Alloying method for restraining aluminum alloy recrystallization

A technology for alloying and aluminum alloys, which is applied in the field of alloying to inhibit recrystallization of aluminum alloys, can solve the problems of increasing alloy costs, restricting the application and promotion of Sc-containing aluminum alloys, and the high price of rare earth Sc, so as to suppress recrystallization and reduce costs. Low, good deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the chemical composition range of the alloying method of the present invention, the required alloyed samples are prepared and processed, and the preparation process is as follows:

[0046] According to the designed chemical composition ratio of Zr 0.15%, Ti 0.15%, Al 99.7%, the domestic raw materials Al-10Ti, Al-10Zr master alloy and high-purity aluminum are weighed for batching. Put all the prepared ingredients into the vacuum high-frequency electromagnetic oscillating electric arc furnace, and pump the vacuum to 6×10 -2 Pa~8×10 -3 Pa, then feed 0.05MPa high-purity argon gas into the smelting vacuum chamber, and then set the furnace temperature to a predetermined temperature until all the ingredients are melted, keep it warm for 5 minutes under electromagnetic vibration, and then pour it into a water-cooled copper mold to make Alloyed samples were obtained.

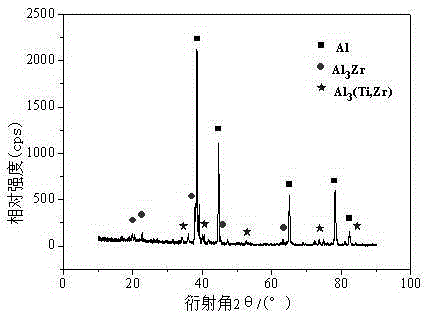

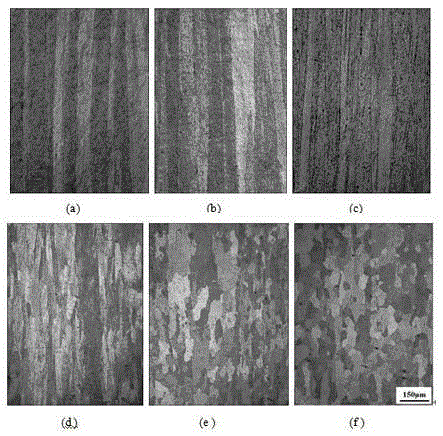

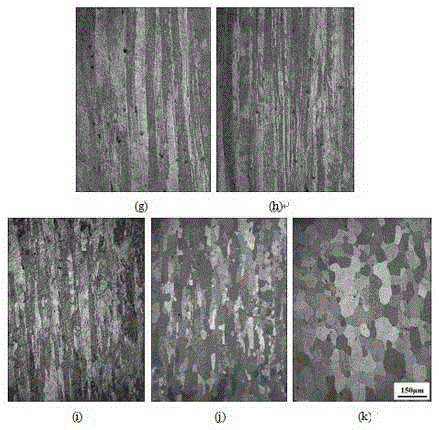

[0047] The effects of Ti, Zr composite alloying and Ti, Zr single alloying on alloy recrystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com