Semi-flexible circuit board and preparation method thereof

A semi-flexible, circuit board technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problem of easy glue overflow in semi-flexible areas, achieve good toughness, reduce the degree of glue overflow, and solve the problem of overflow glue problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

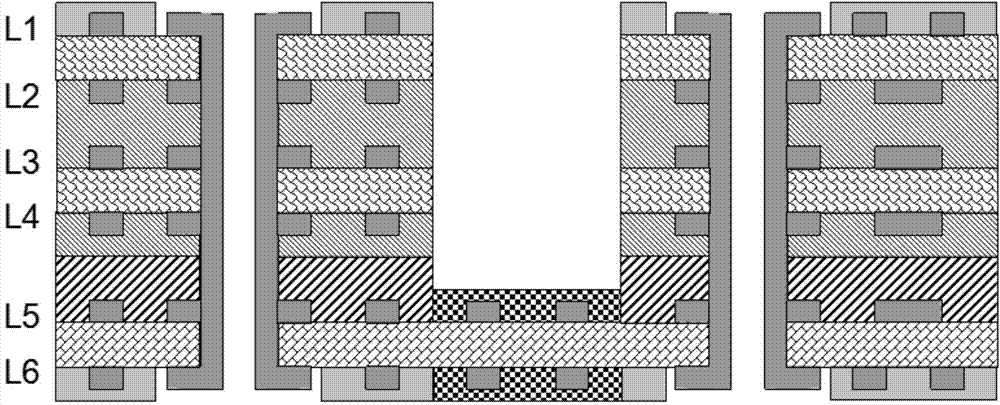

[0041] A semi-flexible circuit board with a total of 6 layers, of which the L5-6 layer is a semi-flexible layer, and the remaining layers are rigid layers. The structure is as follows figure 1 shown. The preparation method of this circuit board is as follows:

[0042] 1. Rigid sub-board production.

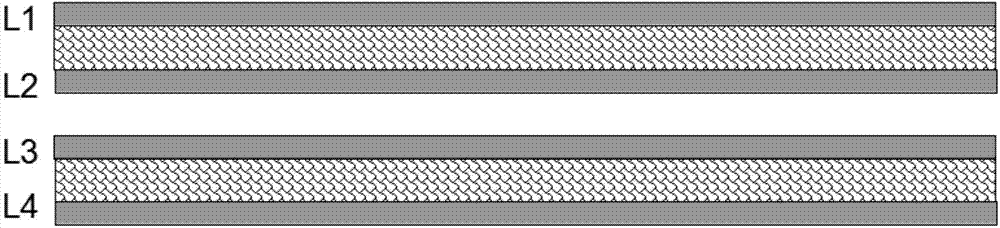

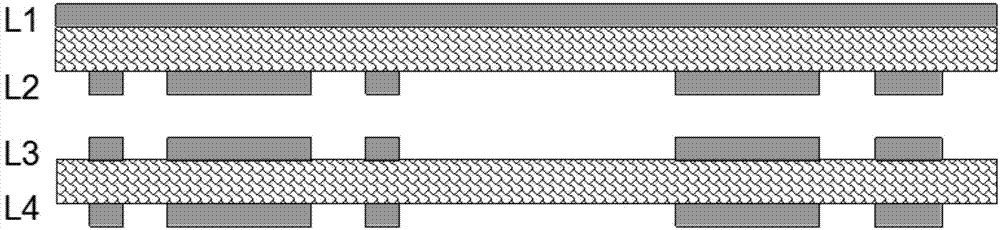

[0043] (1) The inner layer circuit of the rigid core board: through the method of film or laser imaging and acid etching figure 2 On the rigid core board shown, the inner layer circuit patterns of the designed inner layers L2, L3, and L4 are transferred and produced, as shown in image 3 shown.

[0044] (2) Lamination of rigid sub-boards: The above two rigid core boards are pressed together with a flowable prepreg to form a L1-4 rigid sub-board. ) needs to be pressed with prepreg and temporary copper foil.

[0045] Among them: the thickness of the prepreg after lamination is reduced by 50-100 μm for the thickness of the medium between the circuit layer and the semi-flexible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com