Water-based environmental protection rust inhibitor for steel parts, and preparation method and application of water-based environmental protection rust inhibitor

A rust inhibitor, a technology for steel parts, applied in the field of water-based environmental protection rust inhibitor and metal rust prevention, it can solve the problems of gloss and mechanical property damage, resource waste, product scrap, etc., to enhance stability and service life, improve Adhesion, the effect of enhancing anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

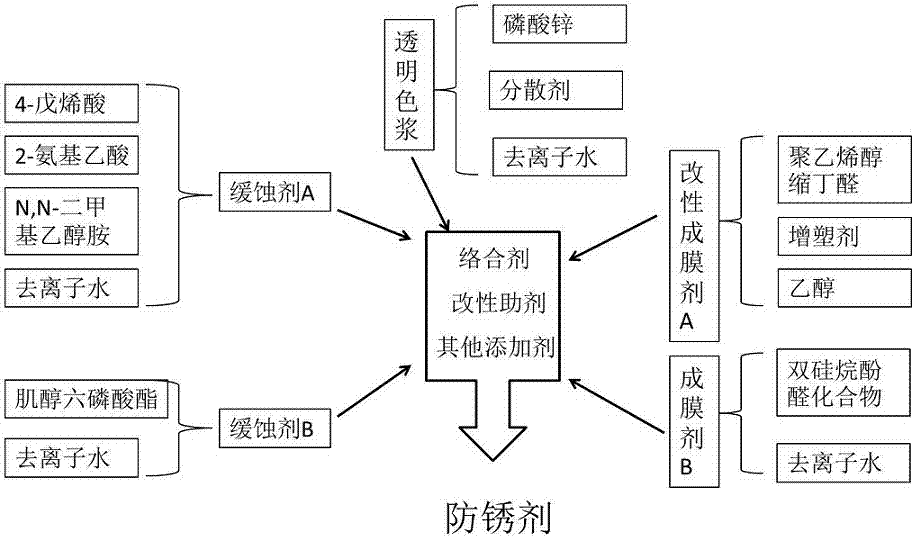

Image

Examples

Embodiment 1

[0046] First, surface pretreatment-rust removal treatment-washing-hydrogen removal treatment-natural cooling treatment is carried out on the rusted steel parts in advance. For chemical rust removal, the rust remover is:

[0047] Inorganic mixed acid, 25wt.% The mass ratio is 4:1 mixed acid of hydrochloric acid and nitric acid

[0048] Organic acid, 5wt.% sulfinic acid

[0049] Zwitterionic Surfactant, 2 wt.% Cocamidopropyl Betaine

[0050] Complexing agent, 7 wt.% Potassium thiocyanate

[0051] Corrosion inhibitor, 2wt.% mercaptobenzothiazole

[0052] Penetrant, 2wt.% Isodecanol Ethoxylates

[0053] Additional salt, 5 wt.% ammonium fluoride

[0054] Additional additives, 0.7 wt.% polyoxyethylene polyoxypropanolamine ether and polyoxyethylene sorbitan fatty acid esters;

[0055] The remainder is a solvent composed of ethanol or ethylene glycol and deionized in a volume ratio of 3:1.

[0056] Then, put 4-pentenoic acid, 2-aminoacetic acid and N,N-dimethylethanolamine in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com