Method for improving high temperature plasticity of steel

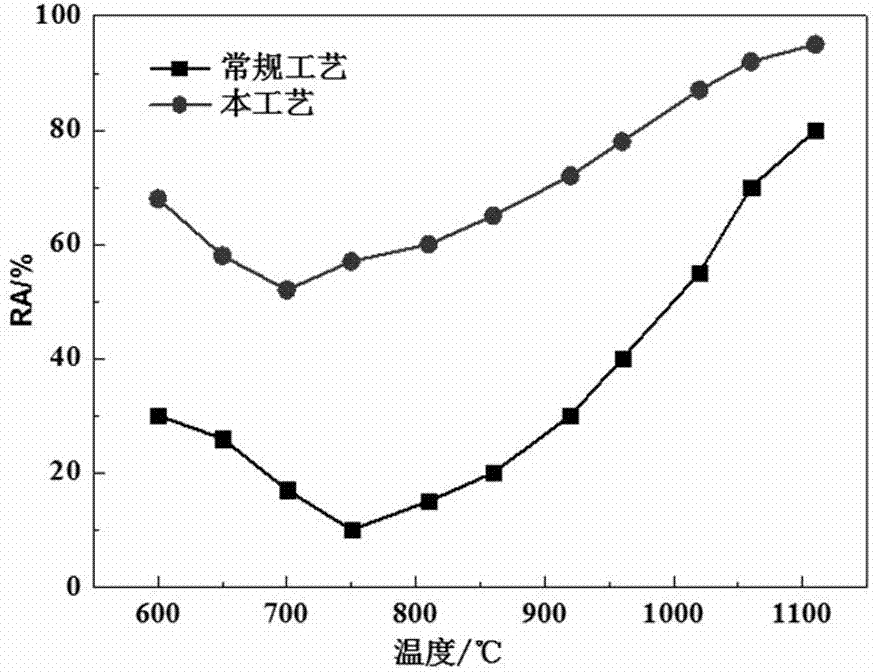

A technology of high-temperature plasticity and high-strength steel, which is applied in the field of steelmaking and continuous casting, can solve the problems that the pro-eutectoid ferrite structure cannot be suppressed at the same time, and the segregation behavior cannot be effectively eliminated, so as to achieve the effect of improving high-temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A domestic steel plant uses a 240t converter to smelt steel micro-alloy steel. The composition of the steel is 0.09%C-0.25%Si-1.53%Mn-0.035%Nb-0.021%Ti. Because the aluminum deoxidized steel contains 0.35%Al element . The steel production route is BOF→LF→Mg treatment→CC. After the alloying of converter tapping is completed, it is sent to the LF station for desulfurization and refining treatment, adding alloy elements to obtain micro-alloyed molten steel, and the wire feeding operation is carried out in the later stage of refining. The aluminum-magnesium-iron composite cored wire contains 10% magnesium and 35% aluminum , the rest is iron, with a diameter of 15mm, wrapped by 0.5mm iron sheet, the wire feeding speed is 3.0m / s, the feeding amount is 350 m / furnace, and then the argon gas blowing volume is 45L / min. The magnesium content in it is kept at 20ppm. Send it to the continuous casting platform for pouring, the tundish capacity is 45t, the stable liquid level height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com