Heat-treated vanadium-containing high-boron high-speed steel and heat treatment method thereof

A heat treatment method and high-speed steel technology, applied to heat-treated vanadium-containing high-boron high-speed steel and its heat treatment field, can solve the problems of reduced strength and toughness, coarse boron carbides, grain boundary embrittlement, etc. Good abrasiveness, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A heat treatment method for vanadium-containing high-boron high-speed steel, comprising the following steps:

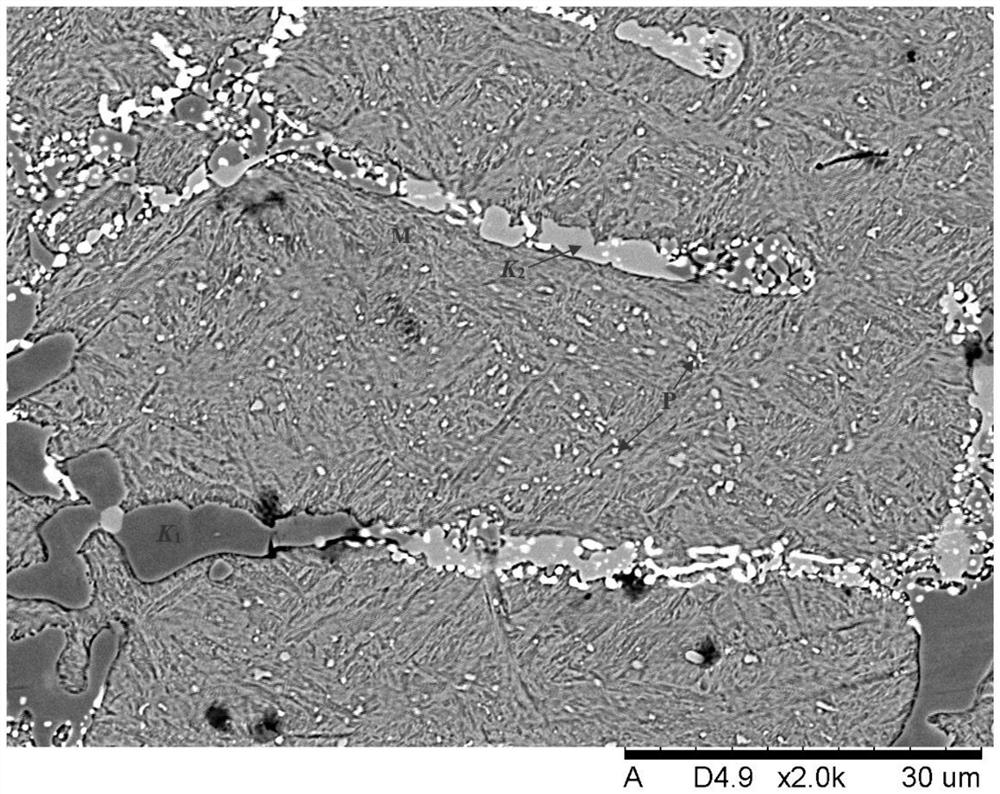

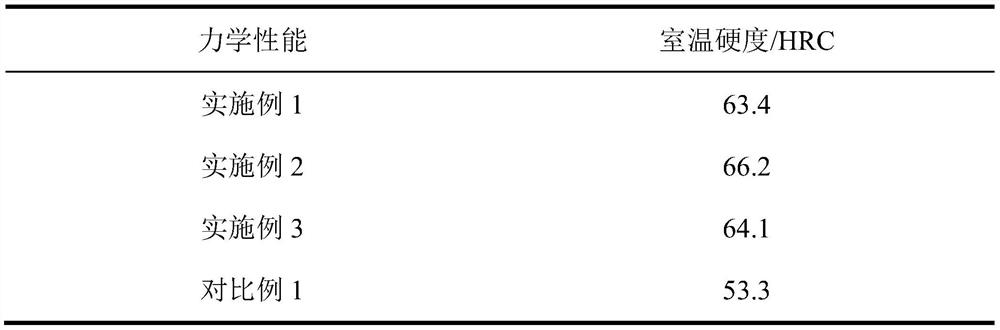

[0053] S1. Use vanadium-containing high-boron high-speed steel as the workpiece to be quenched. The composition of V-containing high-boron high-speed steel includes C: 0.37%, B: 1.44%, Cr: 4.77%, Si: 0.58%, and Mn: 0.61%, W: 1.16%, Mo: 0.63%, Ti: 0.07%, Al: 0.58%, V: 1.00%, the rest is Fe and unavoidable trace impurities;

[0054] S2. Raise the quenched workpiece in step S1 to 1010° C., keep it warm for 110 minutes, and then carry out oil cooling at room temperature to complete the quenching treatment to obtain the quenched workpiece;

[0055] S3. Perform two tempering treatments on the quenched parts in step S2. The first tempering process is to raise from room temperature to 510 ° C, the heating time is 100 minutes, and air cool to room temperature after 1.5 hours of heat preservation; the second tempering process is from room temperature Raise to 450°C, the...

Embodiment 2

[0058] A heat treatment method for vanadium-containing high-boron high-speed steel, comprising the following steps:

[0059] S1. Use vanadium-containing high-boron high-speed steel as the workpiece to be quenched. The composition of V-containing high-boron high-speed steel includes C: 0.40%, B: 1.50%, Cr: 4.80%, Si: 0.63%, Mn: 0.68%, W: 1.20%, Mo: 0.65%, Ti: 0.09%, Al: 0.60%, V: 2.05%, the rest is Fe and unavoidable trace impurities;

[0060] S2. Elevate the quenched workpiece in step S1 to 1050°C, heat it for 120 minutes, and then perform oil cooling at room temperature to complete the quenching treatment to obtain the quenched workpiece;

[0061] S3. Perform two tempering treatments on the quenched parts in step S2. The first tempering process is to raise the temperature from room temperature to 525 ° C, the heating time is 120 minutes, and air cool to room temperature after 2 hours of heat preservation; The temperature is as high as 475°C, the heating time is 120min, and t...

Embodiment 3

[0063] A heat treatment method for vanadium-containing high-boron high-speed steel, comprising the following steps:

[0064] S1. Use vanadium-containing high-boron high-speed steel as the workpiece to be quenched. The composition of V-containing high-boron high-speed steel includes C: 0.44%, B: 1.61%, Cr: 4.83%, Si: 0.68%, and Mn: 0.80%, W: 1.24%, Mo: 0.67%, Ti: 0.12%, Al: 0.63%, V: 3.00%, the rest is Fe and unavoidable trace impurities;

[0065] S2. Elevate the quenched workpiece in step S1 to 1060° C., keep it warm for 150 minutes, and then perform oil cooling at room temperature to complete the quenching treatment to obtain the quenched workpiece;

[0066] S3. Perform two tempering treatments on the quenched parts in step S2. The first tempering process is from room temperature to 550 ° C, the heating time is 130 minutes, and air cooling to room temperature after 2.5 hours of heat preservation; the second tempering process is from room temperature Raise to 490°C, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com