Cutter set for processing anti-cracking grooves of autoclaved aerated concrete plates

An autoclaved aerated concrete slab technology, which is applied in stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of poor surface quality of autoclaved aerated concrete slabs, inconvenient use and replacement, etc., to save daily life The effect of maintenance cost, saving electric energy and improving environmental cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

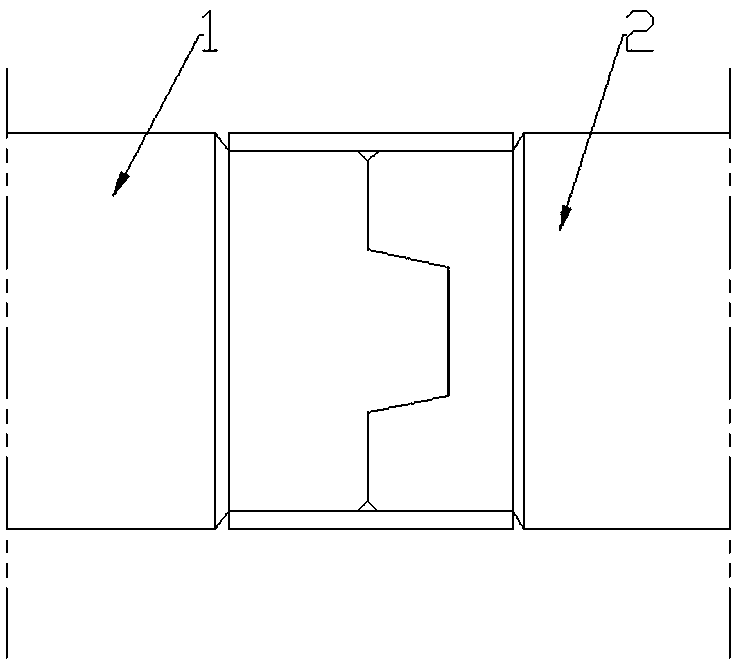

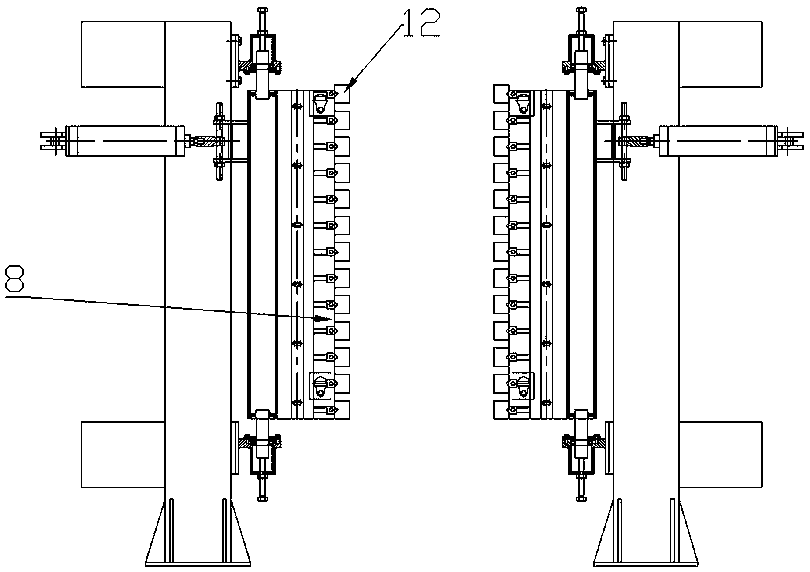

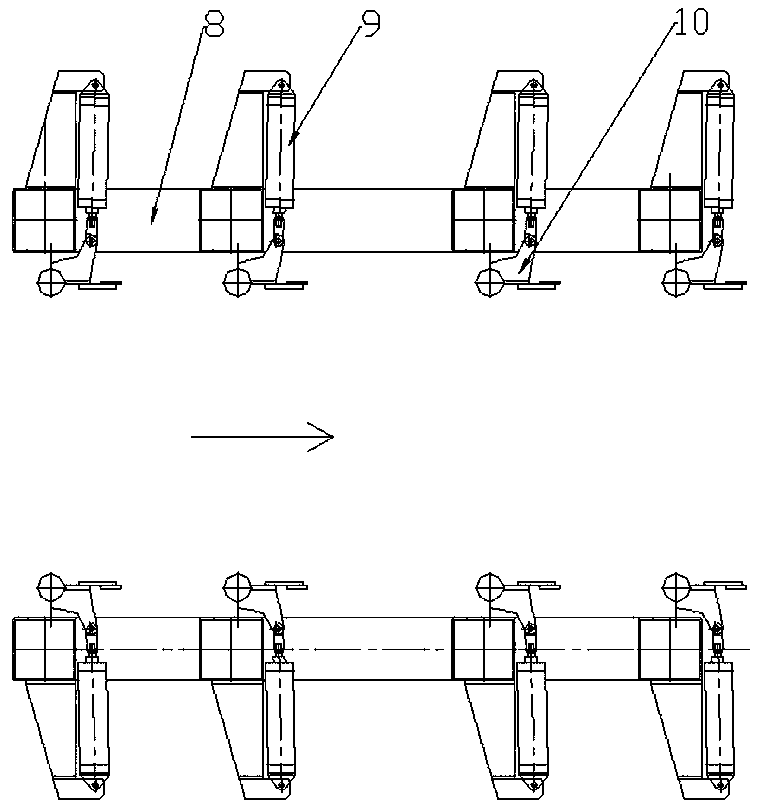

[0036] Such as Figure 1 to Figure 11 Shown is a tool set for processing anti-cracking grooves of autoclaved aerated concrete panels. A bump that matches the anti-crack groove 2 is provided, and the tool set includes a first tool set for processing the bump, a second tool set for processing the anti-crack groove 2 and a tool for fixing the tool set Fixing plate 8, two uprights are arranged on the ground relatively along the vertical direction, and two described tool fixing plates 8 are detachably installed on opposite sides of the two uprights respectively, wherein:

[0037] At least two autoclaved aerated concrete slabs 1 to be processed are stacked along the vertical direction to form an autoclaved aerated concrete slab group, and the autoclaved aerated concrete slab group is placed between two columns along the length direction of the auto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com