Indirect heating-type synthesis assembly for high-temperature and high-pressure artificial single crystal synthesis by using cubic press

A six-sided top press, high temperature and high pressure technology, applied in the application of ultra-high pressure process, etc., can solve the problems of increased thickness and size of insulation pipes and insulation pipes, expansion stress that easily causes explosion hammer, poor stability of heating elements, etc. , to achieve the effects of being conducive to pressure transmission, reducing the risk of explosion hammer, and excellent high-temperature insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

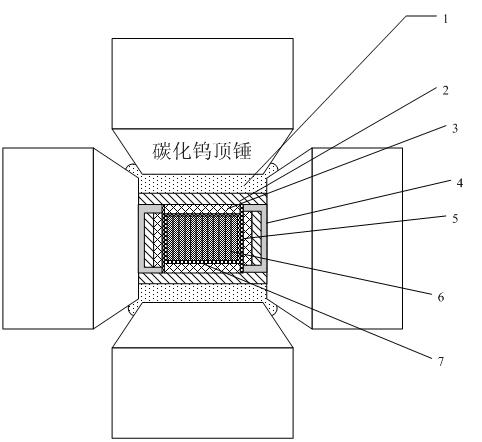

[0051] Synthetic assembly in a six-sided top diamond press with a cavity diameter of 23 mm, including:

[0052] Pyrophyllite powder briquettes, size 38mm 3 ; Lined with dolomite casing, the middle is a cylindrical synthetic cavity with a diameter of 23mm

[0053] Alumina ceramic high temperature protection tube: wall thickness 5mm, outer diameter 23mm, inner diameter 13mm, height 11.6 mm

[0054] Metal cup: metal molybdenum, wall thickness 0.2mm, outer diameter 13mm, height 11.6mm

[0055] High melting point metal conductive sheet: metal molybdenum, thickness 0.2mm, diameter 23mm

[0056] Composite conductive plug: steel shell: thickness 3mm, outer diameter 23mm, height 13mm

[0057] Filling in the steel shell: alumina ceramic disc, diameter 17mm, thickness 5mm

[0058] Dolomite disk: diameter 17mm, thickness 5mm

[0059] Assembled into a synthetic assembly, the metal cup is filled with a synthetic stem.

[0060] The synthesis assembly is placed in a...

Embodiment 2

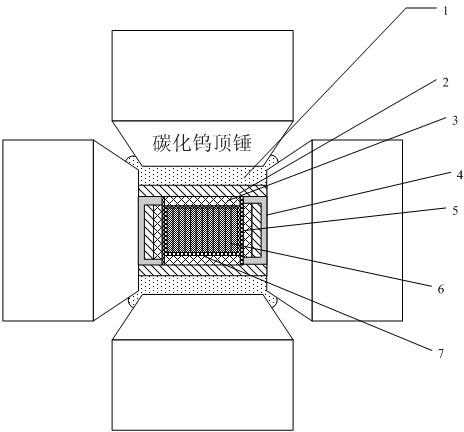

[0066] Synthetic assembly in a six-sided top diamond press with a cavity diameter of 23 mm, including:

[0067] Pyrophyllite powder briquettes, size 38mm 3 ; Lined with dolomite casing, the middle is a cylindrical synthetic cavity with a diameter of 23mm

[0068] Alumina ceramic high temperature protection tube: wall thickness 5mm, outer diameter 23mm, inner diameter 13mm, height 11.6 mm

[0069] Metal cup: metal molybdenum, wall thickness 0.2mm, outer diameter 13mm, height 11.6mm

[0070] High melting point metal conductive sheet: metal molybdenum, thickness 0.2mm, diameter 23mm

[0071] Composite conductive plug: steel shell: thickness 3mm, outer diameter 23mm, height 13mm

[0072] Filling in the steel shell: alumina ceramic disc: diameter 17mm, thickness 5mm

[0073] Dolomite disk: diameter 17mm, thickness 5mm

[0074] Assembled into a synthetic assembly, the metal cup is filled with a synthetic stem.

[0075]The synthesis assembly is placed in a ...

Embodiment 3

[0081] The synthesis assembly was the same as in Example 1, and the synthesis time was extended to 96 hours.

[0082] Synthesis conditions: temperature 1450°C; pressure 52000 atmospheres (estimated by bismuth filament phase transition); synthesis time 96 hours.

[0083] Synthetic core column: The raw materials used are 2.8g of W14 diamond powder and 4 pieces of iron-nickel catalyst sheets; they are packed in metal cups in a stacked manner and densified under a pressure of 200-400MPa.

[0084] The obtained product: a diamond single crystal with a diameter of 1 mm or more: 1.91 grams, with a maximum particle diameter of 3.2 mm.

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com