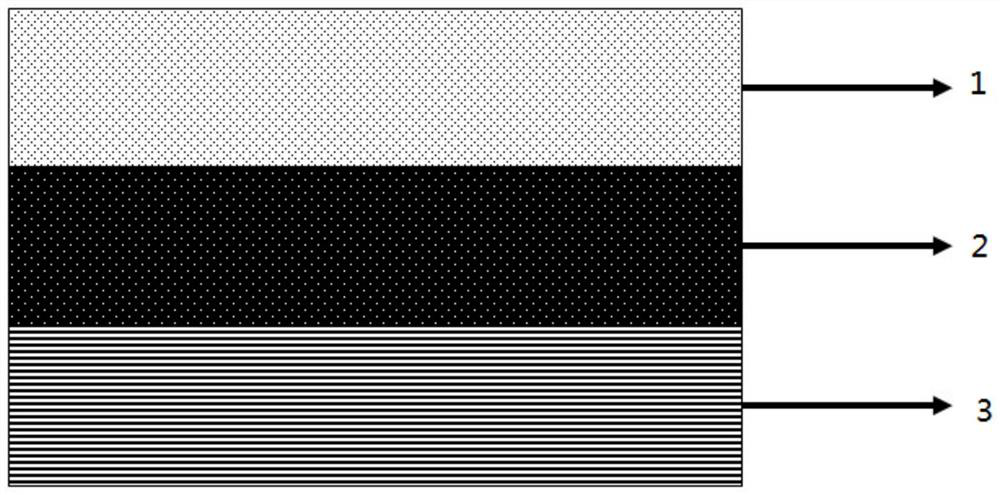

Fluorocarbon coating, preparation method thereof and multilayer film application

A technology of fluorocarbon coatings and coatings, which is applied in the field of coatings, and can solve the problems of low elongation at break of paint films or coatings, poor tensile properties and high ductility, poor adhesion between coatings and plastic substrates, etc. problem, to achieve the effect of improving adhesion, reducing swelling, and ensuring interlayer bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

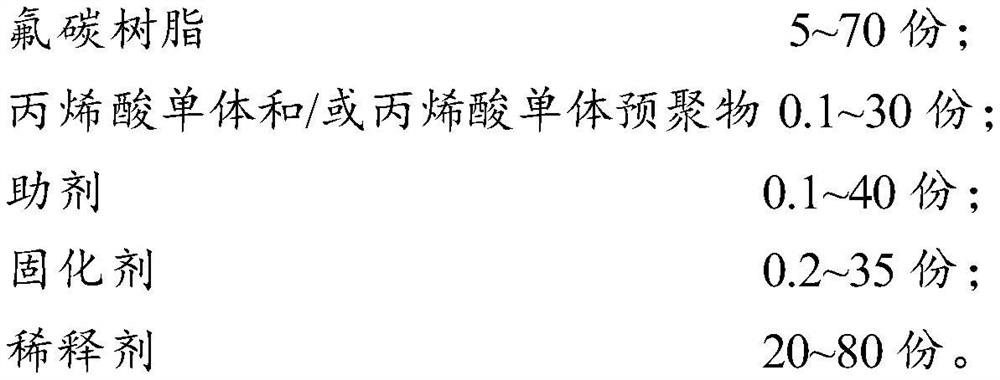

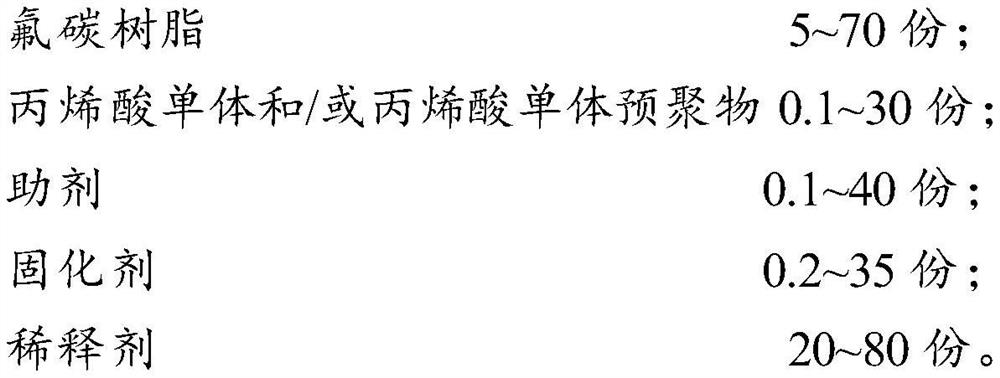

[0071] The present invention provides the preparation method of the fluorocarbon coating described in any one of the above technical solutions, comprising:

[0072] A) fluorocarbon resin and diluent are mixed to obtain the first mixture;

[0073] B) mixing acrylic monomer and / or acrylic monomer prepolymer, diluent, auxiliary agent and the first mixture, stirring and reacting to obtain the second mixture;

[0074] C) The second mixture, diluent, auxiliary agent and curing agent are stirred and mixed to obtain.

[0075] The preparation method of the fluorocarbon coating according to any one of the above technical solutions provided by the present invention firstly mixes the fluorocarbon resin and the diluent to obtain a first mixture.

[0076] Preferably, the fluorocarbon resin and the first diluent are sequentially added for reaction to obtain the first mixture. The reaction is preferably carried out in a reaction kettle.

[0077] The acrylic monomer and / or the acrylic monom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com