Heat treatment technique for additive component

A component and process technology, applied in the field of heat treatment of additive components, can solve the problem that additive components cannot meet the application requirements of key components, and achieve the effect of meeting performance requirements and improving high-temperature durable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

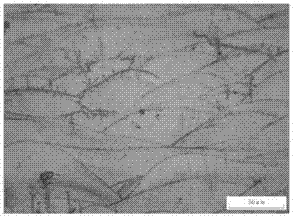

Image

Examples

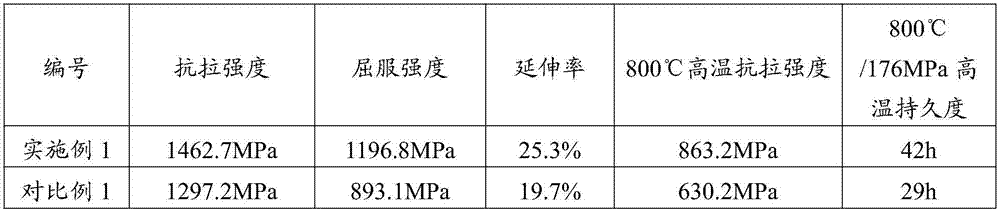

Embodiment 1

[0034] A heat treatment process for additive components provided in Example 1 of the present invention realizes heat treatment of cobalt-chromium-molybdenum alloy additive components, wherein the chemical composition of cobalt-chromium-molybdenum alloy additive components is: Cr: 29.22wt.%, Mo: 6.07wt.%, W: 0.01wt.%, Ni: 0.06wt.%, Fe: 0.18wt.%, C: 0.05wt.%, Si: 0.2wt.%, Mn: 0.47wt.%, S: 0.005 wt.%, P: 0.01 wt.%, Co: Bal.

[0035] A heat treatment process for an additive component provided in Example 1 of the present invention mainly includes the following steps:

[0036] For annealing, heat the cobalt-chromium-molybdenum alloy additive component to 420°C and keep it for 45 minutes, then raise the temperature to 780°C with the furnace and keep it for 1 hour, then cool it to 600°C with the furnace and then air-cool it.

[0037] One-line quenching, heat the cobalt-chromium-molybdenum alloy additive component to 720°C and keep it warm for 10 hours, then water-cool; take out the c...

Embodiment 2

[0054] A heat treatment process for an additive component provided in Embodiment 2 of the present invention mainly includes the following steps:

[0055] For annealing, heat the cobalt-chromium-molybdenum alloy additive component to 420°C and keep it for 45 minutes, then raise the temperature to 780°C with the furnace and keep it for 1 hour, then cool it to 600°C with the furnace and then air-cool it.

[0056] One-line quenching, heat the cobalt-chromium-molybdenum alloy additive component to 780°C and keep it warm for 10 hours, then water-cool; take out the cobalt-chromium-molybdenum alloy additive component after water cooling, heat it up to 1020°C with the furnace again, and keep it warm for 10 hours. 5min, then water cooled.

[0057] Double quenching, heat the cobalt-chromium-molybdenum alloy additive component to 780°C and keep it warm for 10 hours, then water-cool; take out the cobalt-chromium-molybdenum alloy additive component after water cooling, heat it up to 1020 wi...

Embodiment 3

[0073] A heat treatment process for an additive component provided in Example 3 of the present invention realizes heat treatment of a cobalt-chromium-molybdenum alloy additive component, wherein the chemical composition of the cobalt-chromium-molybdenum alloy additive component is: Cr: 29.22wt.%, Mo: 6.07wt.%, W: 0.01wt.%, Ni: 0.06wt.%, Fe: 0.18wt.%, C: 0.05wt.%, Si: 0.2wt.%, Mn: 0.47wt.%, S: 0.005 wt.%, P: 0.01 wt.%, Co: Bal.

[0074] A heat treatment process for an additive component provided in Embodiment 3 of the present invention mainly includes the following steps:

[0075] For annealing, heat the cobalt-chromium-molybdenum alloy additive component to 420°C and keep it for 45 minutes, then raise the temperature to 780°C with the furnace and keep it for 1 hour, then cool it to 600°C with the furnace and then air-cool it.

[0076] One-line quenching, heat the cobalt-chromium-molybdenum alloy additive component to 750°C and keep it warm for 12 hours, then water-cool; take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com