Foaming defect diagnosis method, device and equipment and storage medium

A defect diagnosis and defect technology, applied in the field of defect detection, can solve the problems of factory economic loss, low qualification rate of refrigerator products, high foaming bubble rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

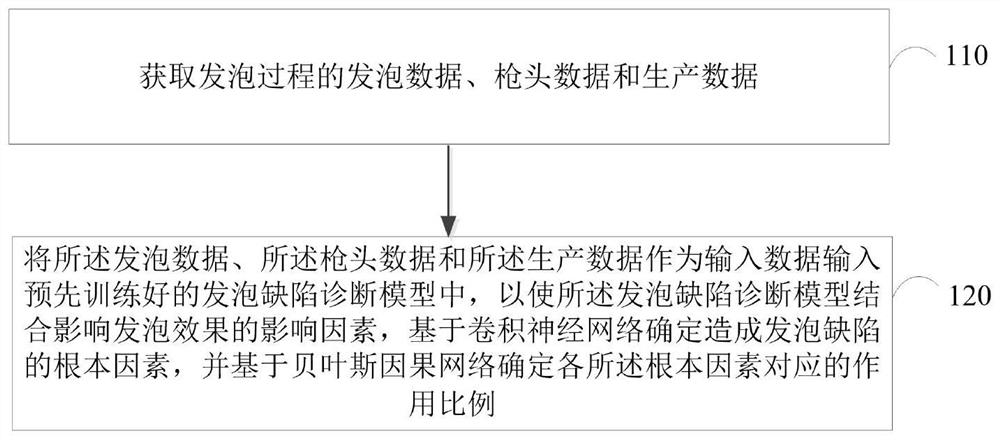

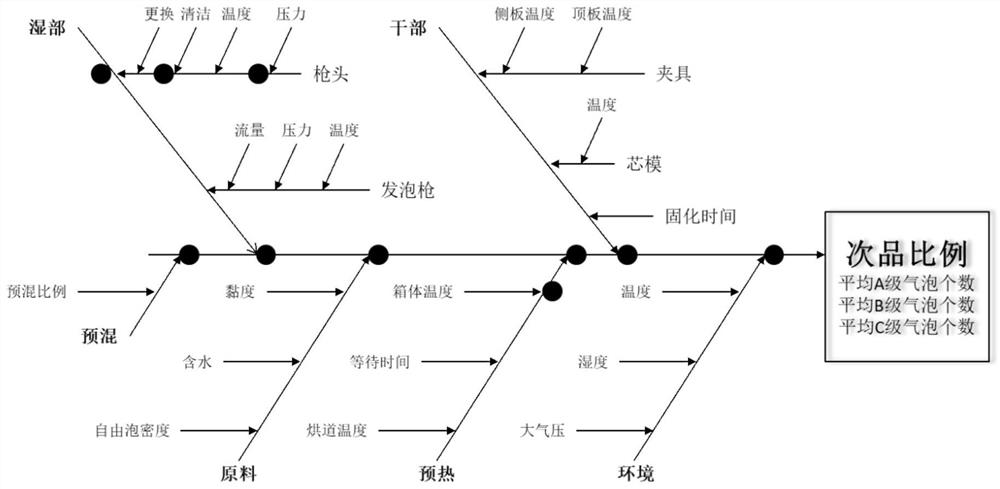

[0056] figure 1 It is a flow chart of a method for diagnosing foaming defects provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where it is necessary to analyze and determine the root factors leading to foaming defects and the action ratio of each root factor. Bubble defect diagnosis means to perform, such as figure 1 As shown, it specifically includes the following steps:

[0057] Step 110, acquiring foaming data, gun head data and production data of the foaming process.

[0058] Among them, the foaming data includes environmental data and material data. Environmental data may include data acquired by environmental sensors located in various links of the foaming process, specifically including: ambient temperature, ambient humidity, ambient air pressure, and WIP codes. Material data can include material sensing data obtained by material sensors located in each link of the foaming process, specifically including warm-up time, ...

Embodiment 2

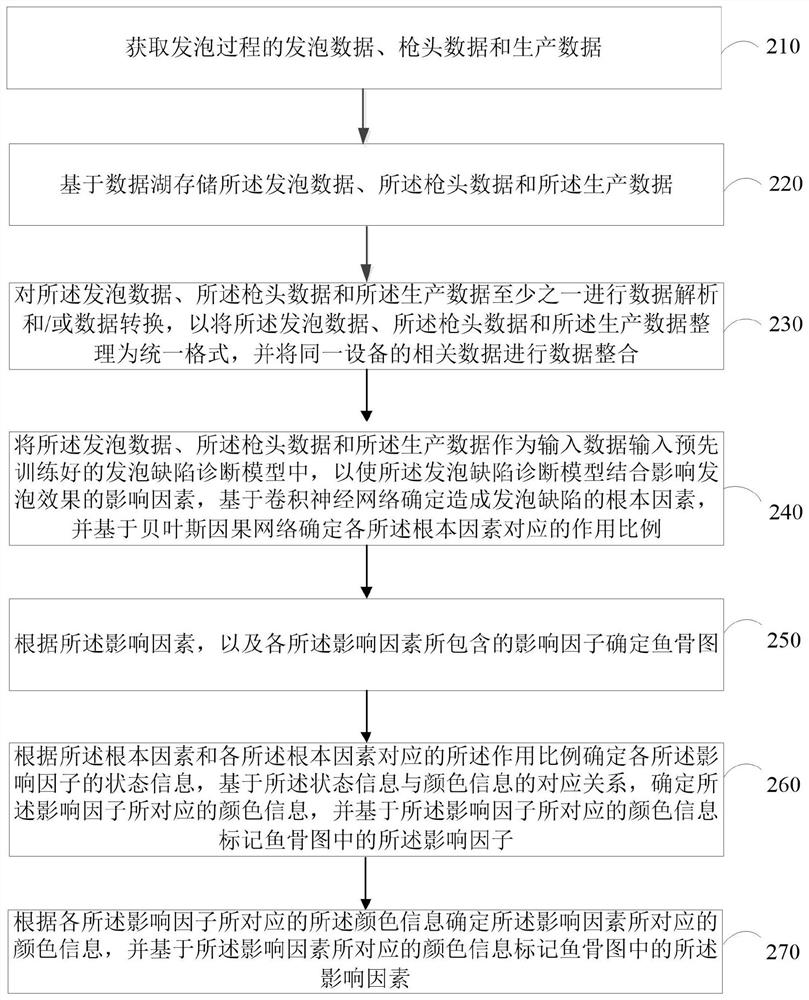

[0071] figure 2 It is a flow chart of a method for diagnosing foaming defects provided by Embodiment 2 of the present invention. This embodiment is embodied on the basis of the foregoing embodiments. Such as figure 2 As shown, in this embodiment, the method may also include:

[0072] Step 210, acquiring foaming data, gun head data and production data of the foaming process.

[0073] Wherein, the foaming data includes environmental data and material data of the foaming process, and the material data includes material state data and material barcode data.

[0074] In one embodiment, step 210 may specifically include:

[0075] Determine the data collected by the environmental sensors located in each link of the foaming process as environmental data; determine the data collected by the material sensors located in each link of the foaming process as material state data; determine the data scanned by the mobile material barcode gun It is determined as the material barcode data...

Embodiment 3

[0118] Figure 5 It is a structural schematic diagram of a foaming defect diagnosis device provided in Embodiment 3 of the present invention, which can be applied to situations where it is necessary to analyze and determine the root factors leading to foaming defects and the action ratio of each root factor. The device can be realized by software and / or hardware, and is generally integrated in computer equipment.

[0119] Such as Figure 5 As shown, the device includes:

[0120] An acquisition module 510, configured to acquire foaming data, gun tip data and production data of the foaming process;

[0121] Executing module 520, configured to input the foaming data, the gun head data and the production data as input data into the pre-trained foaming defect diagnosis model, so that the foaming defect diagnosis model can be combined with the The influencing factors of the foaming effect are determined based on the convolutional neural network to determine the root cause of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com