A kind of preparation method of 12cr2mo1 hot-rolled container steel plate

A technology for steel plates and containers is applied in the field of preparation of 12Cr2Mo1 hot-rolled container steel plates, which can solve the problems of low production efficiency and achieve the effects of high production efficiency, improved toughness, and promotion of nucleation and dispersion precipitation.

Inactive Publication Date: 2019-10-01

NORTHEASTERN UNIV LIAONING

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

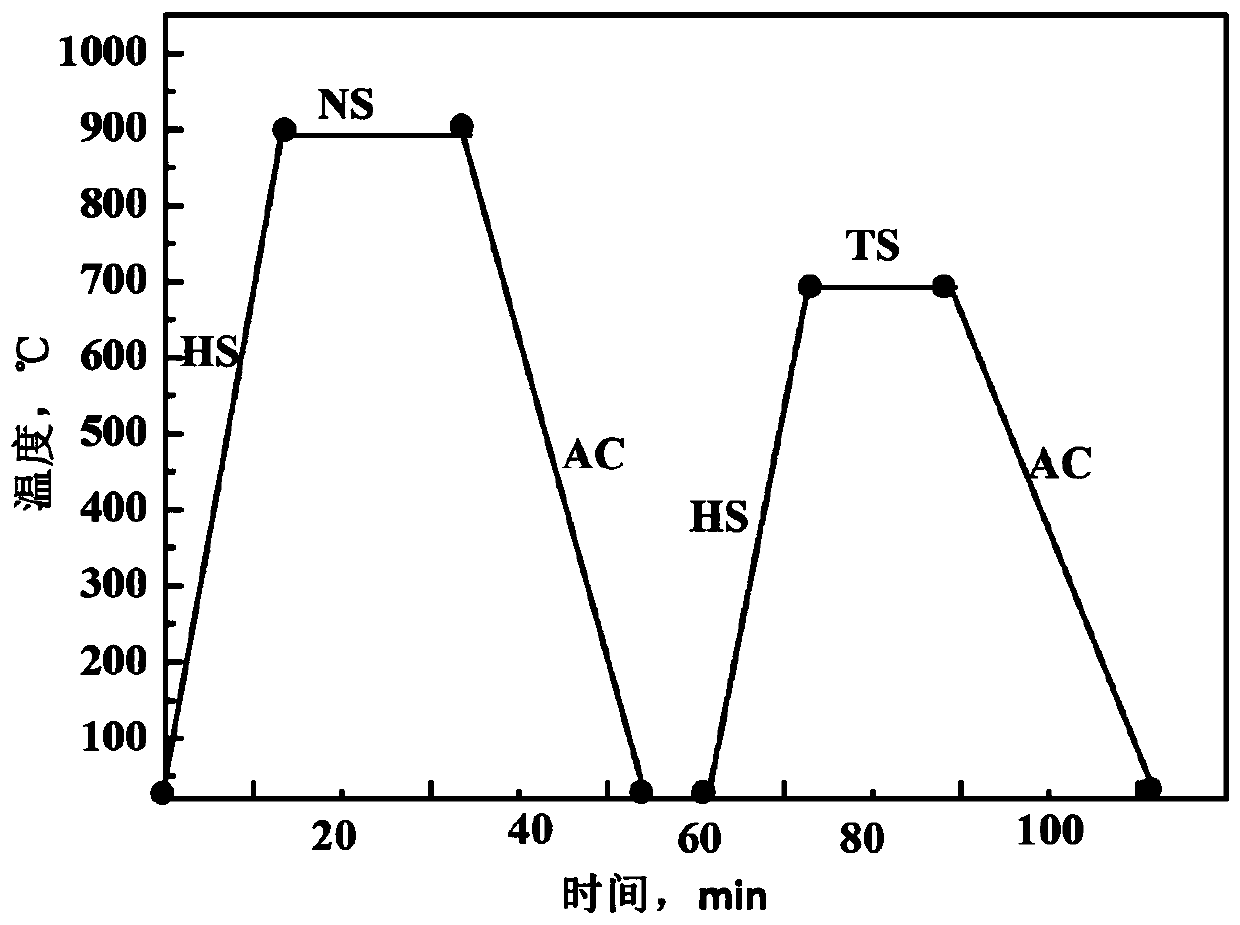

At present, the heat treatment process of 12Cr2Mo1 hot-rolled container steel plate is normalizing + tempering, but the production efficiency of this method is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

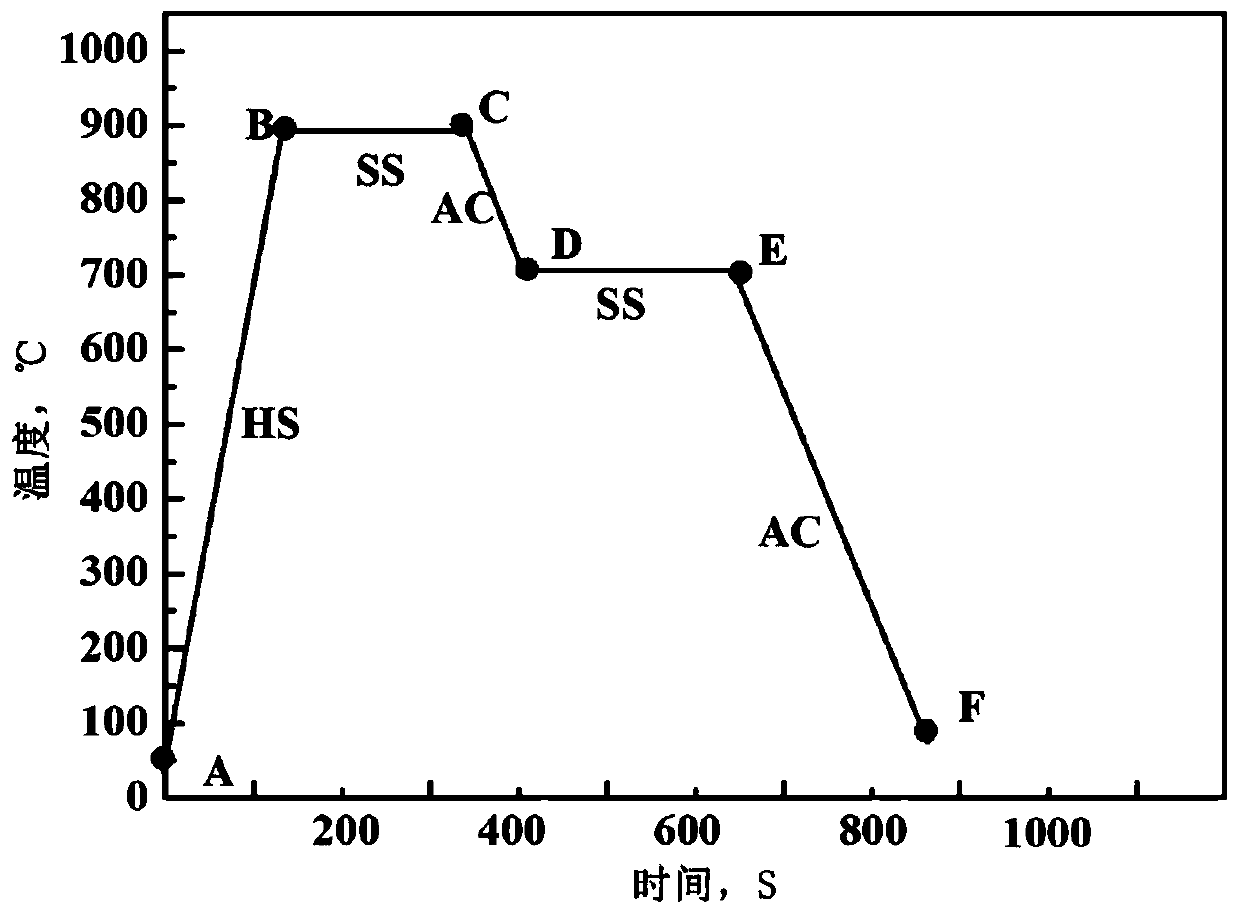

The invention relates to a preparation method of 12Cr2Mo1 hot-rolled container steel plates and belongs to the technical field of metallurgical materials. The preparation method of the present invention is as follows: heating the hot-rolled steel plate to 900-940°C, holding it for 30-50 minutes, and performing a primary heat preservation treatment; after the primary heat preservation treatment, cool it to 670-730°C, hold it for 20-30 minutes, and conduct a second heat preservation treatment. Heat preservation treatment, then lower to room temperature after secondary heat preservation treatment. The continuous heat treatment method of the present invention has high production efficiency.

Description

technical field The invention relates to a preparation method of a 12Cr2Mo1 hot-rolled container steel plate, belonging to the technical field of metallurgical materials. Background technique With the rapid development of petroleum, chemical and other industries, higher requirements are put forward for 12Cr2Mo1 hot-rolled container steel. 12Cr2Mo1 hot-rolled container steel has good structure and performance stability at medium and high temperature (375-595°C). At present, the heat treatment process of 12Cr2Mo1 hot-rolled container steel plate is normalizing + tempering, but the production efficiency of this method is low. Contents of the invention The present invention solves the above-mentioned problems by adopting a continuous heat treatment method. The invention provides a kind of preparation method of 12Cr2Mo1 hot-rolled container steel plate, and described preparation method is: Heat the hot-rolled steel plate to 900-940°C, keep it warm for 30-50 minutes, and p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D8/02C22C38/02C22C38/04C22C38/22C22C38/28

Inventor 李长生王期文涂兴洋陈洁陈礼清

Owner NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com