Air bag expansion pressurization method for adhering plastic radial tile faces

A tile surface and plastic technology, which is applied in the processing field of sticky plastic radial sliding bearings, can solve problems such as difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

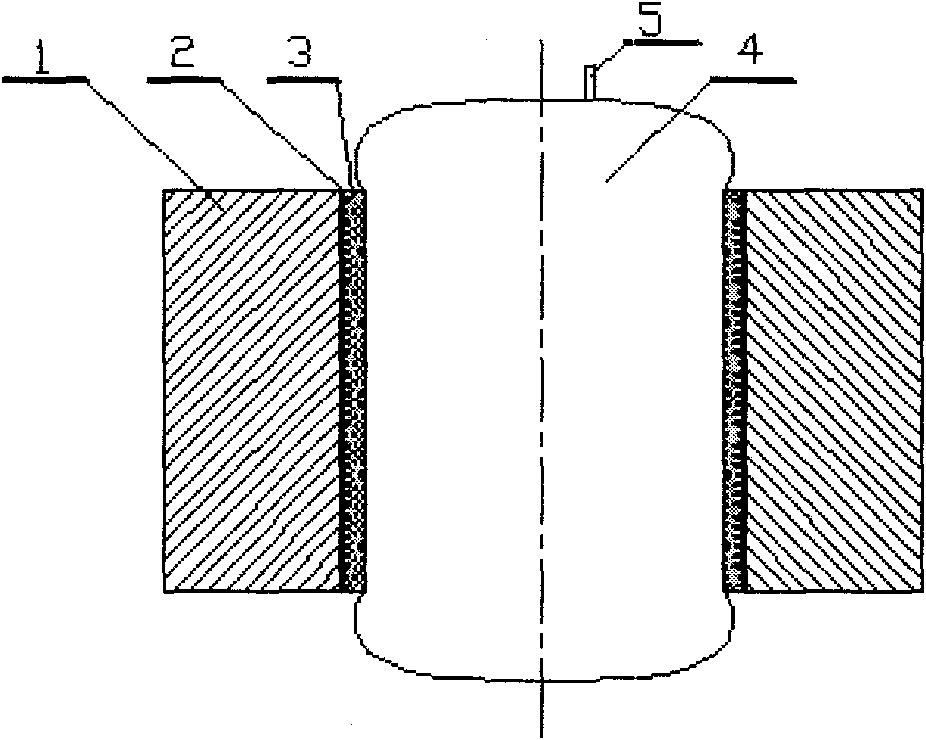

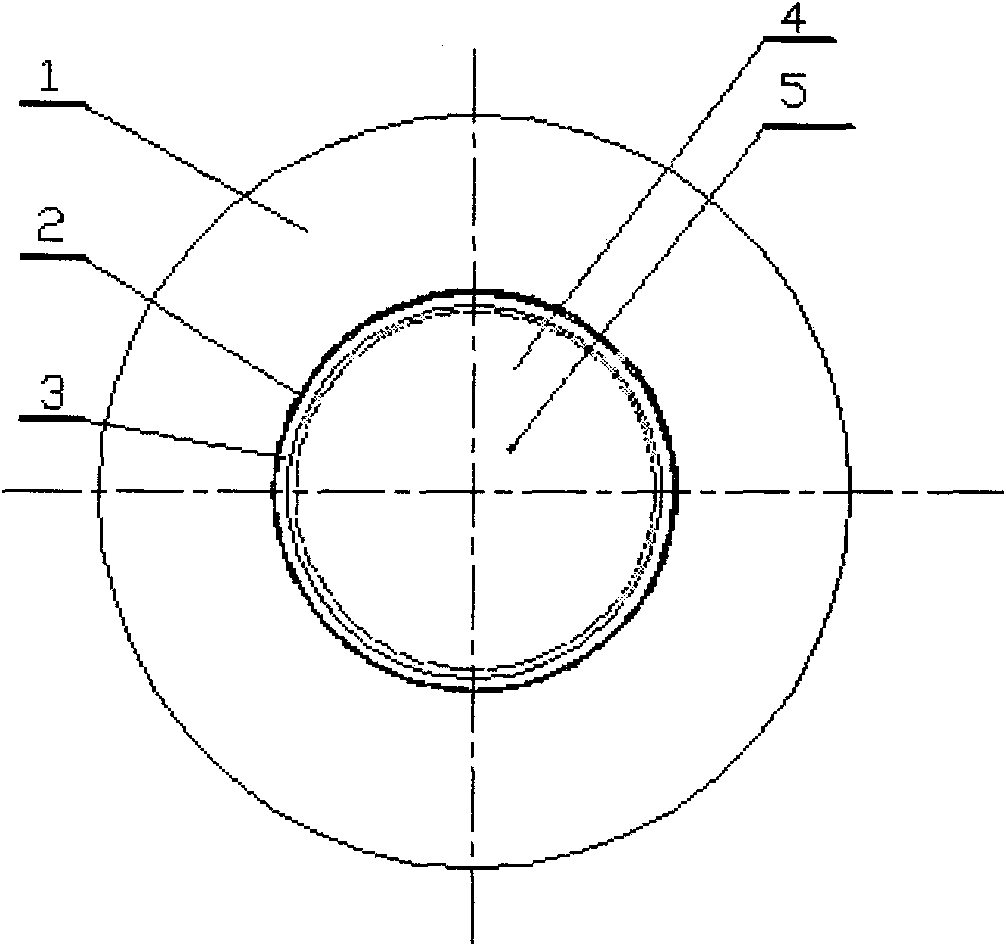

[0004] The technical solution adopted by the present invention to solve the technical problem is: when the inner wall of the radial tile is coated with glue, and the surface of the plastic tile is directly bonded with an adhesive, the air bag is placed in the inner hole of the garden column, and it is inflated to expand around and stick to the tile. surface for uniform pressure.

[0005] The beneficial effect of the present invention is that the structure is simple, and the simple process results in uniform pressure on the tile surface, exerts the advantages in pasting processing, saves investment in equipment and achieves ideal effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com