An inkjet printing nozzle

A technology of inkjet printing and nozzles, which is applied in the field of inkjet printing nozzles, can solve the problems of reducing the display effect and low uniformity of the film layer, and achieve the effect of improving the uniformity and uniform thickness of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As mentioned in the background technology, when the inkjet printing technology is used to print the film layer of the display in the prior art, the uniformity of the film layer is low, thereby reducing the display effect. The inventor found that the reason for this problem is that the ink spraying After being placed on the substrate, because the edge of the ink dries quickly, and the middle of the ink is thick, a film layer with a thick center and a thin edge is formed, and the film layer contains bubbles, which reduces the uniformity of the film layer and reduces the display. Effect.

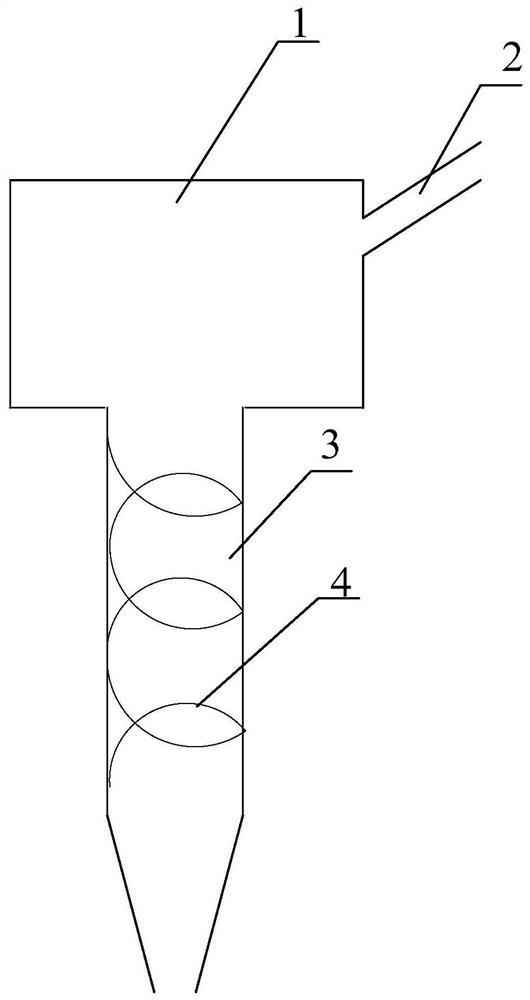

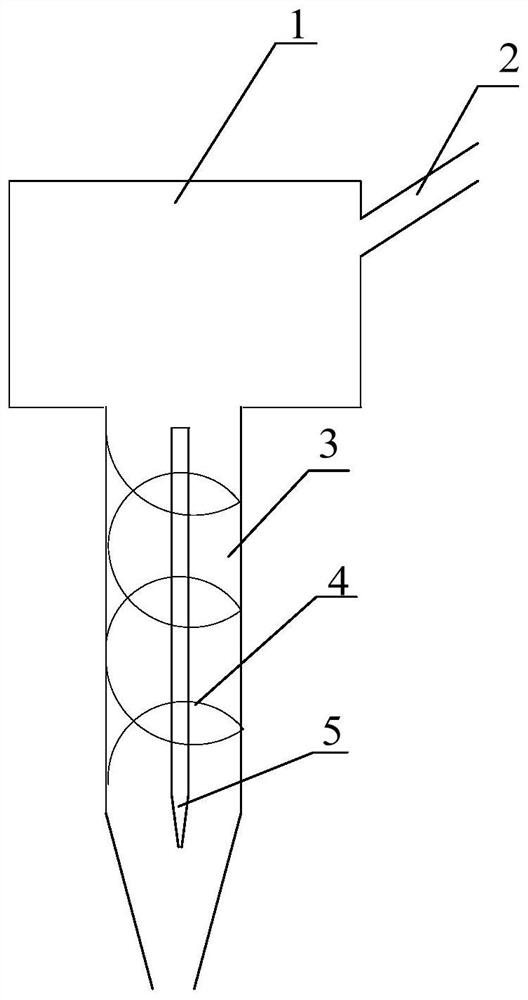

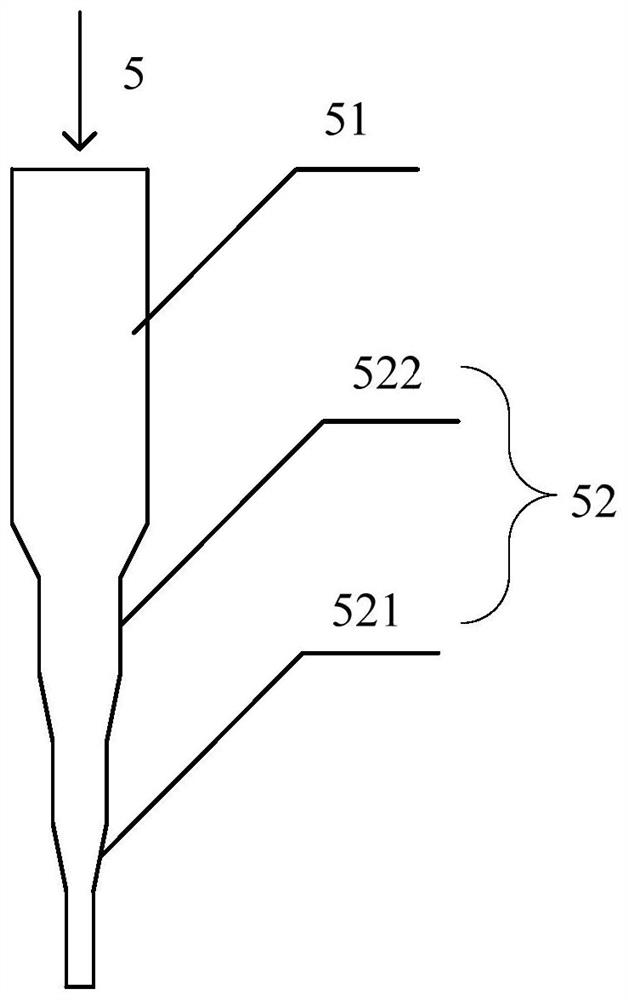

[0024] Based on this, the present invention provides an inkjet print nozzle, by setting the helical blade inside the nozzle, when the inkjet printing device sprays ink, when the ink passes through the helical blade inside the nozzle, the bubbles in the ink will quickly rotate on the helical blade Movement, so that the air bubbles are fragmented and separated from the ink. When the ink is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com