Foliar preparation for improving crop resistance and preparation method thereof

A stress resistance and foliar technology, which is applied to the preparation of the foliar preparations and the field of foliar preparations, can solve the problems of low utilization rate of elements, unstable effects, unbalanced nutrition and the like, so as to improve the cold resistance. The effect of disease resistance, promoting yield improvement and stable fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

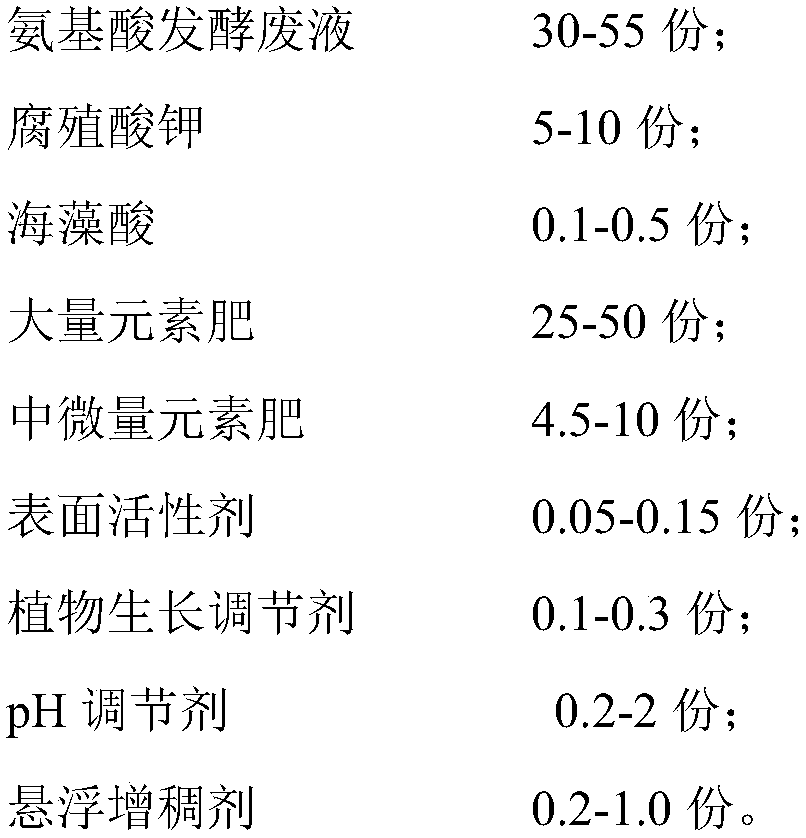

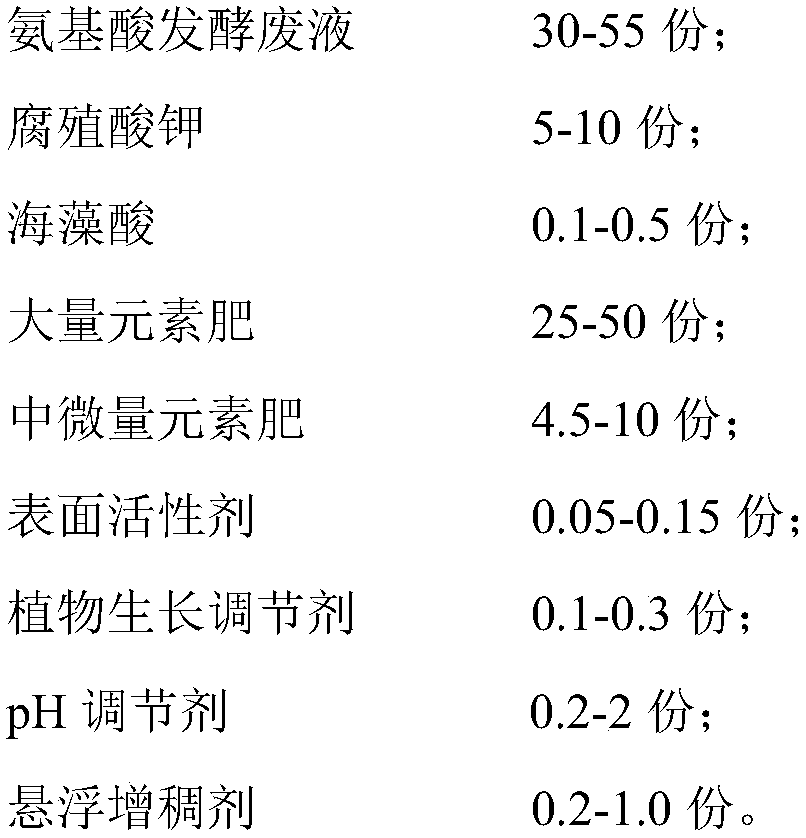

Method used

Image

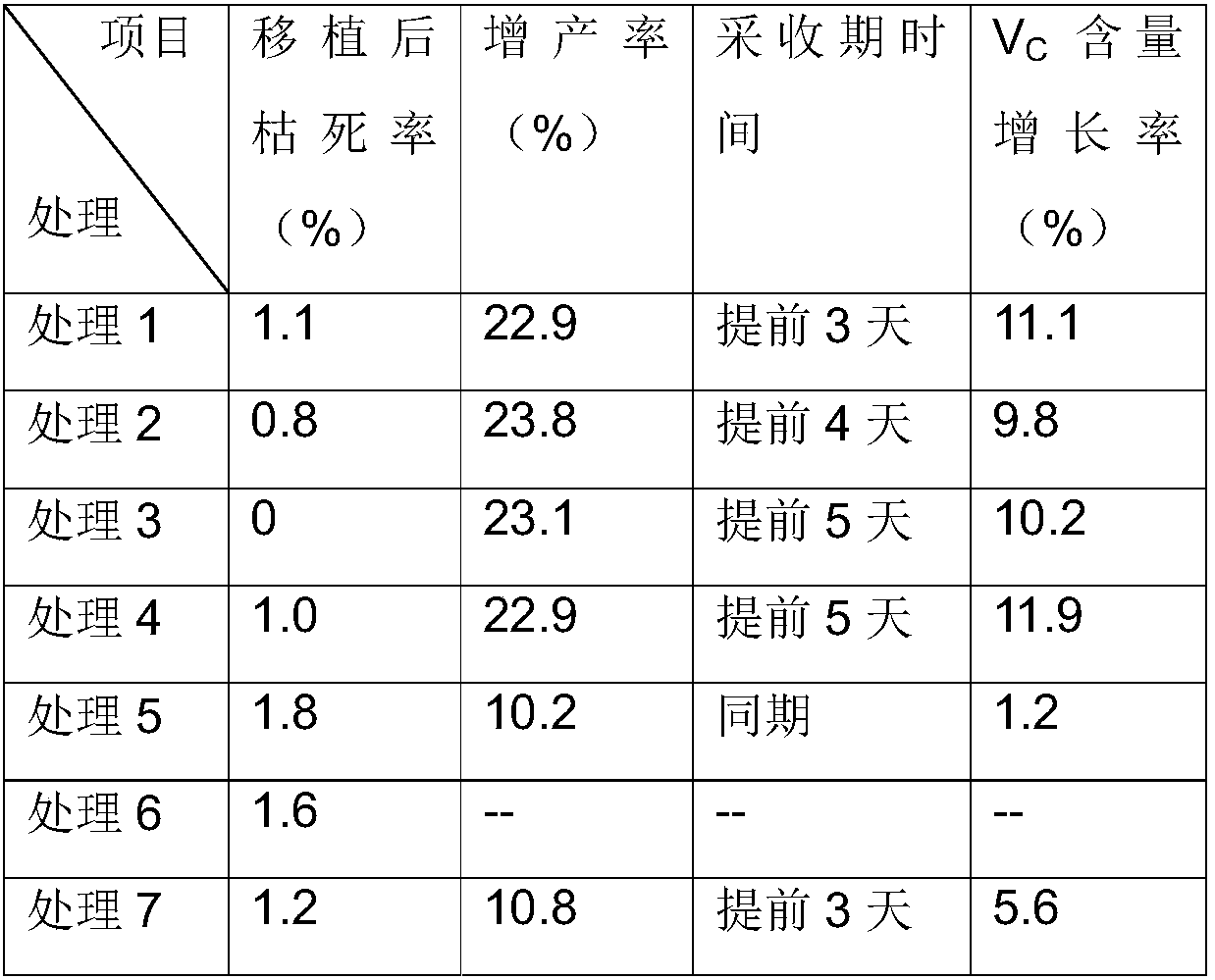

Examples

preparation Embodiment 1

[0045] 30 kg of amino acid fermentation waste liquid (wherein the solid content is 9 kg, and the water-soluble organic matter content is 4.5 kg) is heated to 75 degrees Celsius, and then the pH of the amino acid fermentation waste liquid is adjusted to 6.0 with a mass fraction of 20% sodium hydroxide aqueous solution. Thereafter, 0.5 kg of zinc sulfate, 0.5 kg of ferrous sulfate, 0.5 kg of copper sulfate, 2 kg of borax, and 1 kg of magnesium sulfate were added and stirred for 1.5 hours. Thereafter, 5 kg of urea, 5 kg of ammonium polyphosphate, 10 kg of potassium dihydrogen phosphate, 0.1 kg of alginic acid, 5 kg of potassium humate and 0.2 kg of hydroxypropyl methylcellulose were added to the reaction system, and 0.01 kg of sodium nitrophenolate and surface Active agent Tween-20 0.05kg, then stirred for 2 hours to obtain the foliar preparation of the present invention.

preparation Embodiment 2

[0047] 40 kg of amino acid fermentation waste liquid (wherein the solid content is 15 kg, and the water-soluble organic matter content is 9 kg) is heated to 75 degrees Celsius, and then the pH of the amino acid fermentation waste liquid is adjusted to 6.0 with a mass fraction of 20% sodium hydroxide aqueous solution. Thereafter, 0.5 kg of zinc sulfate, 0.5 kg of ferrous sulfate, 0.5 kg of copper sulfate, 2 kg of borax, and 1 kg of magnesium sulfate were added and stirred for 1.5 hours. Thereafter, 5 kg of urea, 5 kg of ammonium polyphosphate, 10 kg of potassium dihydrogen phosphate, 0.1 kg of alginic acid, 5 kg of potassium humate and 0.2 kg of hydroxypropyl methylcellulose were added to the reaction system, and 0.01 kg of sodium nitrophenolate, naphthalene Acetic acid 0.1kg and surfactant Tween-20 0.05kg, then stirred for 2 hours to obtain the foliage preparation of the present invention.

preparation Embodiment 3

[0049] 50 kg of amino acid fermentation waste liquid (wherein the solid content is 25 kg, and the water-soluble organic matter content is 14 kg) is heated to 75 degrees Celsius, and then the pH of the amino acid fermentation waste liquid is adjusted to 6.0 with a mass fraction of 20% sodium hydroxide aqueous solution. Thereafter, 0.5 kg of zinc sulfate, 0.5 kg of ferrous sulfate, 0.5 kg of copper sulfate, 2 kg of borax, and 1 kg of magnesium sulfate were added and stirred for 1.5 hours. After that, add 5 kg of urea, 5 kg of ammonium polyphosphate, 10 kg of potassium dihydrogen phosphate, 5 kg of potassium sulfate, 0.1 kg of alginic acid, 5 kg of potassium humate and 0.2 kg of hydroxypropyl methylcellulose into the reaction system and slowly add sodium nitrophenolate 0.01kg, 0.1kg of naphthaleneacetic acid and 0.05kg of surfactant Tween-20, and then stirred for 2 hours to obtain the foliage preparation of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com