Preparation method of 12Cr2Mo1 hot-rolling container steel plate

A steel plate and container technology, which is applied in the field of preparation of 12Cr2Mo1 hot-rolled container steel plates, can solve the problems of low production efficiency, achieve high production efficiency, improve tensile strength and crack growth resistance, and promote nucleation and disperse precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

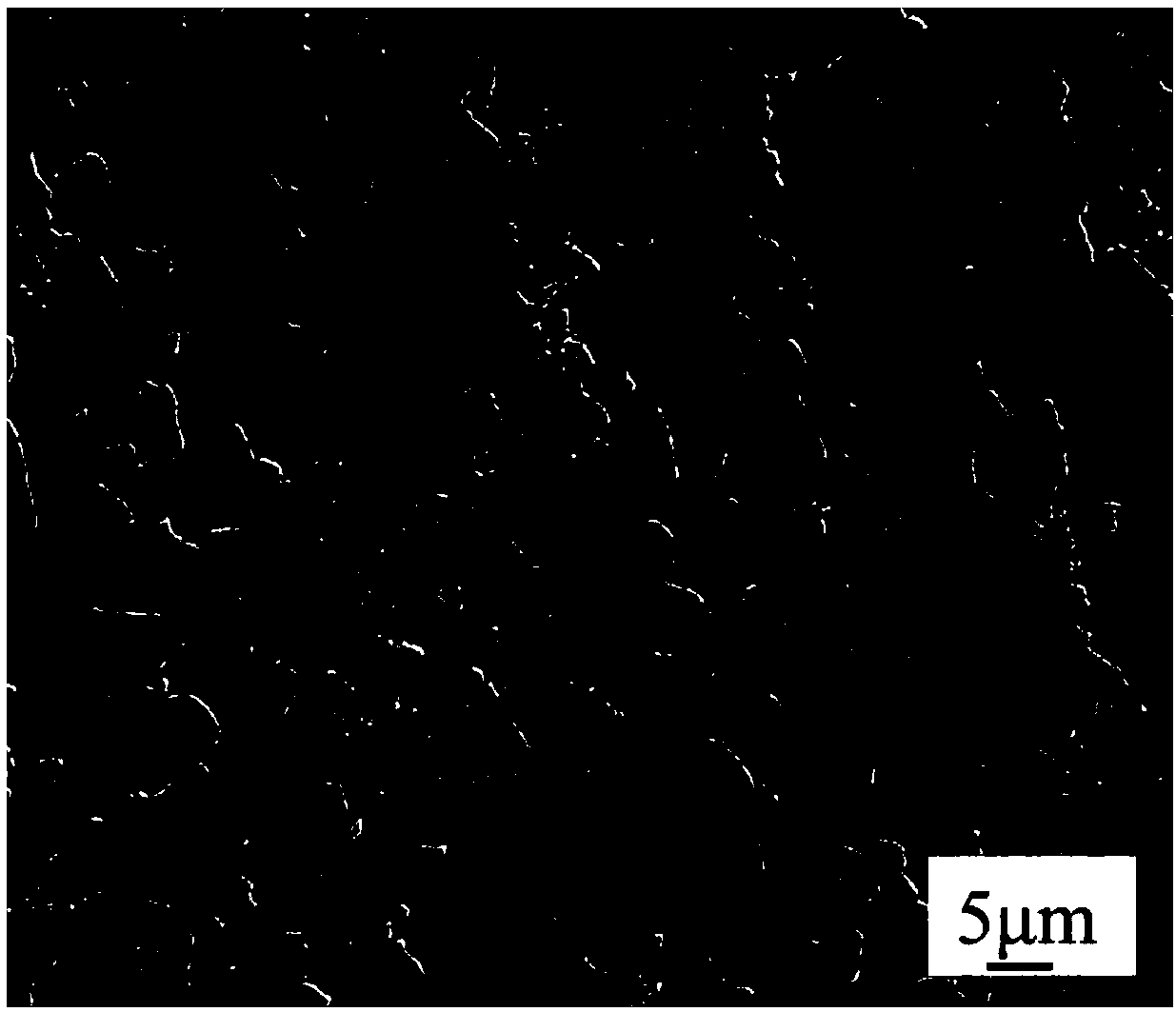

Examples

Embodiment 1

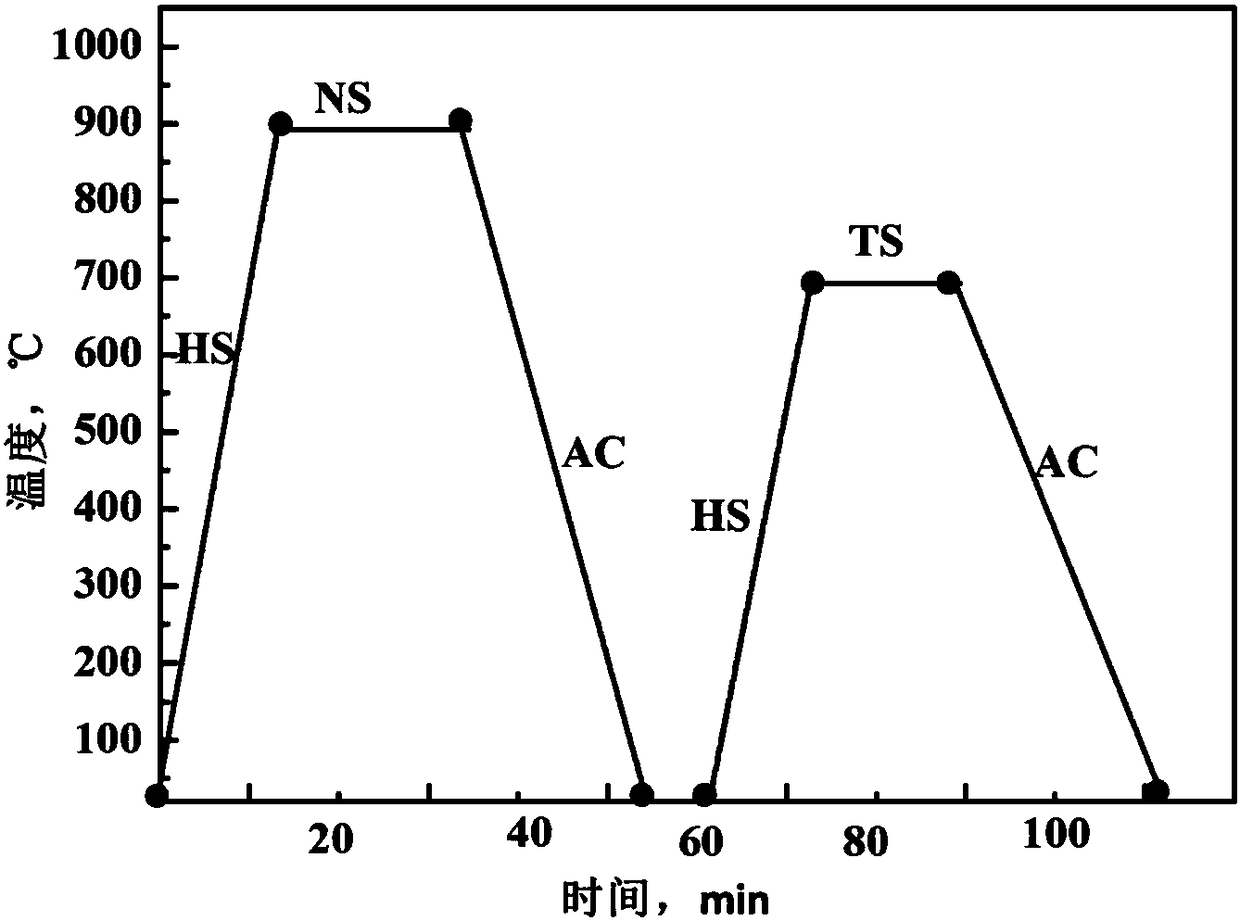

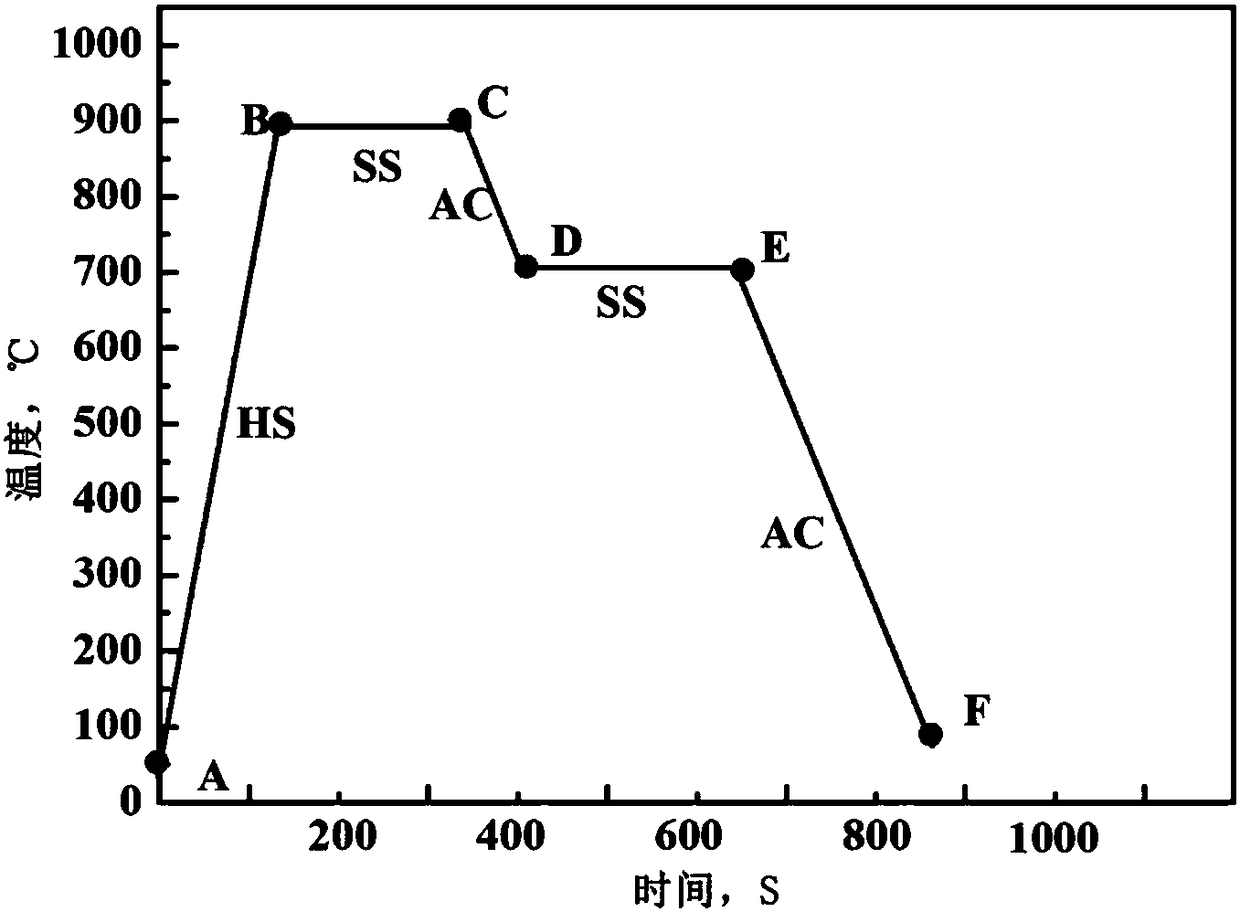

[0031] A kind of preparation method of 12Cr2Mo1 hot-rolled container steel plate, described preparation method comprises the steps:

[0032] ①Molten steel is smelted according to the designed composition and continuously cast into a 220mm thick slab. The composition by weight percentage is: C0.12%, Si 0.15%, Mn 0.4-0.6%, Cr 2.18%, Mo 1%, Ti 0.03% , P≤0.01%, S≤0.003%, Sn≤0.008%, As≤0.01%, Sb≤0.003%, Pb≤0.01%, N≤0.006%, Fe balance;

[0033] ②Heat the product obtained in step ① to 1200°C and keep it warm for 1 hour. 6 passes, with a total reduction rate of 76.82%; the start rolling temperature of the finish rolling is 920°C, the finish rolling temperature is 850°C, and the rolling is 5 passes, with a total reduction rate of 76%, to obtain a 12mm thick steel plate;

[0034] ③The product obtained in step ② is leveled one by one, and after hot rolling, it is cooled to 600°C with water at a cooling rate of 30°C / s, and then air-cooled to room temperature;

[0035] ④Heat the product...

Embodiment 2

[0039] A kind of preparation method of 12Cr2Mo1 hot-rolled container steel plate, described preparation method comprises the steps:

[0040] ①Molten steel is smelted according to the designed composition and continuously cast into a slab with a thickness of 260mm. The composition is: C0.12%, Si 0.15%, Mn 0.4-0.6%, Cr 2.18%, Mo 1%, Ti 0.03% by weight percentage , P≤0.01%, S≤0.003%, Sn≤0.008%, As≤0.01%, Sb≤0.003%, Pb≤0.01%, N≤0.006%, Fe balance;

[0041] ②Heat the product obtained in step ① to 1200°C, keep it warm for 1.5h, use high-pressure water to remove phosphorus after being released from the furnace, and then carry out two-stage controlled rolling. The rolling is 4 passes, the total reduction rate is 68.85%; the start rolling temperature of the finish rolling is 900°C, the final rolling temperature is 830°C, the rolling is 4 passes, the total reduction rate is 63.75%, and the thickness of 30mm is obtained. steel plate;

[0042] ③The product obtained in step ② is leveled ...

Embodiment 3

[0047] A kind of preparation method of 12Cr2Mo1 hot-rolled container steel plate, described preparation method comprises the steps:

[0048] ①Molten steel is smelted according to the designed composition and continuously cast into a slab with a thickness of 320mm. The composition is: C0.12%, Si 0.15%, Mn 0.4-0.6%, Cr 2.18%, Mo 1%, Ti 0.03% by weight percentage , P≤0.01%, S≤0.003%, Sn≤0.008%, As≤0.01%, Sb≤0.003%, Pb≤0.01%, N≤0.006%, Fe balance;

[0049] ②Heat the product obtained in step ① to 1200°C and keep it warm for 2 hours. 3 passes, the total reduction rate is 57.82%; the start rolling temperature of finish rolling is 880°C, the final rolling temperature is 820°C, the rolling is 3 passes, the total reduction rate is 64.44%, and the 48mm thick steel plate;

[0050] ③The product obtained in step ② is leveled one by one, and after hot rolling, it is cooled to 550°C with water at a cooling rate of 20°C / s, and then air-cooled to room temperature;

[0051] ④Raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com