Processing method of flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate

A processing method and thermoplastic technology, which is applied in the processing field of flat thermoplastic PEKK carbon fiber unidirectional tape laminates, can solve the problems of lack of deformation control structure, poor apparent quality of laminates, insufficient production efficiency, etc., and achieve uniformity of pressure Good, good thickness consistency, the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Process parameters:

[0051] (1) The construction temperature of sealing agent and mold release agent is 20°C;

[0052] (2) The temperature of the upper and lower molds of the flat mold is 370°C;

[0053] (3) Molding holding pressure is 3MPa;

[0054] (4), molding pressure holding time is 5 minutes;

[0055] (5), molding speed is 5cm / min;

[0056] (6), cooling mold opening mold temperature is 140 ℃;

[0057] (7) The pressure relief time is 1s.

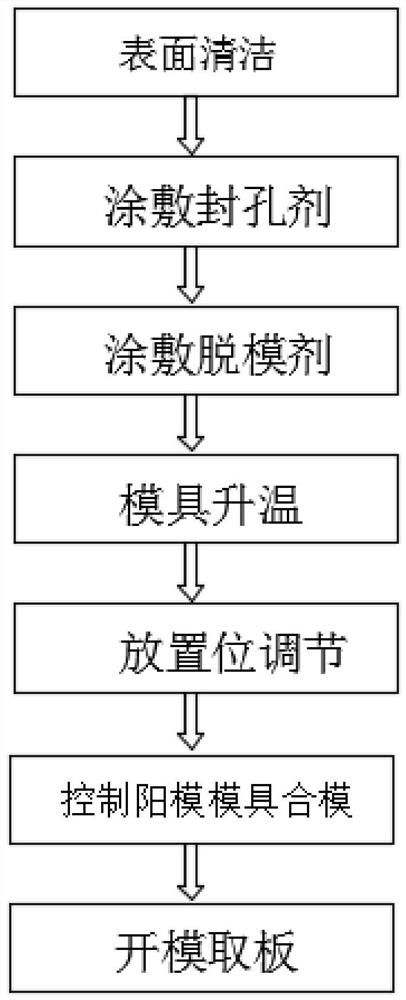

[0058] 2. Processing method:

[0059] (1), the surface of the flat mold is cleaned with acetone solution;

[0060] (2) Apply the sealing agent to ensure the absorption of the sealing agent on the surface of the mold;

[0061] (3) Apply a release agent to ensure that the release agent is absorbed on the surface of the mold;

[0062] (4), the flat mold is heated up to 370-390°C, and kept at a constant temperature for 30-60min;

[0063] (5) The thermoplastic PEKK carbon fiber unidirectional tape laminate is placed at righ...

Embodiment 2

[0075] 1. Process parameters:

[0076] (1) The construction temperature of sealing agent and release agent is 40°C;

[0077] (2) The temperature of the upper and lower molds of the flat mold is 390°C;

[0078] (3) The molding holding pressure is 5MPa;

[0079] (4), molding pressure holding time is 10 minutes;

[0080] (5), molding speed is 10cm / min;

[0081] (6), cooling mold opening mold temperature is 160 ℃;

[0082] (7) The pressure relief time is 2s.

[0083] 2. Processing method:

[0084] (1), the surface of the flat mold is cleaned with acetone solution;

[0085] (2) Apply the sealing agent to ensure the absorption of the sealing agent on the surface of the mold;

[0086] (3) Apply a release agent to ensure that the release agent is absorbed on the surface of the mold;

[0087] (4), the flat mold is heated up to 370-390°C, and kept at a constant temperature for 30-60min;

[0088] (5) The thermoplastic PEKK carbon fiber unidirectional tape laminate is placed at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com