Synthetic process of high self-sharpening diamond

A synthesis process and diamond technology, applied in the field of high self-sharpening diamond synthesis technology, can solve the problems of short service life and poor self-sharpening of diamond abrasive grains, and achieve the effect of improving service life, good self-sharpening and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 Concrete synthetic process step is:

[0049] ①Take 400 mesh or more fine graphite powder and Mn-based alloy catalyst powder, and mix the raw materials at a weight ratio of 6:4. The components of the Mn-based alloy catalyst powder are calculated by weight percentage: Ni: 15%, Cu: 8 %, Fe: 1%, Cr: 0.06%, V: 0.02%, Ce: 0.001%, dispersant: 1.2%, and the balance is Mn;

[0050] ②Put the raw materials in step ① into the three-dimensional mixer and mix for 6 hours. After isostatic pressing at 100MPa, crush them into fine particles with a size of 90 mesh or more, and then put them in a vacuum furnace for 58 minutes at 900°C to fully remove oxygen. Cool down to room temperature to obtain the mixed material;

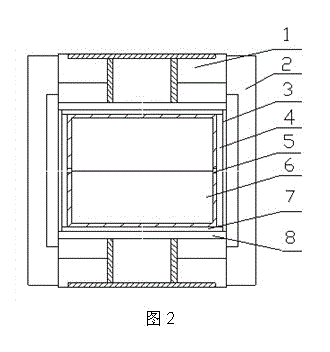

[0051] ③Put the mixed material into the mold, and then press it into a columnar core column on a four-column press. The size of the core column is Φ40mm×31.5mm, and the density of the core column is 3.4g / cm 3 ;

[0052] ④Put the core column into the diamond ...

Embodiment 2

[0057] Embodiment 2 Concrete synthetic process steps are:

[0058] ①Take 400 mesh finer graphite powder and Mn-based alloy catalyst powder, and mix the raw materials in a ratio of 6:9 by weight. The components of Mn-based alloy catalyst powder are calculated by weight percentage: Ni: 21%, Cu: 11 %, Fe: 2%, Cr: 0.07%, V: 0.04%, Ce: 0.003%, dispersant: 1.8%, and the balance is Mn;

[0059] ②Put the raw materials of step ① into the three-dimensional mixer and mix for 7 hours. After isostatic pressing at 200MPa, crush them into fine particles of 90 mesh or less, and then put them in a vacuum furnace for 65 minutes at 1000°C to fully remove oxygen. Cool down to room temperature to obtain the mixed material;

[0060] ③Put the mixed material into the mold, and then press it into a columnar core column on a four-column press. The size of the core column is Φ40mm×31.5mm, and the density of the core column is 3.7g / cm 3 ;

[0061] ④ Put the core column into the diamond synthesis block...

Embodiment 3

[0066] Embodiment 3 Concrete synthetic process steps are:

[0067] ①Take 400 mesh finer graphite powder and Mn-based alloy catalyst powder, and mix the raw materials at a ratio of 6:7 by weight. The components of Mn-based alloy catalyst powder are calculated by weight percentage: Ni: 18%, Cu: 9.5 %, Fe: 1.5%, Cr: 0.065%, V: 0.03%, Ce: 0.002%, sodium lauryl sulfate: 1.5%, and the balance is Mn;

[0068] ②Put the raw materials in step ① into the three-dimensional mixer and mix for 6.5 hours. After isostatic pressing at 150MPa, crush them into fine particles of 90 mesh or less, and then put them in a vacuum furnace for 62 minutes at 950°C to fully remove oxygen. Cool down to room temperature naturally to obtain the mixed material;

[0069] ③Put the mixed material into the mold, and then press it into a columnar core column on a four-column press. The size of the core column is Φ40mm×31.5mm, and the density of the core column is 3.6g / cm 3 ;

[0070] ④Put the core column into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com