Operation and sealing method of large cubic press based on two-sided jacking mode

A six-sided top press and two-sided technology, which is applied to the sealing of engines, chemical instruments and methods, and methods for chemically changing substances by using atmospheric pressure. It can solve problems such as the uniformity of stress distribution of the top hammer and the waste of equipment capacity. , to achieve the effect of improving pressure uniformity, improving utilization rate and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

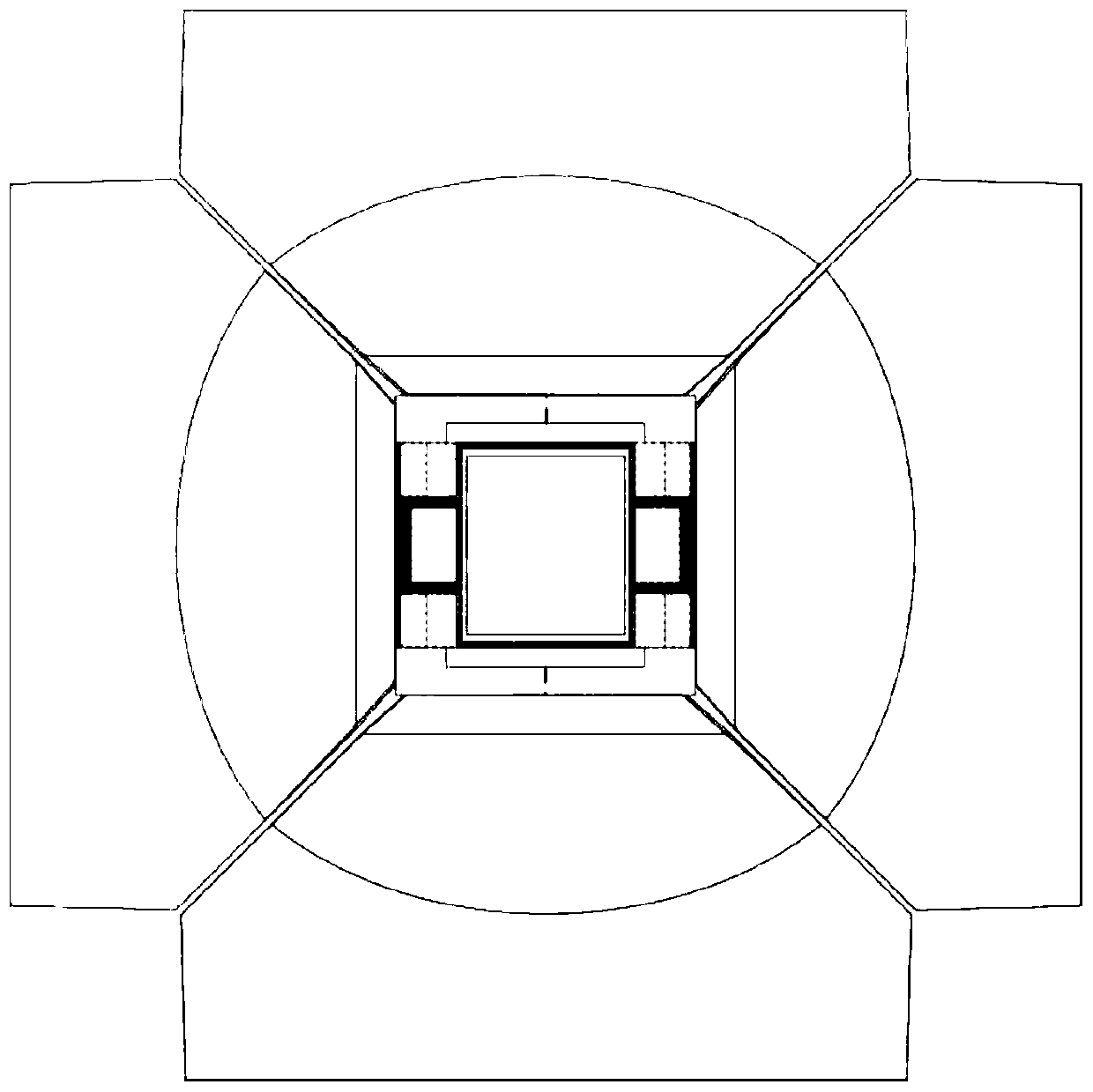

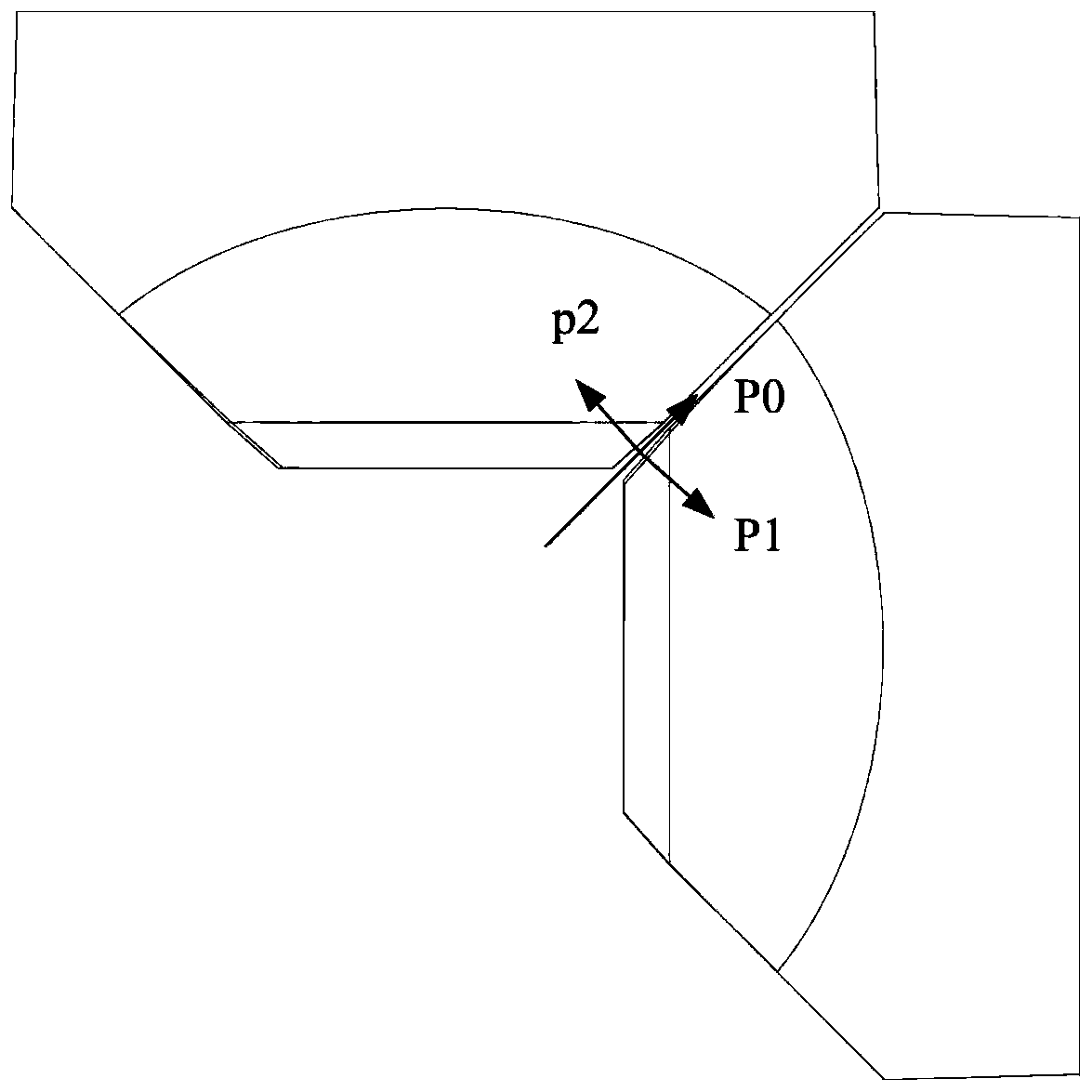

[0043] Example: such as Figure 1 to Figure 9 As shown, the cylinder diameter of the six-sided top press used is 800 mm, and the six top hammers of the six-sided top press include two heating hammers and four non-heating hammers, and the diameter D of the six top hammers is 175 mm.

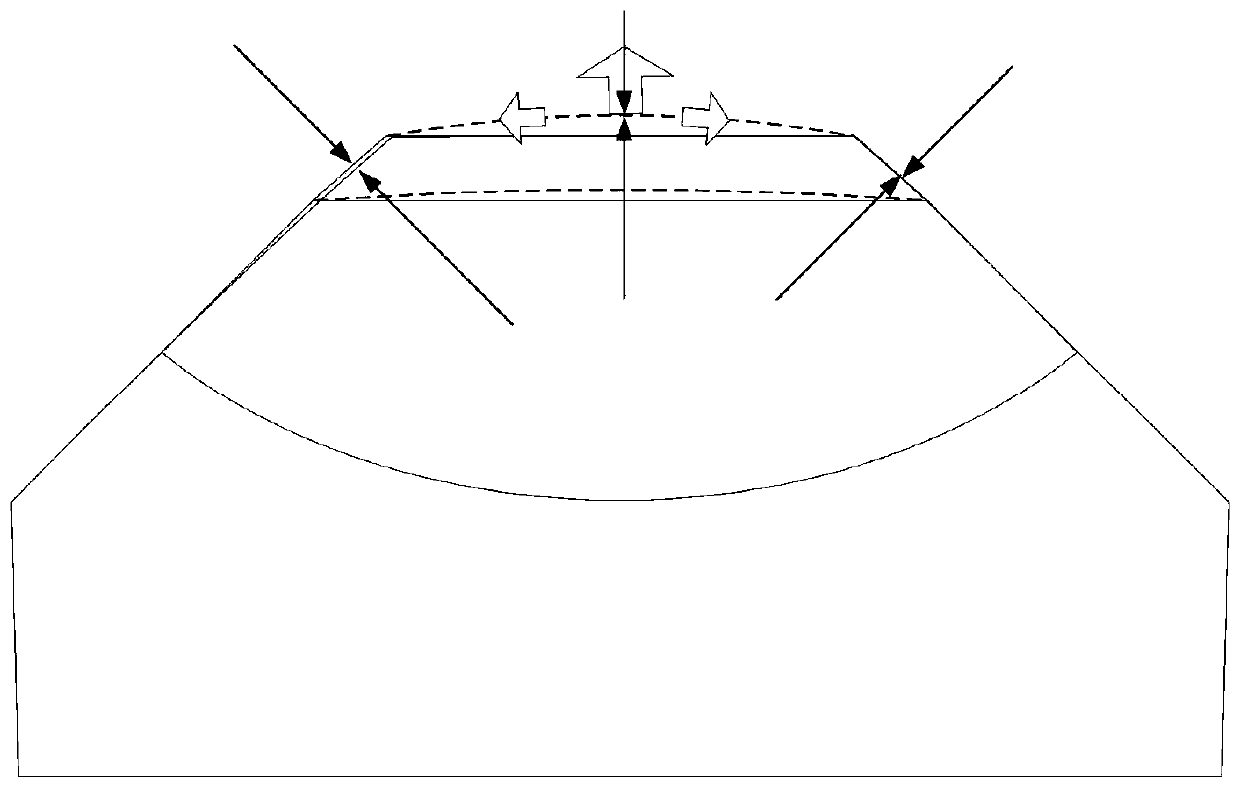

[0044] The dimensions of the four non-heated hammers are: the length L1 of the top surface of the non-heated hammer is 114.0mm, and the width W1 of the top surface is 68.0mm; the length L2 of the small hypotenuse of the non-heated hammer is 102.0mm, and the width W2 of the small hypotenuse is 9.0mm ;Paste a piece of polymer film on the top surface of the non-heating hammer, then use the surface of the slope (including the small bevel) of the non-heating hammer to be roughened by laser, then electroplate a nickel layer with a thickness of 0.80mm, and finally grind it to a large slope The thickness of the nickel layer is 0.5mm. At this time, the small hypotenuse is filled to form four complete large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com