Punch forming device and punch forming process of square paper box component

A stamping forming and carton technology, applied in papermaking, paper/cardboard containers, box making operations, etc., can solve problems such as slow production speed, not clear enough, not straight enough cardboard, etc., to improve production speed and ensure molding quality , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

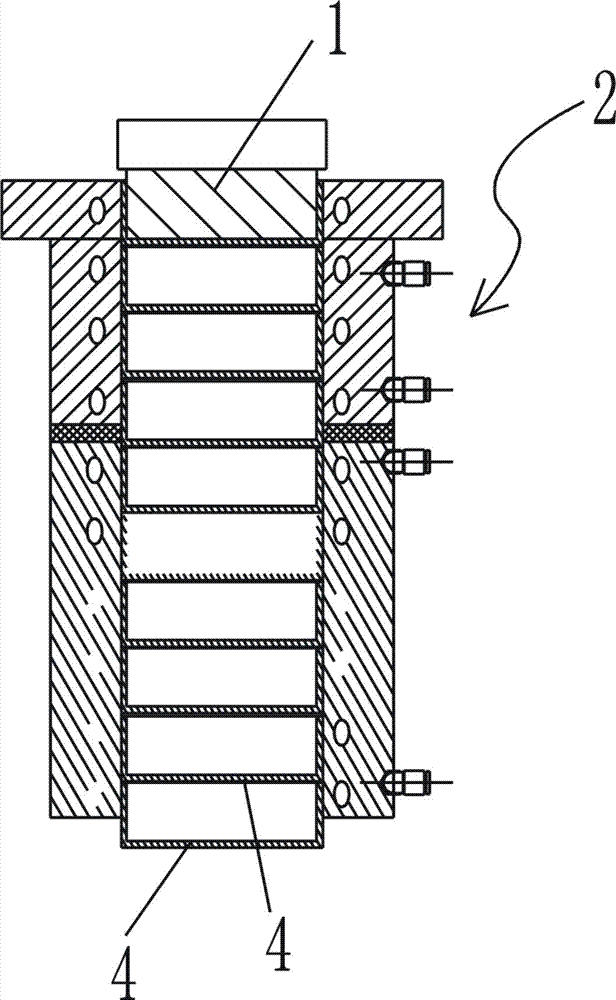

[0040] image 3 , Figure 4 As shown, the stamping and forming equipment of the square carton member includes an outer mold 2 and an inner mold 1, and the outer mold 2 is fixedly installed on the frame, so its vertical position is fixed, the inner mold 1 is in the shape of a cuboid, and the outer mold 2 forms a A cavity 21 for the inner mold to embed downwards, the outer mold cavity 21 is also in the shape of a cuboid, and the upper part of the outer mold cavity 21 is open, and the bottom of the outer mold cavity is hollowed out to form an outlet 210; the inner mold 1 can be relatively The outer mold 2 moves vertically, and a vertical driving mechanism (not shown in the figure) is also provided, and the vertical driving mechanism drives and connects the inner mold 1, and the inner mold 1 can be embedded downward under the driving action of the vertical driving mechanism Outer mold cavity 21.

[0041] Both the inner mold and the outer mold are made of metal; the outer mold ca...

Embodiment 2

[0047] A stamping and forming process for a square carton member, characterized in that the stamping and forming equipment of Embodiment 1 is used, and includes the following steps:

[0048] (1) The cooling channel 25 is fed with cooling water to cool the lower section 23 of the outer mold body; at the same time, the heating channel 24 is fed with heating oil to heat the upper section 22 of the outer mold body;

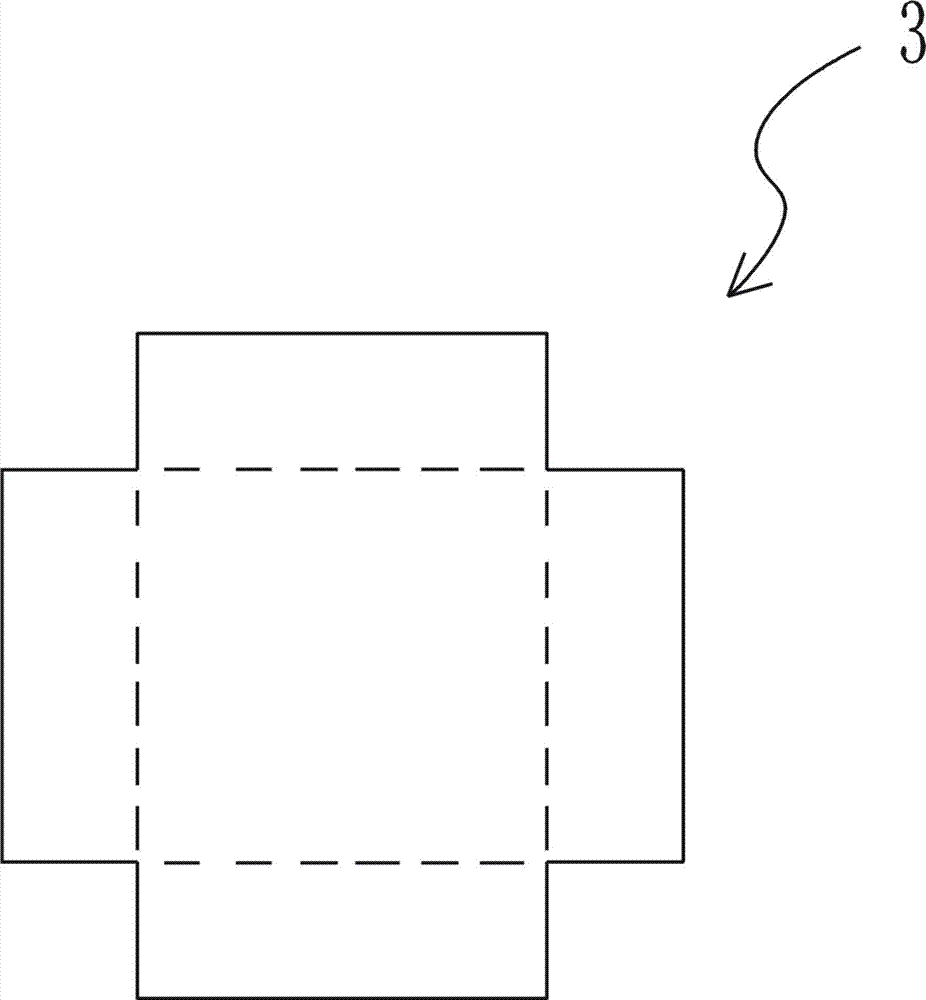

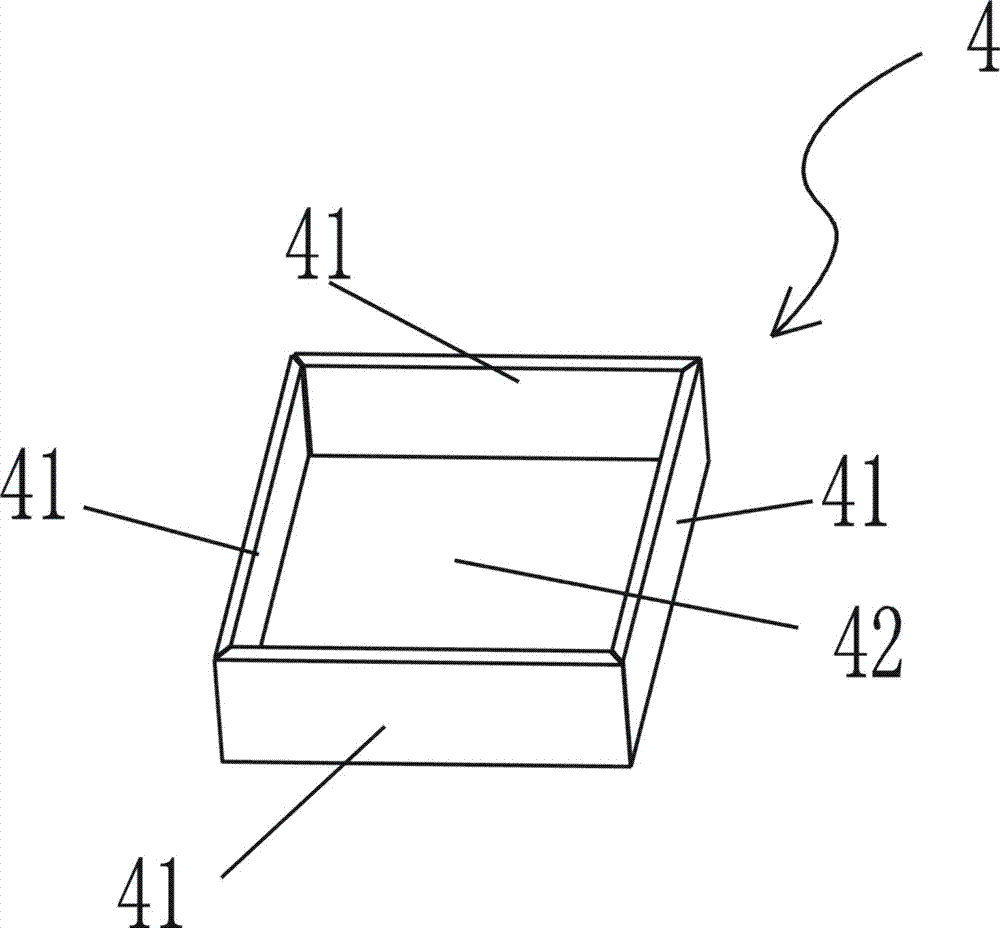

[0049] (2), will figure 1 The quasi-cross-shaped cardboard 3 of shown shape is placed on the outer mold 2, and the central part of the quasi-cross-shaped cardboard 3 is aligned with the cavity 21 of the outer mold, as Figure 5 As shown; the vertical drive mechanism makes the inner mold 1 punch down, and the inner mold 1 and the outer mold 2 work together to push the four edge regions of the quasi-cross-shaped cardboard along the figure 1 Shown dotted line position bends 90 °, forms square carton member parison 4, as Image 6 Shown, the three-dimensional shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com