Press felt base fabric exhibiting reduced interference

A technology of base fabric and fabric belt, applied in the direction of fabric, textile, textile and paper making, etc., can solve the problems of uneven water removal and sheet marking, etc., to achieve improved pressure uniformity, long felt life, high porosity volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

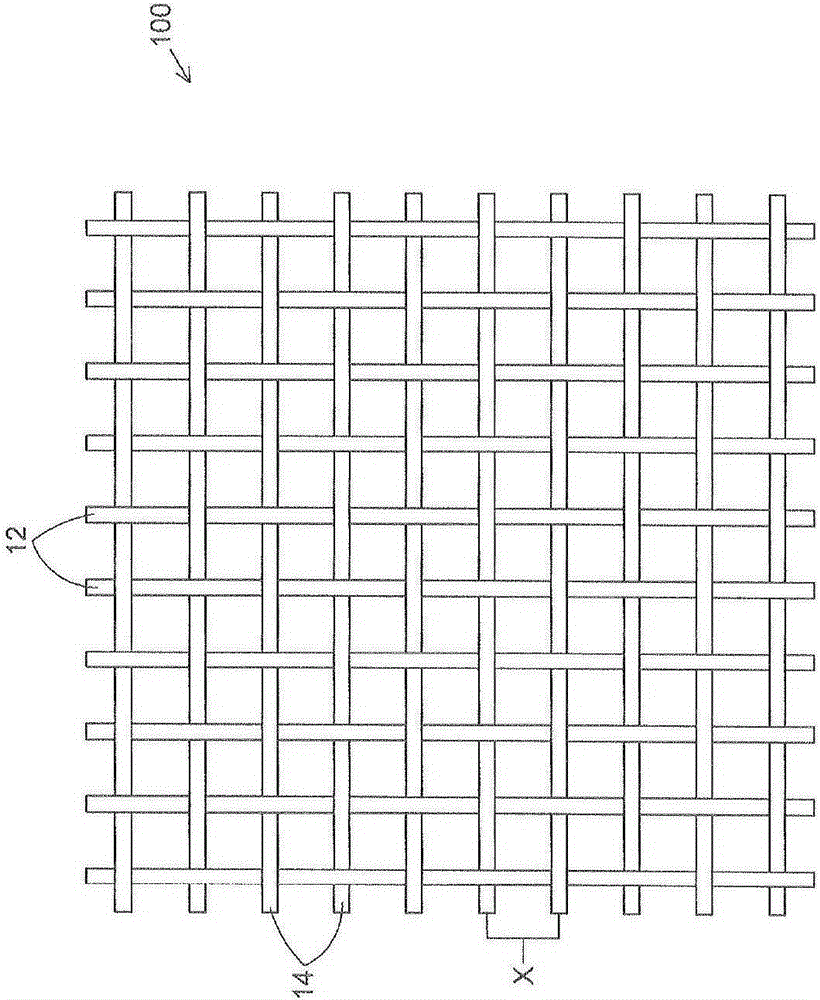

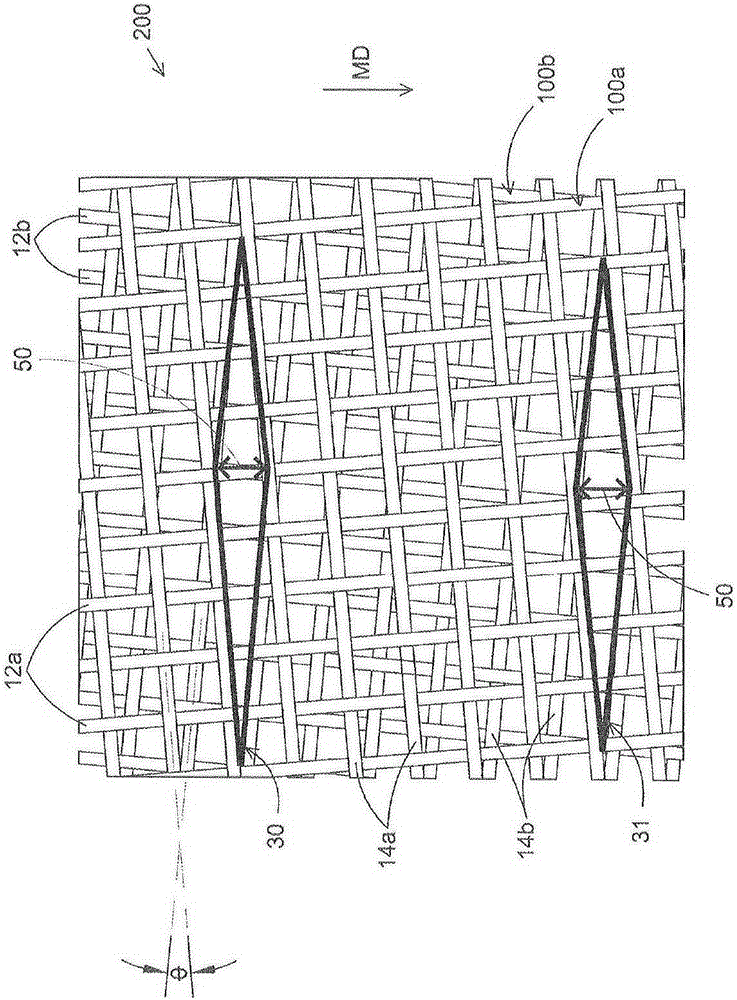

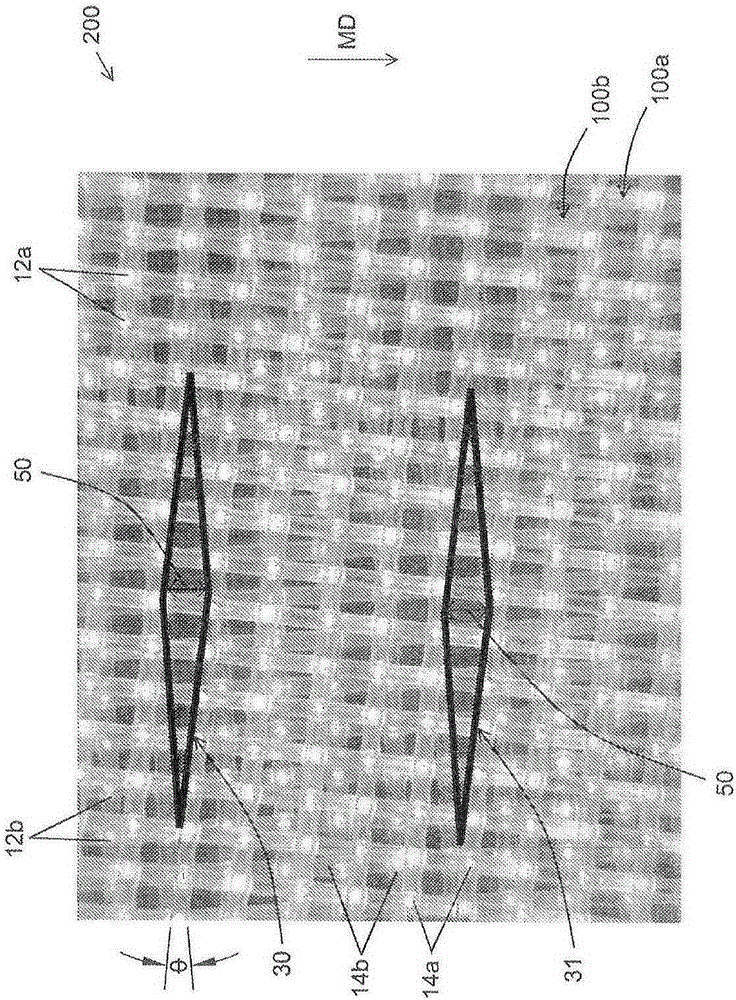

[0074] In the combination of conventional spiral wound press mats (hereinafter referred to as "multiaxial") or flat-woven press felts of double-layer construction (comprising one single layer of fabric suspended inside another layer) (hereinafter referred to as "flat-woven") A base fabric such as 100 in FIG. 1 is woven from a single monofilament fiber warp yarn 12 and a single monofilament fiber weft yarn 14 according to a flat weave as shown or other desired pattern as applicable for the intended end use. In multiaxial fabrics, the base fabric 100 is helically wound as a narrow strip to provide the length and width of the final fabric required to form a tubular sock-like structure, which is flattened on itself to form two stacked layers; , the two layers of base fabric 100 are respectively woven into required width and length, and then one of them is inserted into the other. In FIG. 1, distance X represents the regular yarn-to-yarn spacing of single monofilament fiber weft ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com