Composite material, preparation method and application thereof

A composite material and sheet technology, applied in the field of composite materials, can solve the problems of high mold temperature, poor surface quality, high energy consumption, etc., and achieve the effects of high interlayer bonding strength, good surface quality, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the composite material provided by the present invention comprises attaching a fiber layer on at least one side surface of a thermoplastic sheet or a metal sheet through an adhesive to form a preform, and then forming a preform on the surface of the fiber layer of the preform A two-component polyurethane resin is used for resin transfer molding to form a polyurethane-fiber layer together with the fiber layer; the two-component polyurethane resin contains a polyol component and a polyisocyanate component. In the present invention, the polyurethane-fiber layer refers to a coating comprising a fiber layer formed after the two-component polyurethane resin permeates into the fiber layer and is solidified, that is, the coating on the surface of the thermoplastic sheet is composed of a fiber layer and a two-component polyurethane resin. The overall structure formed by curing.

[0014] The material of the thermoplastic sheet is not particularly limited...

Embodiment approach

[0021] According to a preferred embodiment of the present invention, the viscosity of the polyol component at 25°C is less than 2500mPa·s, more preferably less than 2000mPa·s, most preferably less than 1500mPa·s; the viscosity of the polyisocyanate component at 25°C The viscosity at lower temperature is less than 2000mPa·s, more preferably less than 1500mPa·s, most preferably less than 1000mPa·s. The inventors of the present invention have found that when the viscosity of the polyol component and the polyisocyanate component is controlled within the above-mentioned preferred range, the mixing efficiency of the polyol component and the polyisocyanate component and the effect on the fiber layer can be improved. infiltration.

[0022] According to the present invention, the two-component polyurethane resin further contains a catalyst for catalyzing the reaction between the polyol component and the polyisocyanate component. The catalyst may be selected from at least one of organi...

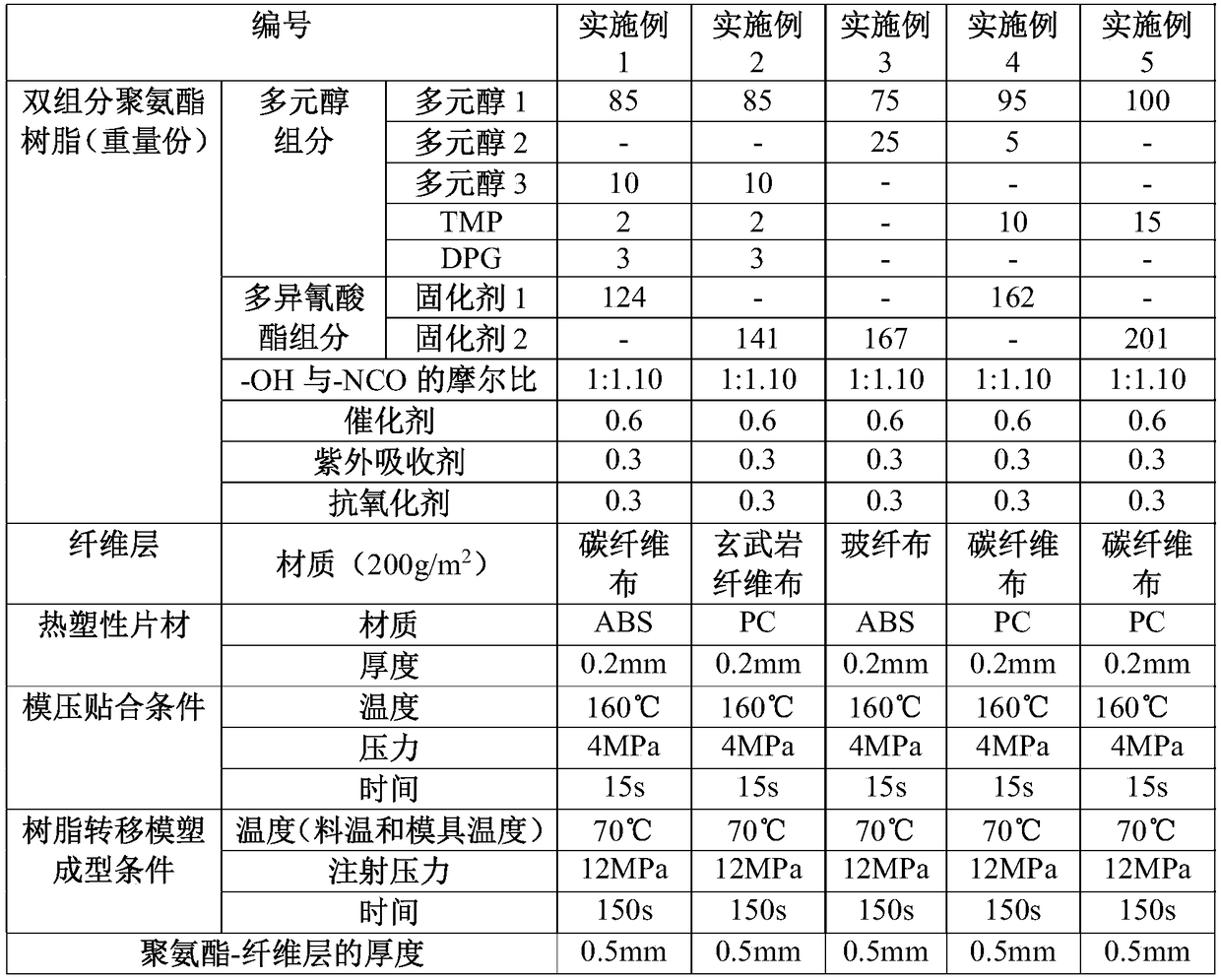

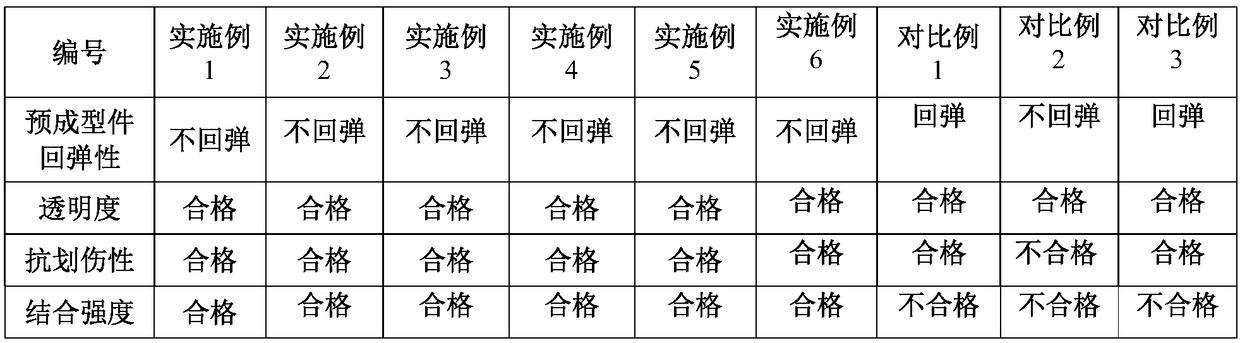

Embodiment 1-5

[0046] A polyurethane hot-melt adhesive film (purchased from Shanghai Hehe Hot-melt Adhesive Co., Ltd., brand LN376) is thermally pasted on one side of the fiber layer, and then the thermoplastic sheet is put into a pre-forming mold, and then put into A fiber layer with a polyurethane-type hot-melt adhesive film attached (placed in such a way that the polyurethane-type hot-melt adhesive film is placed between the thermoplastic sheet and the fiber layer), followed by molding so that the fiber layer is attached to one side of the thermoplastic sheet On the surface, a preform is formed. Among them, the specific types and thicknesses of the fiber layer and the thermoplastic sheet and the conditions for molding and bonding are shown in Table 1.

[0047] The preform is placed in the mold with the fiber layer of the preform facing up, and then a two-component polyurethane resin is injected into the mold with a high-pressure injection machine for resin transfer molding, so as to be co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com