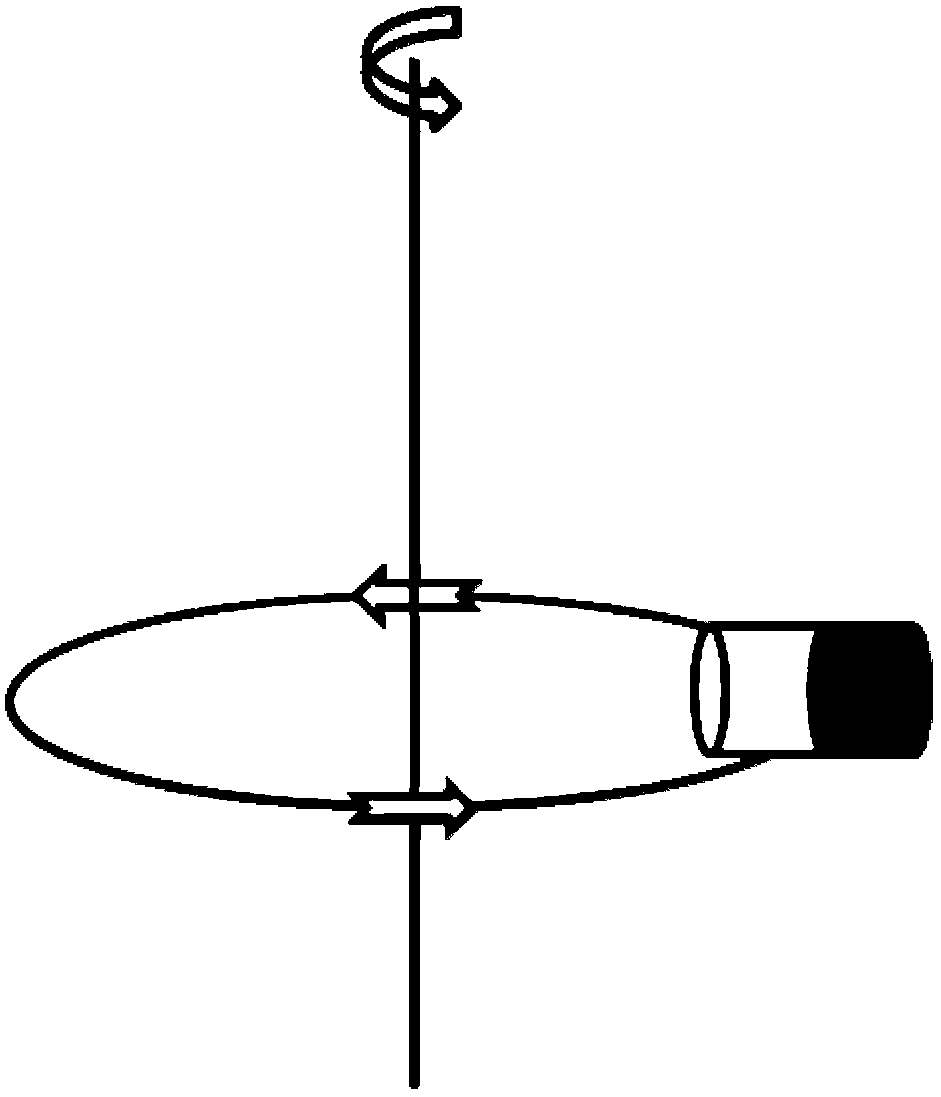

[0034] Lead the optical fiber coating into a closed coating tank, which is made of stainless steel and sealed by a rubber ring; heat the optical fiber coating to 30°C and keep it warm, and vacuum the closed coating tank to 1x10 -4 Pa vacuum degree to maintain the vacuum degree; the central axis of the closed paint tank is inclined to a certain angle with respect to the rotation axis, see figure 1 As shown, the airtight paint tank is made centrifugal movement around the rotating shaft, and the optical fiber paint is always at the bottom of the airtight paint tank. The centrifugal speed is accelerated from 0rpm until the centrifugal speed reaches 500rpm; the centrifugal speed is maintained at 500rpm for 25 minutes and the optical fiber paint Always stay at the bottom of the airtight paint tank, and then decelerate the centrifugal speed from 500rpm to 0rpm until there is at most one tiny bubble with a diameter of 0.01-0.15mm per cubic centimeter of fiber coating, and no larger bubbl...

Embodiment 2

[0036] Lead the optical fiber coating into the airtight coating tank, which is made of aluminum alloy and sealed by a rubber ring; heat the optical fiber coating to 35°C and keep it warm, and vacuum the airtight coating tank to a vacuum of 0.5 Pa to maintain the Vacuum degree; the central axis of the airtight paint tank is inclined at a certain angle relative to the rotation axis, see figure 1 As shown, the airtight paint tank is made centrifugal movement around the rotating shaft, the optical fiber paint is always at the bottom of the airtight paint tank, the centrifugal speed is accelerated from 0rpm, until the centrifugal speed reaches 2000rpm; maintain the centrifugal speed of 2000rpm for 15 minutes, the optical fiber paint Always stay at the bottom of the airtight paint tank, and then decelerate the centrifugal speed from 2000rpm to 0rpm until there is at most one tiny bubble with a diameter of 0.01~0.15mm per cubic centimeter of optical fiber coating, and no larger bubbles...

Embodiment 3

[0038] Lead the optical fiber coating into a closed coating tank, which is made of light-proof plastic and sealed by a rubber ring; heat the optical fiber coating to 40°C and keep it warm, and vacuum the closed coating tank to a vacuum degree of 1 Pa to maintain the Vacuum degree; the central axis of the airtight paint tank is inclined at a certain angle relative to the rotation axis, see figure 1 As shown, the airtight paint tank is made centrifugal movement around the rotating shaft, the optical fiber paint is always at the bottom of the airtight paint tank, the centrifugal speed is accelerated from 0rpm, until the centrifugal speed reaches 5000rpm; maintain the centrifugal speed of 5000rpm for 10 minutes, the optical fiber paint Always stay at the bottom of the airtight paint tank, then reduce the centrifugal speed from 5000rpm to 0rpm until there is at most one tiny bubble with a diameter of 0.01~0.15mm in each cubic centimeter of optical fiber coating, and no larger bubble ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com