Preparation method of PI substrate and display device thereof

A technology for substrates and glass substrates, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. It can solve the problems of bubble formation in the film layer, inability to stabilize the bubble control of the PI film layer, and bubble generation in the film layer, etc., to achieve good discharge bubble effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A method for preparing a PI substrate and a technical solution of a display device thereof according to the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

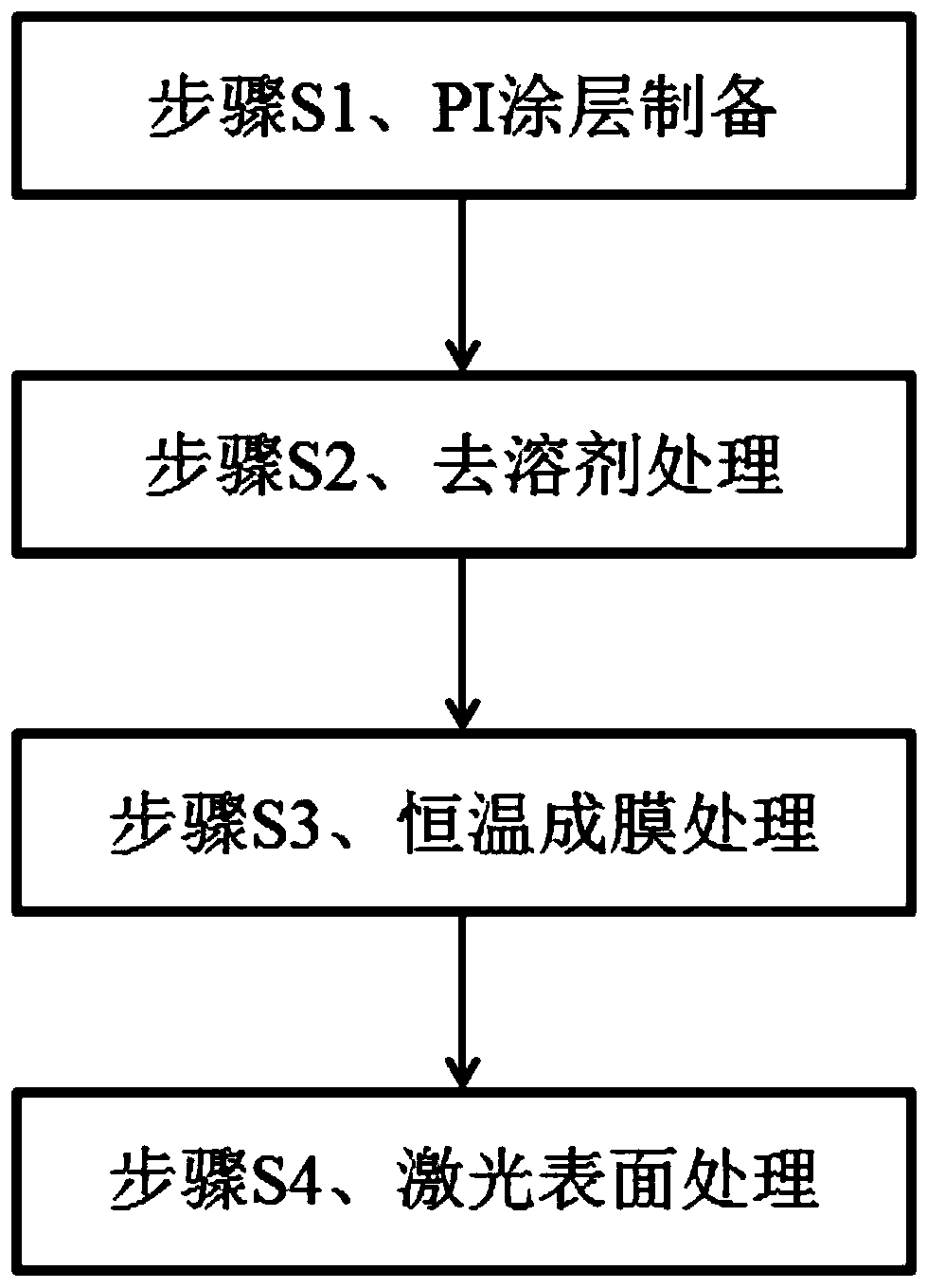

[0044] see figure 1As shown, one embodiment of the present invention provides a method for preparing a PI substrate, which includes a PI coating preparation step S1, a solvent removal treatment step S2, a constant temperature film formation treatment step S3, and a laser treatment surface step S4.

[0045] Each step will be described in detail below.

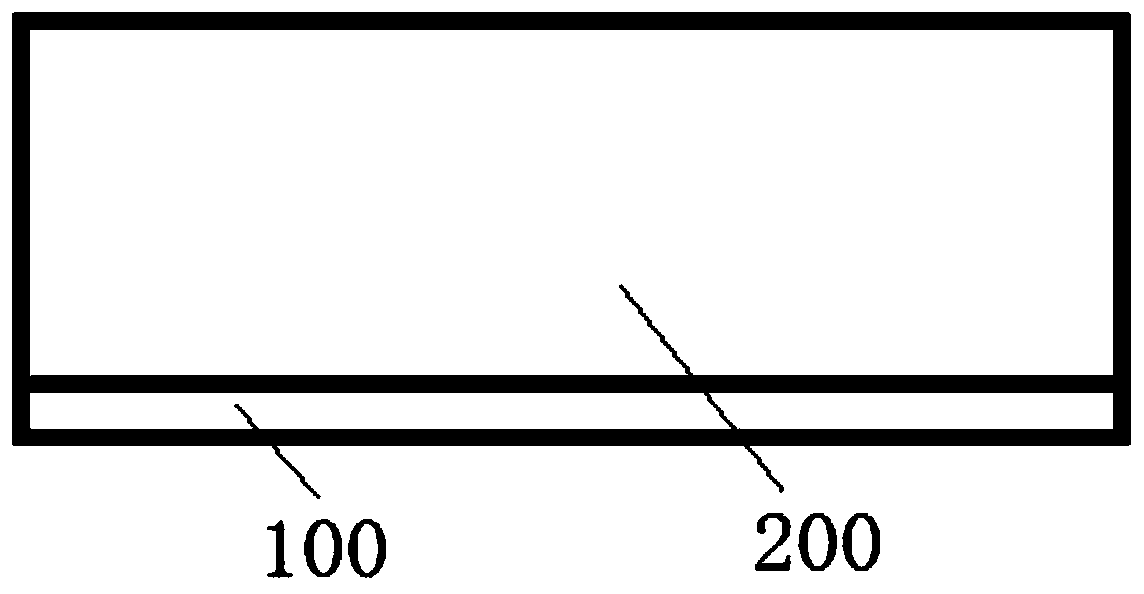

[0046] Step S1, PI coating preparation, which is to provide a glass substrate, and coat a layer of PI material solution on the glass substrate to form a PI coating on the surface of the substrate. The glass substrate used therein is generally, but not limited to, a silicon glass substrate. The PI material solution involved in use is also various PI materials known in the industry that can be used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com