High-toughness austenite boiler steel

A technology of austenitic and boiler steel, which is applied to high-toughness austenitic boiler steel, manufacturing super-supercritical thermal power unit superheater and reheater tubes, can solve problems such as low impact toughness at room temperature, and achieve high toughness in composition design. , The effect of reasonable composition design and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail with examples below. The examples are only descriptions of the best embodiments of the present invention, and do not limit the scope of the present invention in any way.

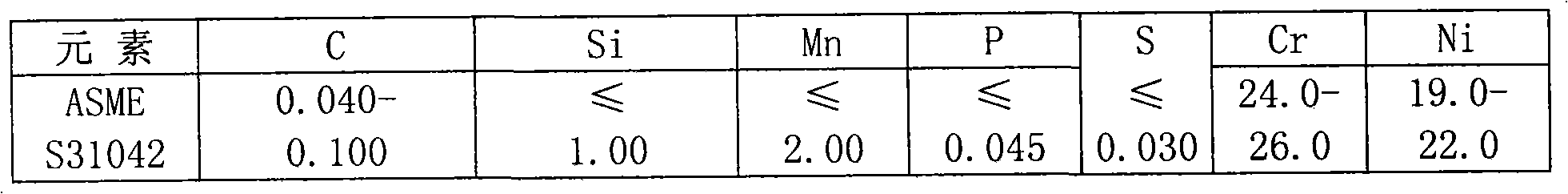

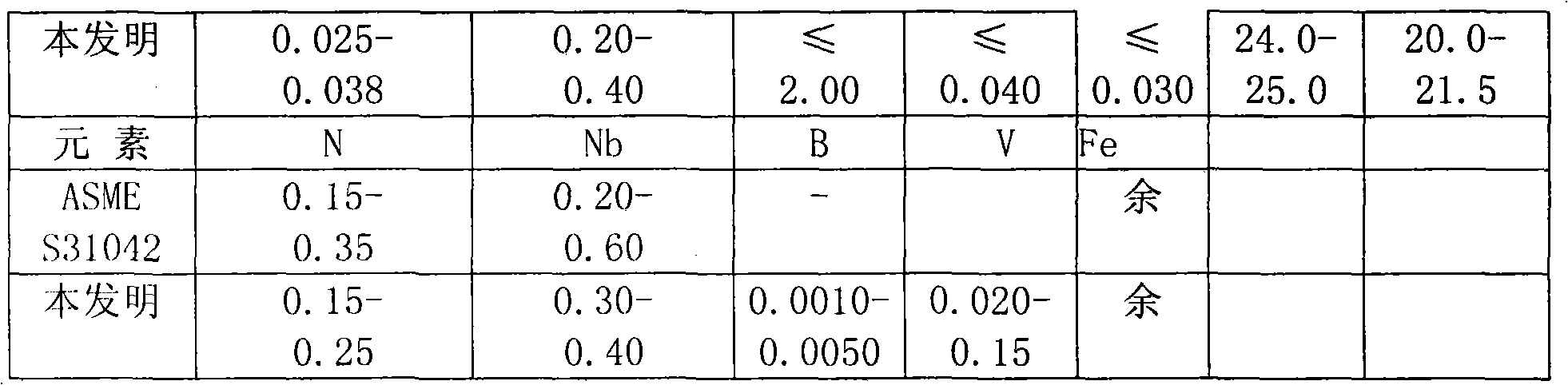

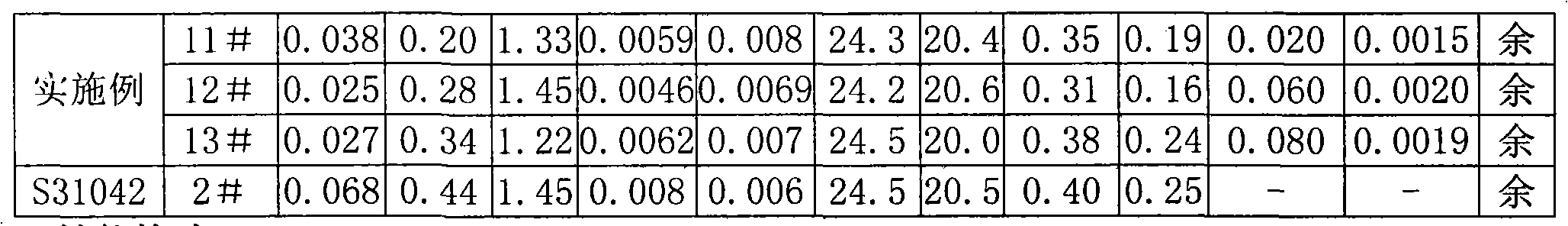

[0029] According to the composition range proposed by the present invention, three groups of embodiments are made on the austenitic heat-resistant steel of the present invention. In order to compare with the examples, we used the same method to prepare a group of comparative examples of S31042 steel. The composition of the heat-resistant steel of the embodiment of the present invention and the composition of the heat-resistant steel of the comparative example are listed in Table 1.

[0030] The steel pipes of the examples and the steel pipes of the comparative examples are prepared according to the same process: raw material preparation→EAF+AOD smelting→die casting→slab opening→hot cutting to length→centering→cross rolling and piercing→cold rolled pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com