Method for preparing sustained-release coating material with organic silicon

A slow-release package and film material technology, which is applied in the field of non-metallic materials to shorten the process time, reduce the number of bubbles, and improve the slow-release effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

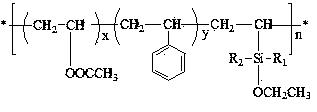

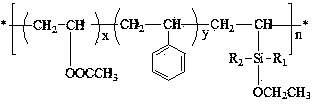

[0023] Sodium carboxymethyl cellulose is made into 100 grams of an aqueous solution with a mass ratio concentration of 0.5%, and a terpolymer of styrene-vinyl acetate-vinyl triethoxysilane with a number average molecular weight of 50,000 is made into 8.0 grams The aqueous solution with a mass ratio concentration of 5% is kept warm at 80°C for subsequent use; 50 grams of gelatin is made into an aqueous solution with a mass ratio concentration of 10%, and is incubated at 60°C for subsequent use.

[0024] Mix the above-mentioned gelatin aqueous solution, sodium carboxymethylcellulose aqueous solution and styrene-vinyl acetate-vinyl triethoxysilane terpolymer aqueous solution together, add 12.5 grams of fatty alcohol polyoxyethylene ether, and use 500rpm Disperse at a stirring speed of 60 minutes to obtain an O / W emulsion, add 3 ml of 40% glutaraldehyde aqueous solution to the above system, continue stirring for 90 minutes, add 15% acetic acid solution to adjust the pH value of the...

Embodiment 2

[0026] Make 100 grams of sodium carboxymethyl cellulose into an aqueous solution with a concentration of 10% by mass, and make a terpolymer of styrene-vinyl acetate-vinyldimethylethoxysilane with a number average molecular weight of 25,000 100 grams of the aqueous solution with a mass ratio concentration of 10% are kept at 90°C for subsequent use; gelatin is made into 100 grams of the aqueous solution with a mass ratio concentration of 5%, and are incubated at 50°C for subsequent use.

[0027] Mix the above-mentioned gelatin aqueous solution, sodium carboxymethylcellulose aqueous solution and styrene-vinyl acetate-vinyl dimethylethoxysilane terpolymer aqueous solution together, add 75.0 grams of nonylphenol polyoxyethylene ether, Disperse at a stirring speed of 1000rpm for 100 minutes to obtain an O / W emulsion, add 5 ml of 25% acetaldehyde aqueous solution to the above system, continue stirring for 60 minutes, add 5% sulfuric acid solution to adjust the pH value of the system t...

Embodiment 3

[0029] Make 100 grams of sodium carboxymethyl cellulose into an aqueous solution with a concentration of 2% in mass ratio, and make a terpolymer of styrene-vinyl acetate-vinyldiphenylethoxysilane with a number average molecular weight of 250,000 9.6 grams of the aqueous solution with a mass ratio concentration of 3% are kept warm at 60°C for subsequent use; gelatin is made into 40 grams of a mass ratio concentration of 5% aqueous solution, and are incubated at 70°C for subsequent use.

[0030] Mix the above-mentioned gelatin aqueous solution, sodium carboxymethylcellulose aqueous solution and styrene-vinyl acetate-vinyl diphenylethoxysilane terpolymer aqueous solution together, add 2.8 grams of pentaerythritol ester, and stir at 1200rpm Disperse for 120 minutes to prepare an O / W emulsion, add 2.5 ml of 37% formaldehyde solution to the above system, continue stirring for 30 minutes, add 5% tartaric acid solution to adjust the pH value of the system to 7.3, and filter to obtain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com