Honeycomb panel edge covering device and edge covering process

An edge-wrapping device and honeycomb panel technology, applied in the field of panel processing, can solve the problems that the edge-banding material cannot fully fill the side of the honeycomb panel, poor versatility, and easy to pollute the panel surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

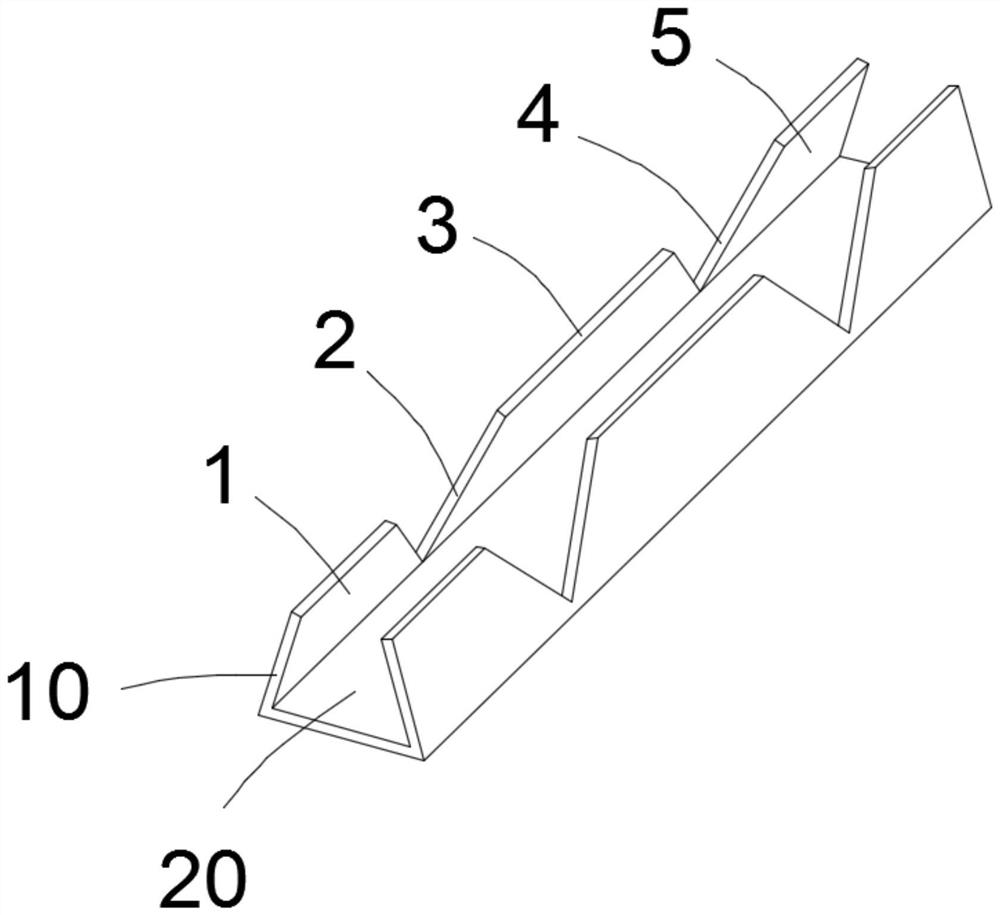

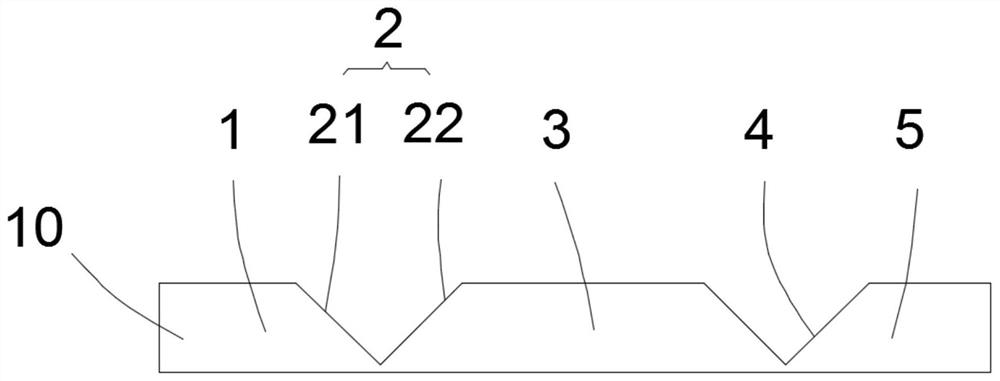

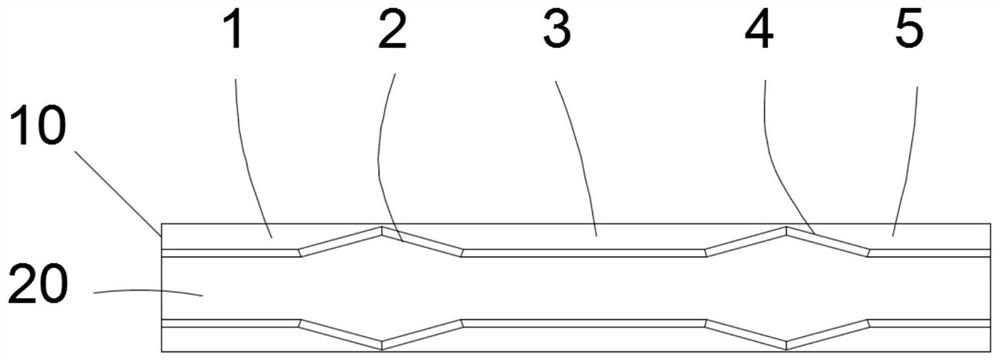

[0034] Such as Figure 1-3 As shown, an edge wrapping device for a honeycomb panel includes a strip-shaped main body 10, and the inside of the main body 10 is provided with a through groove 20 with an upper end opening and passing through the main body 10 from left to right. The main body 10 includes sequentially connected first A movable block 1, a fixed block 3 and a second movable block 5, the first movable block 1 is relatively rotatably connected with the fixed block 3, and the second movable block 5 is relatively rotatably connected with the fixed block 3; wherein , The length ratio of the first movable block 1, the fixed block 3 and the second movable block 5 is 1:2:1, the main body 10 is integrally formed, and the main body 10 is made of elastic resin with a smooth surface.

[0035] Such as Figure 2-4 As shown, the main body 10 includes a bottom plate 13 and a splint connected to the bottom plate 13, the splint includes a first splint 11 and a second splint 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com