Conveying system and method capable of adjusting blanking speed at constant speed for steel shell concrete

A technology of constant speed regulation and conveying system, applied in underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of incomplete self-compacting concrete exhaust, unstable steel shell concrete pouring rate, etc., to reduce quality risks , Overcome the air can not be excluded, improve work efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

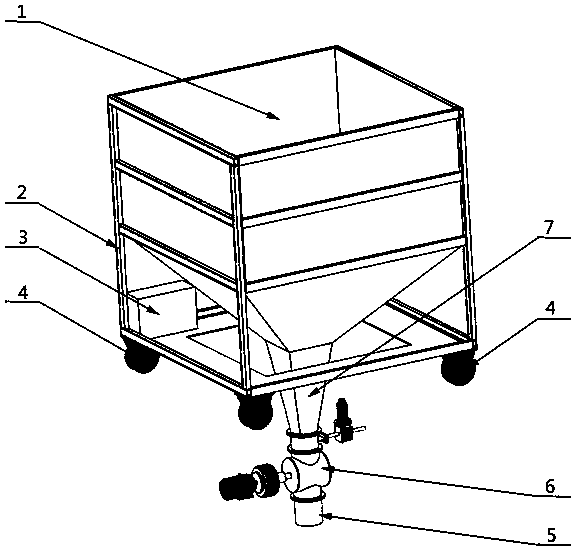

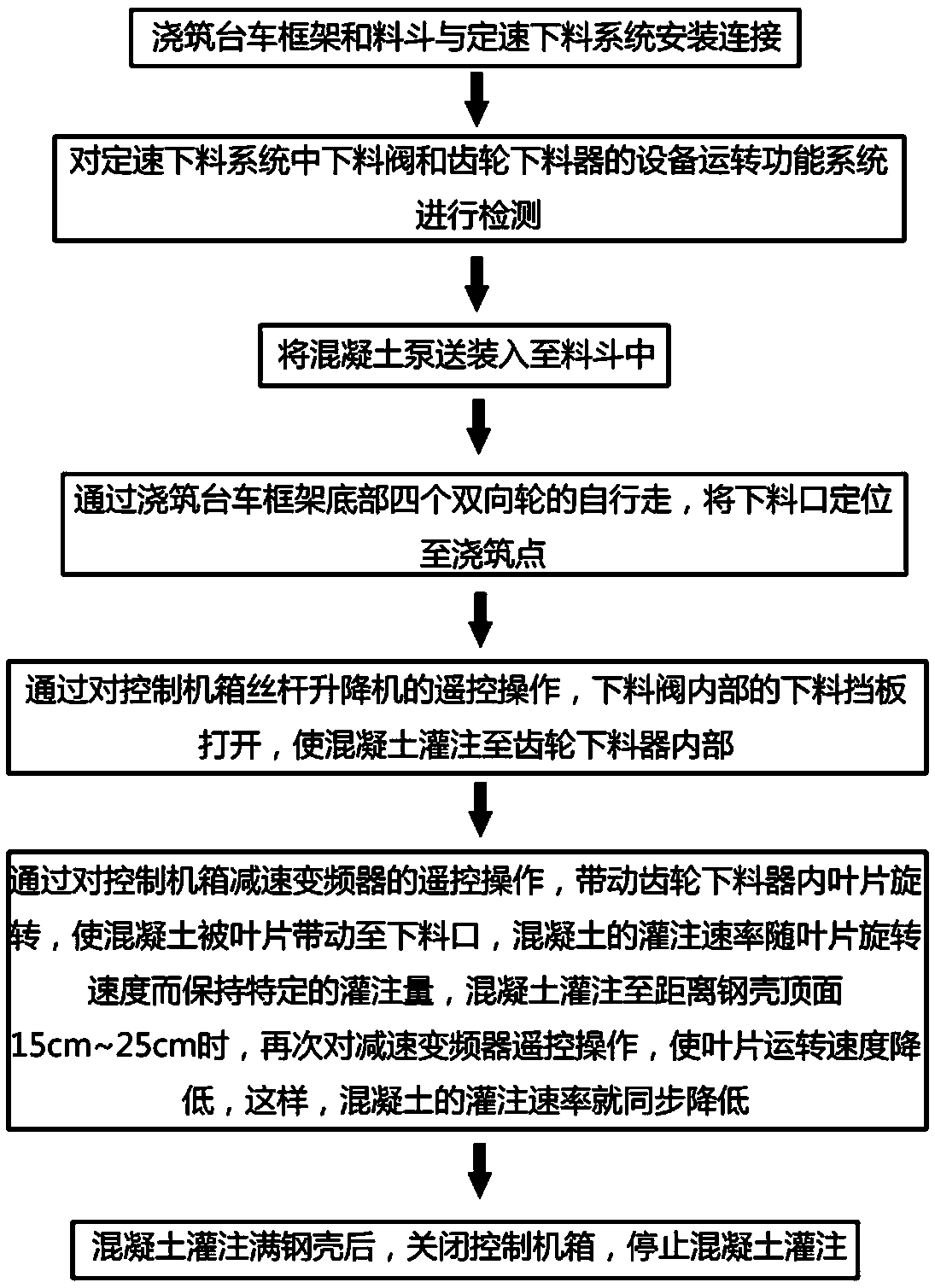

[0039] refer to Figure 1~Figure 3 As shown, the steel shell concrete in an embodiment of the present invention can adjust the feeding speed conveying system and method, including the pouring trolley frame 2, the hopper 1, the constant speed feeding system 6, the hopper 1 is fixed on the pouring On the frame 2 of the trolley, the constant-speed unloading system 6 is connected to the discharge port 5 of the hopper.

[0040] Wherein, the pouring trolley frame 2 includes a control box 3 and two-way wheels 4, the control box 2 is arranged on the trolley frame 2, and four two-way wheels 4 are arranged at the bottom.

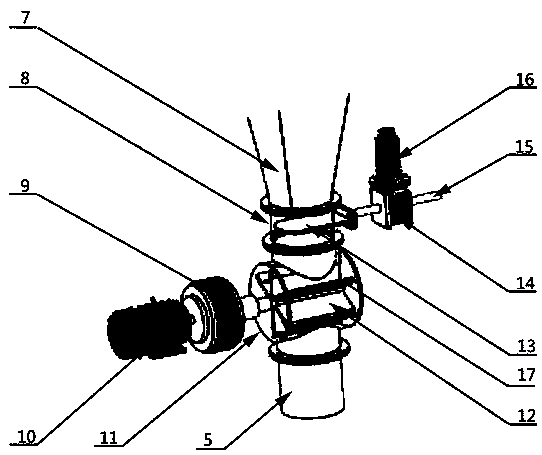

[0041] The constant speed blanking system 6 is composed of a blanking valve 8, a gear blanking device 11, a deceleration frequency converter 9, a screw lift 14 and two motors. The internal structure of the blanking valve 8 includes a blankin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com