Silica gel glass fabric hot-pressing buffer material and preparation method thereof

A technology of silica gel fiberglass cloth and cushioning materials, which is applied in the field of hot-pressed cushioning materials, can solve the problems of low pressing times, pressure resistance, and high production costs, and achieve high compression resistance, resilience, high resilience and Effect of release property and high tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as figure 1 As shown, a kind of silica gel glass fiber cloth hot-pressing buffer material proposed by the present invention includes a liquid silica gel layer, a thermally conductive silica gel layer and a glass fiber cloth coated with a silane coupling agent on both sides. The silane coupling agent facilitates the formation of the glass fiber cloth The two sides can better fit the silicone layer to prevent delamination; the silane coupling agent is diluted in advance with 2 times the diluent, and the fluidity of the silane coupling agent can be increased after dilution to facilitate its uniform application; the thickness of the glass fiber cloth 0.015mm, one side of the glass fiber cloth is coated with a liquid silicone layer after drying, and the other side is calendered with a composite thermal silica layer;

[0041] In this embodiment, the liquid silica gel layer is a mixture of liquid silica gel, a heat-resistant agent and alumina, wherein a platinum curing ag...

Embodiment 2

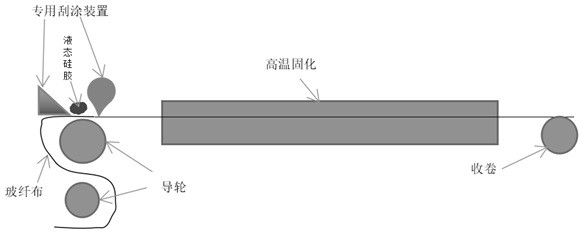

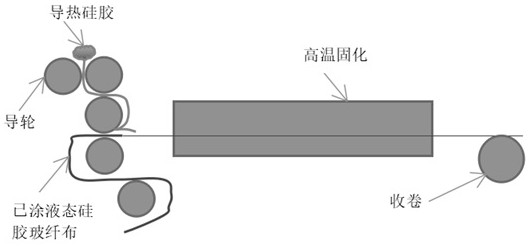

[0051] Such as Figure 2-3 As shown, the preparation method of a kind of silica gel glass fiber cloth hot-press buffer material provided by the invention comprises the following steps:

[0052] (1) Stirring and mixing of liquid silica gel: Add 50g of heat-resistant agent to 800g of liquid silica gel, then add 100g of alumina, put it into a vacuum mixer, stir at a speed of 600r / min for 20 minutes, and stir evenly to obtain A for later use;

[0053] (2) Solid silica gel modified thermally conductive silica gel: Use an internal mixer to fill 1000g of solid silica gel with 3000g of alumina at a temperature of 35°C and a pressure of 12KPa. The thermal conductivity of the solid silica gel filled with alumina is 1.1 W / m· Degree, get B spare;

[0054] (3) Surface treatment of glass fiber cloth: use coating equipment to coat both sides of glass fiber cloth with a thickness of 0.015mm with silane coupling agent. After covering, enter the oven through the guide wheel and bake at a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com