Composite batten production line

A production line and woodworking technology, which is applied in the direction of wood processing appliances, the joining of wooden veneers, the connecting parts of formwork/template/work frame, etc. Tight bonding and other problems, to achieve the effect of improving tightness, improving processing efficiency, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

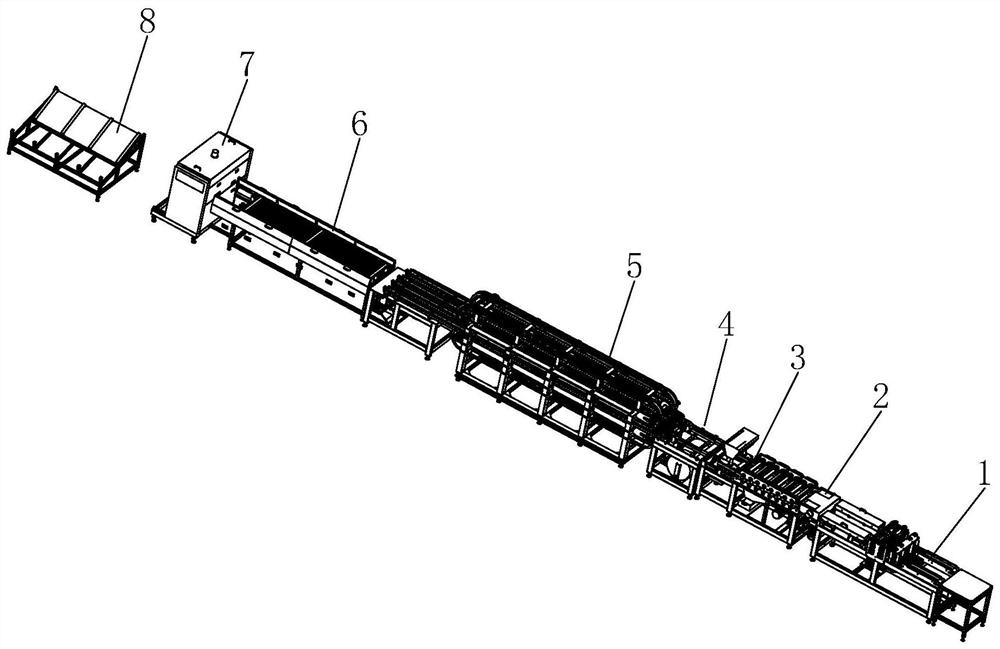

[0045] Example: a composite wood production line, such as figure 1 As shown, it includes a feeding and conveying device 1 for assembling a plurality of wood strips into a wooden body, an online planing device 2 for planing both sides of the wooden body to control the width, and a pressing device for pressing the wooden body. The pressure feeding and gluing device for feeding glue 3. The glass fiber cloth composite device for wrapping the glass fiber cloth on the peripheral side of the wooden body to form a composite wooden square 4. For conveying and gluing the glass fiber cloth on The peripheral side of the wooden block body is provided with a thermoforming device 5 with pressure, a cooling device 6 for conveying the composite wooden block, a cutting device 7 for cutting the composite wooden block, and a lower part for receiving the cut composite wooden block and cutting feed device 8.

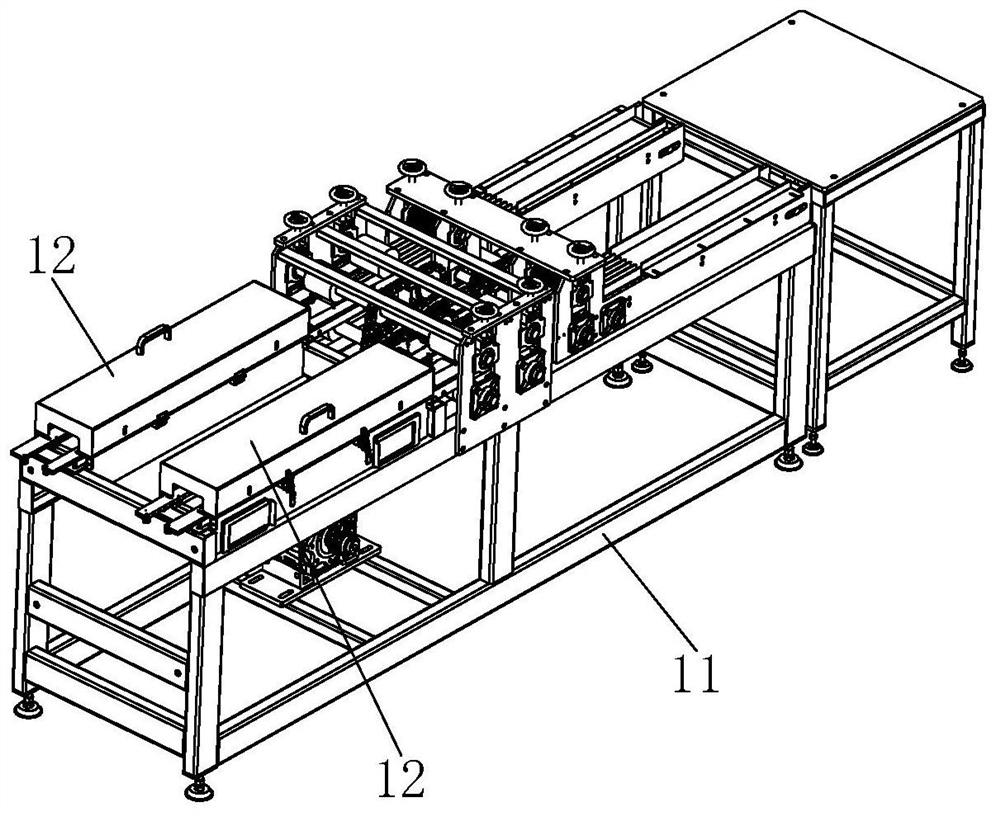

[0046] like figure 1 and figure 2 As shown, the end of the feeding conveyor frame 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com