Stamping equipment and stamping process for square carton components

A stamping forming and carton technology, which is applied in papermaking, paper/cardboard containers, box production operations, etc., can solve the problems of square carton components with insufficient square corners, slow production speed, and insufficient clarity, etc., and achieve good curing and shaping effects, The effect of increasing production speed and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

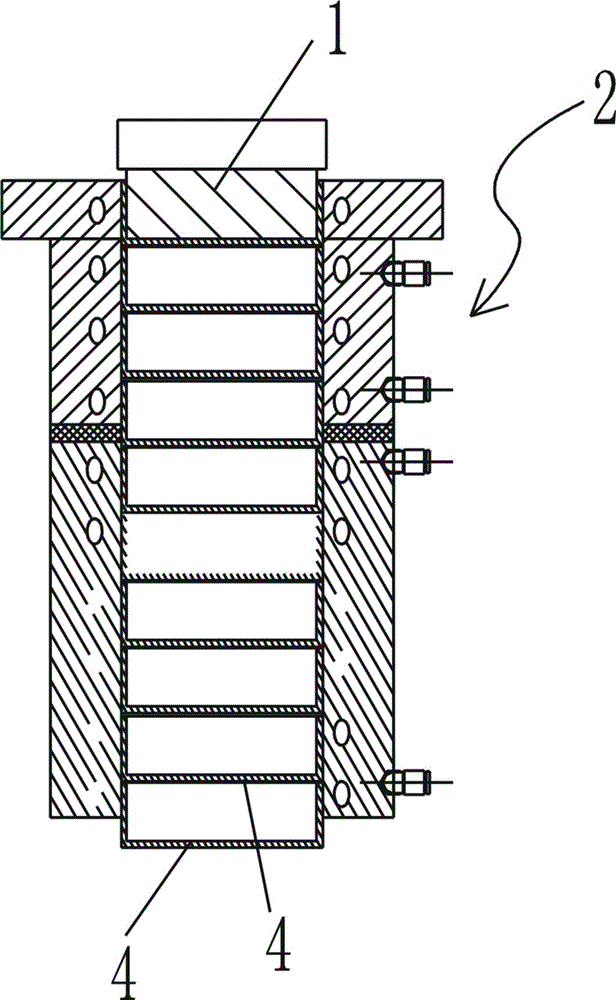

[0039] image 3 , Figure 4 As shown, the stamping and forming equipment of the square carton member includes an outer mold 2 and an inner mold 1. The outer mold 2 is fixedly installed on the frame, so its vertical position is fixed, the inner mold 1 is in the shape of a cuboid, and the outer mold 2 is formed with A cavity 21 for the inner mold to be embedded downward, the outer mold cavity 21 is also in the shape of a cuboid, the upper part of the outer mold cavity 21 is open, and the bottom of the outer mold cavity is hollowed out to form an outlet 210; the inner mold 1 can be opposite to The outer mold 2 moves vertically, and is also provided with a vertical drive mechanism (not shown in the figure), which drives and connects the inner mold 1, and the inner mold 1 can be embedded downward under the driving action of the vertical driving mechanism. Outer mold cavity 21 .

[0040] Both the inner mold and the outer mold are made of metal; the outer mold cavity 21 is divided ...

Embodiment 2

[0045] A stamping and forming process for a square carton member is characterized by adopting the stamping and forming equipment of the first embodiment, and comprising the following steps:

[0046] (1) Cooling water is introduced into the cooling channel 25 to cool the lower section 23 of the outer mold body; at the same time, heating oil is introduced into the heating channel 24 to heat the upper section 22 of the outer mold body;

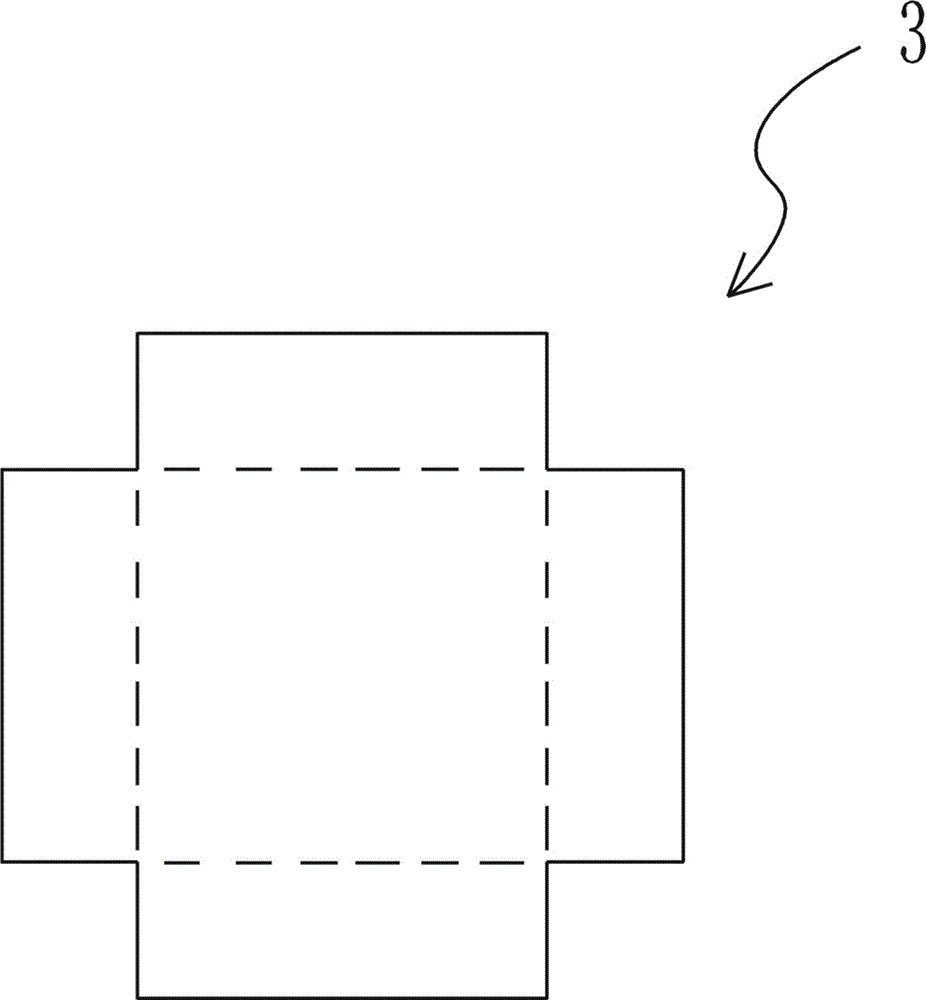

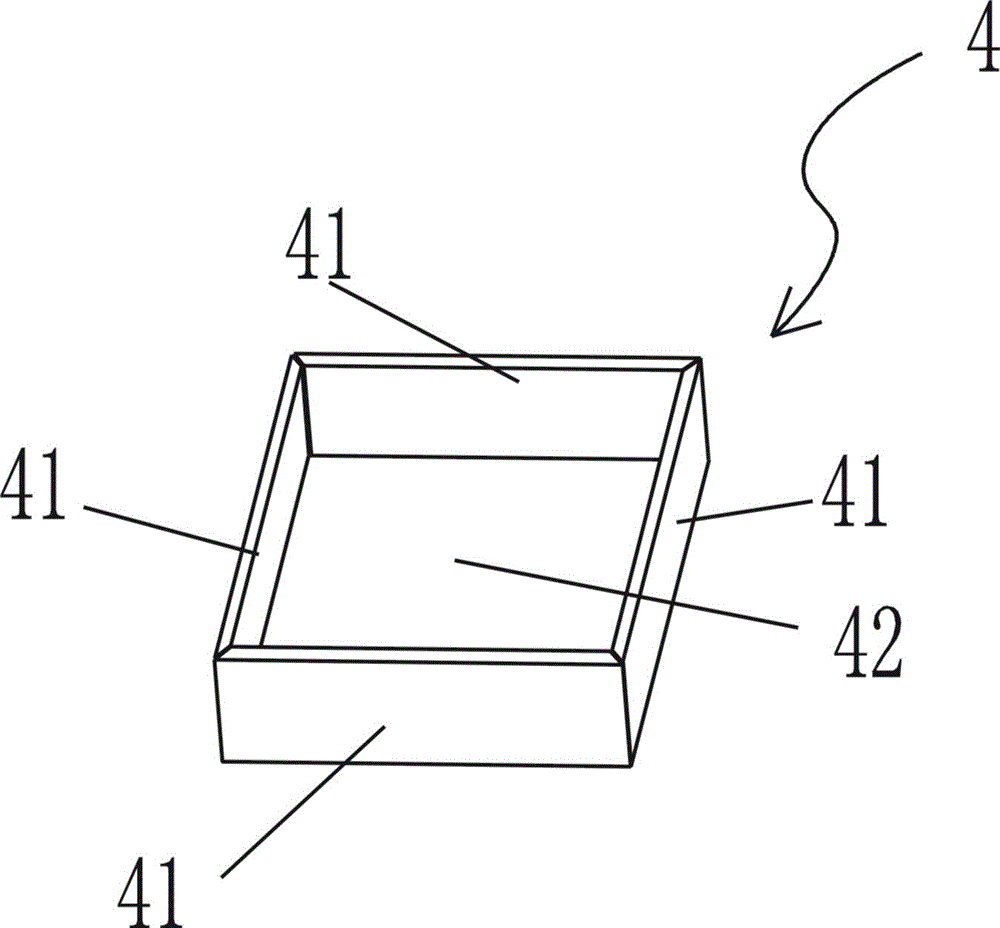

[0047] (2), will figure 1 The quasi-cross-shaped cardboard 3 of the shown shape is placed on the outer mold 2, and the central part of the quasi-cross-shaped cardboard 3 is aligned with the cavity 21 of the outer mold, such as Figure 5 As shown; the vertical drive mechanism makes the inner mold 1 punch down, and the inner mold 1 and the outer mold 2 work together to move the four edge areas of the quasi-cross-shaped cardboard along the figure 1 The dotted line shown is bent at 90° to form a square carton component parison 4, as shown in Image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com