Spray belt bag

A technology of spraying belt bags and nozzles, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve problems such as defects, air pockets, amorphous alloy strip surface, and easy oxidation, so as to improve toughness and reduce air bubbles Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

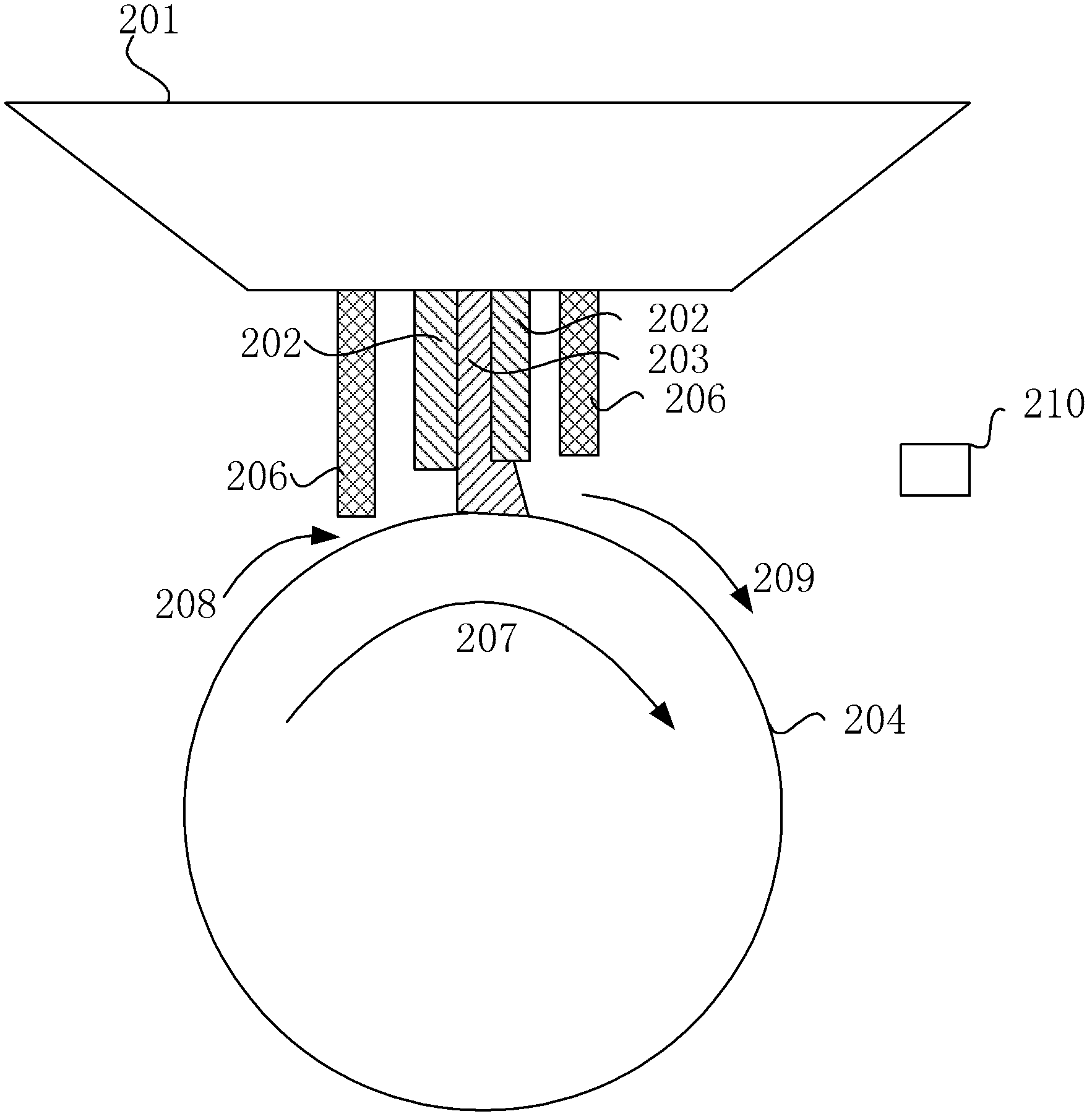

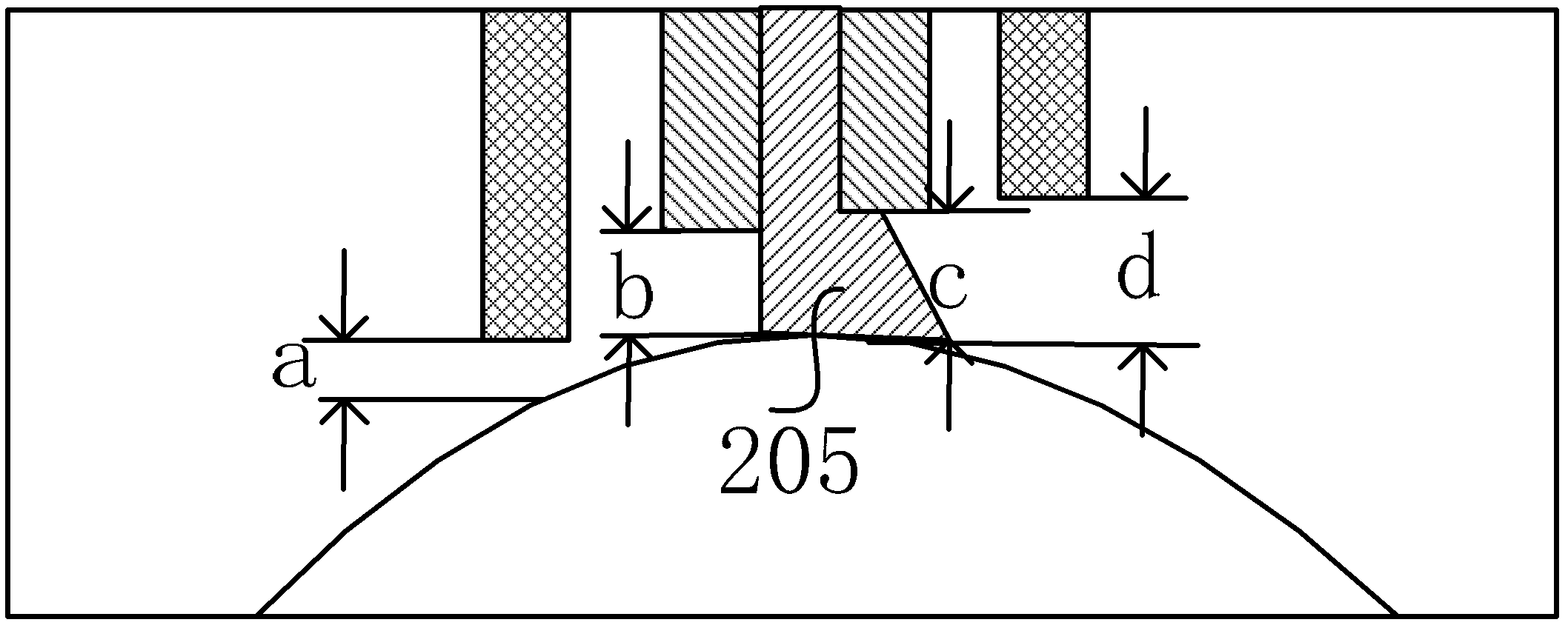

[0012] figure 2 It is a sectional view of the spray tape bag of the embodiment of the present invention, image 3 It is a partially enlarged view of the section view of the spray tape bag of the embodiment of the present invention, as figure 2 , image 3 As shown, there is a nozzle 202 at the bottom of the spray bag 201, and the molten metal 203 is sprayed from the nozzle 202 onto the crystallization roller 204, and the crystallization roller 204 rotates clockwise, and the molten metal 203 forms an amorphous alloy strip through rapid cooling, and the nozzle 202 The molten metal 203 between the crystallization roll 204 is called a molten pool 205 . When the molten pool 205 is directly exposed to the air, it is easy to generate bubbles on the contact surface with the crystallization roller 204, thereby causing defec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com