Method for preparing para aramid paper from para aramid fibrid

A technology of para-aramid paper and para-aramid fiber, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material treatment, fiber dispersant addition, etc., can solve the problem of limited wide application and weak dimensional stability , low elasticity and other problems, to achieve high surface activity, improve green water performance, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

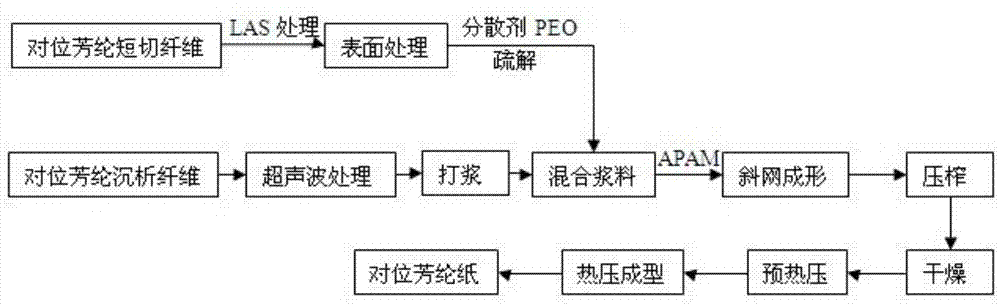

Method used

Image

Examples

Embodiment 1

[0037] The para-aramid precipitated fiber was pretreated for 10 minutes with an ultrasonic processor at a power of 200W and an intermittent time of 5s, and then beating was performed with a trough beater, and the degree of beating was controlled at 35°SR; the aramid chopped fiber was The mass-molar concentration used is 1.5×10 -3 mol / L, the temperature is 40 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 1min under the conditions of pressure 30Pa, power 60W; Add the treated para-aramid chopped fiber and 0.1% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 3:7, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 100°C for 10s, and further hot-presse...

Embodiment 2

[0039] The para-aramid precipitated fiber was pretreated for 15 minutes with an ultrasonic processor at a power of 800W and an intermittent time of 7s, and then beating was performed with a trough beater, and the degree of beating was controlled at 40°SR; the aramid chopped fiber was Utilize a mass-molar concentration of 2.0×10 -3 mol / L, the temperature is 60 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 2min under the conditions of pressure 50Pa, power 70W; Add the treated para-aramid chopped fiber and 0.3% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 5:5, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 120°C for 20s, and further hot press...

Embodiment 3

[0041] The para-aramid precipitated fiber was pretreated for 20 minutes with an ultrasonic processor at a power of 1500W and an intermittent time of 8s, and then was beaten with a trough beater, and the beating degree was controlled at 45°SR; the aramid chopped fiber was used The mass-molar concentration is 2.5×10 -3 mol / L, the temperature is 70 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 3min under the conditions of pressure 70Pa, power 80W; Add the treated para-aramid chopped fiber and 0.7% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 7:3, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 150°C for 30s, and further hot pressed on a hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com