Ancient building eaves bar forming mold

A technology for forming molds and eaves, which is applied in the field of molding molds for ancient building eaves, which can solve the problems of high site requirements for eaves, single structure solidification, and poor molding quality, and achieve good molding quality, simple and convenient mold installation and removal , High molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

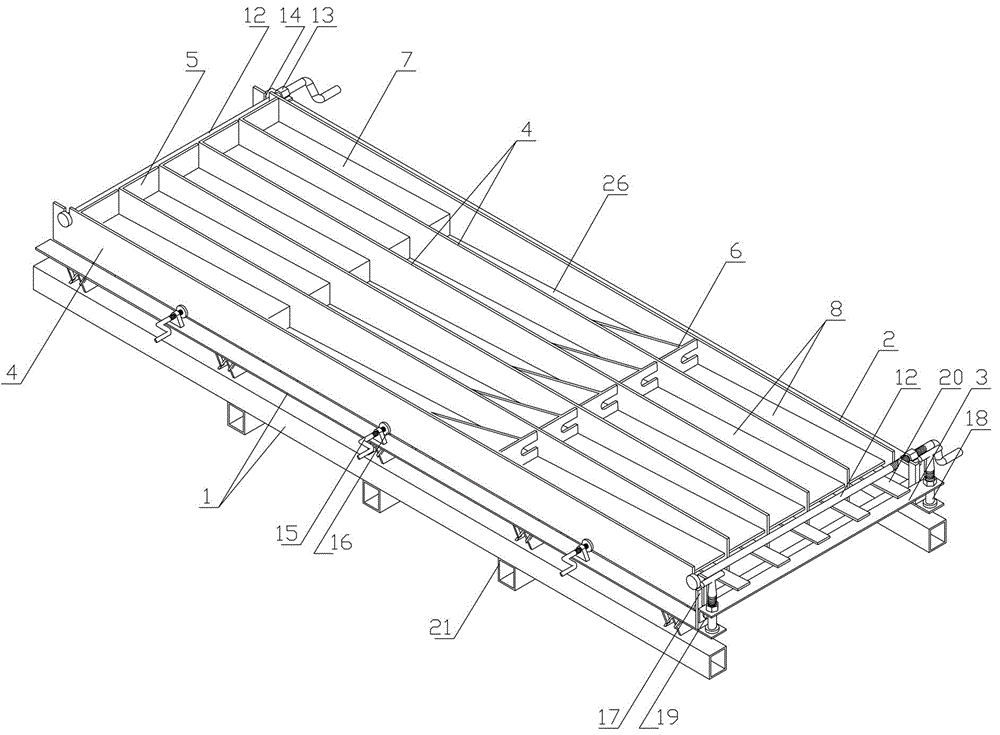

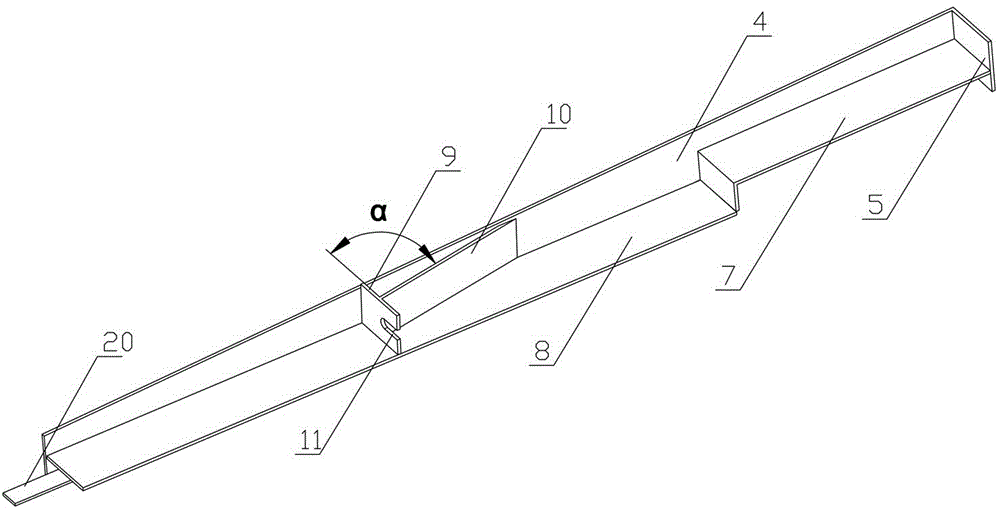

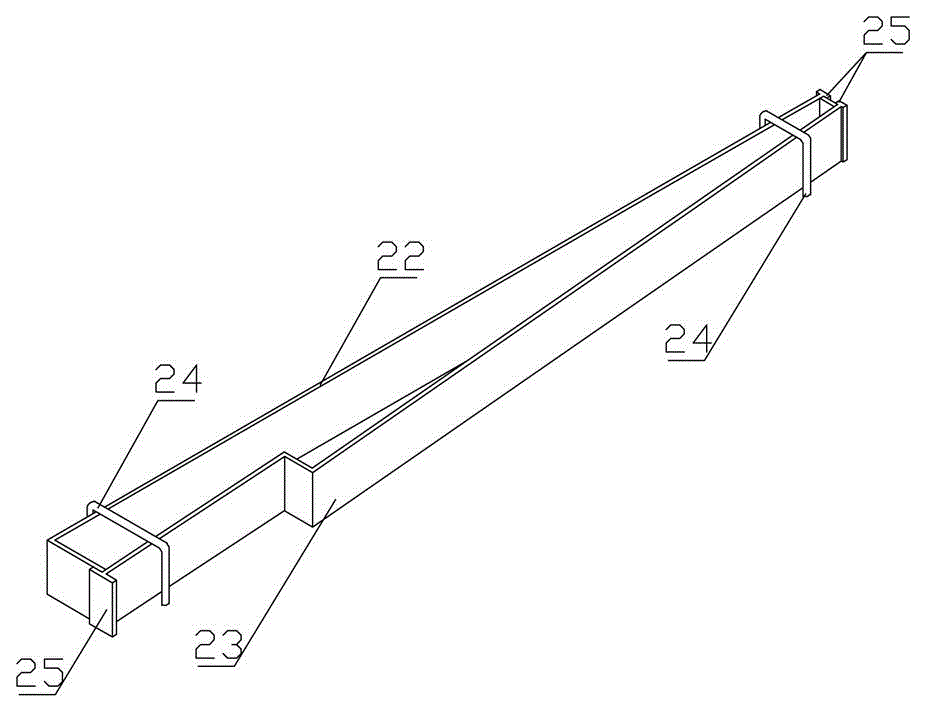

[0025] see figure 1 , figure 2 , the present invention has a base 1, a stent 2 is welded on the right side of the base 1 (the stent 2 can also be welded on the left side of the base 1), and on the base 1 along the left side of the stent 2 There are several mold units arranged side by side, and the mold units are fastened by locking devices. Two lifting mechanisms arranged symmetrically on the left and right are installed at the rear end of the base 1, and a horizontally arranged support beam 3 is installed on the lifting mechanism. , the mold unit is composed of a movable mold side 4, a front stopper 5 and a rear stopper 6, and a fixed bottom plate 7 and a movable bottom plate 8 arranged front and back, the front stopper 5 is welded on the front end of the movable mold side 4, and It forms an "L"-shaped structure with the movable mold side 4, and the fixed bottom plate 7 is welded on the inner side of the movable mold side 4 and the front stopper 5, and has a "7"-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com