Method for improving room temperature strength and high-temperature performance of Al-Cu-Mg alloy for aluminum alloy drilling rod

An al-cu-mg, high-temperature performance technology is applied in the field of improving the room temperature strength and high-temperature performance of Al-Cu-Mg alloys for aluminum alloy drill pipes, which can solve problems such as increasing costs and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

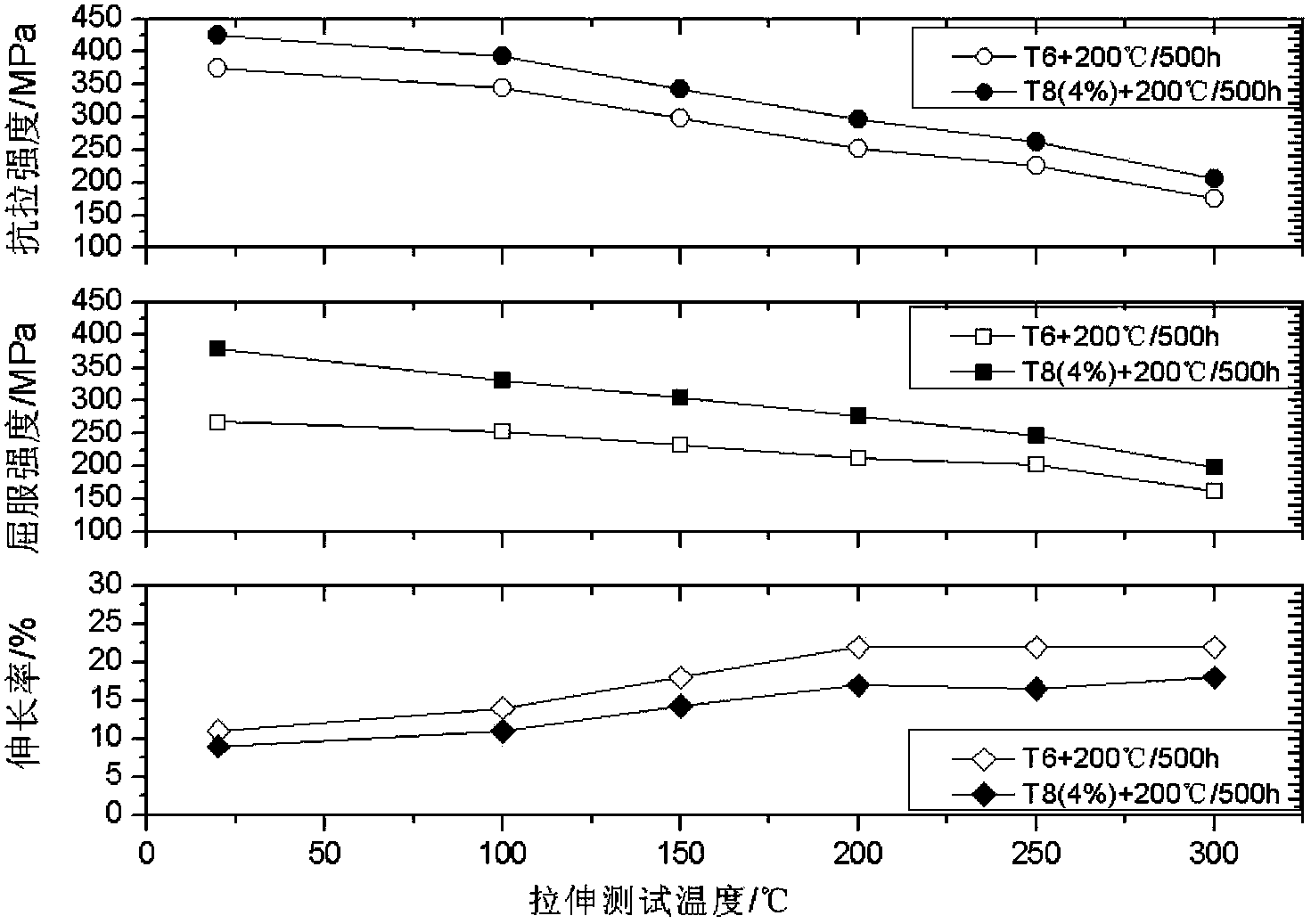

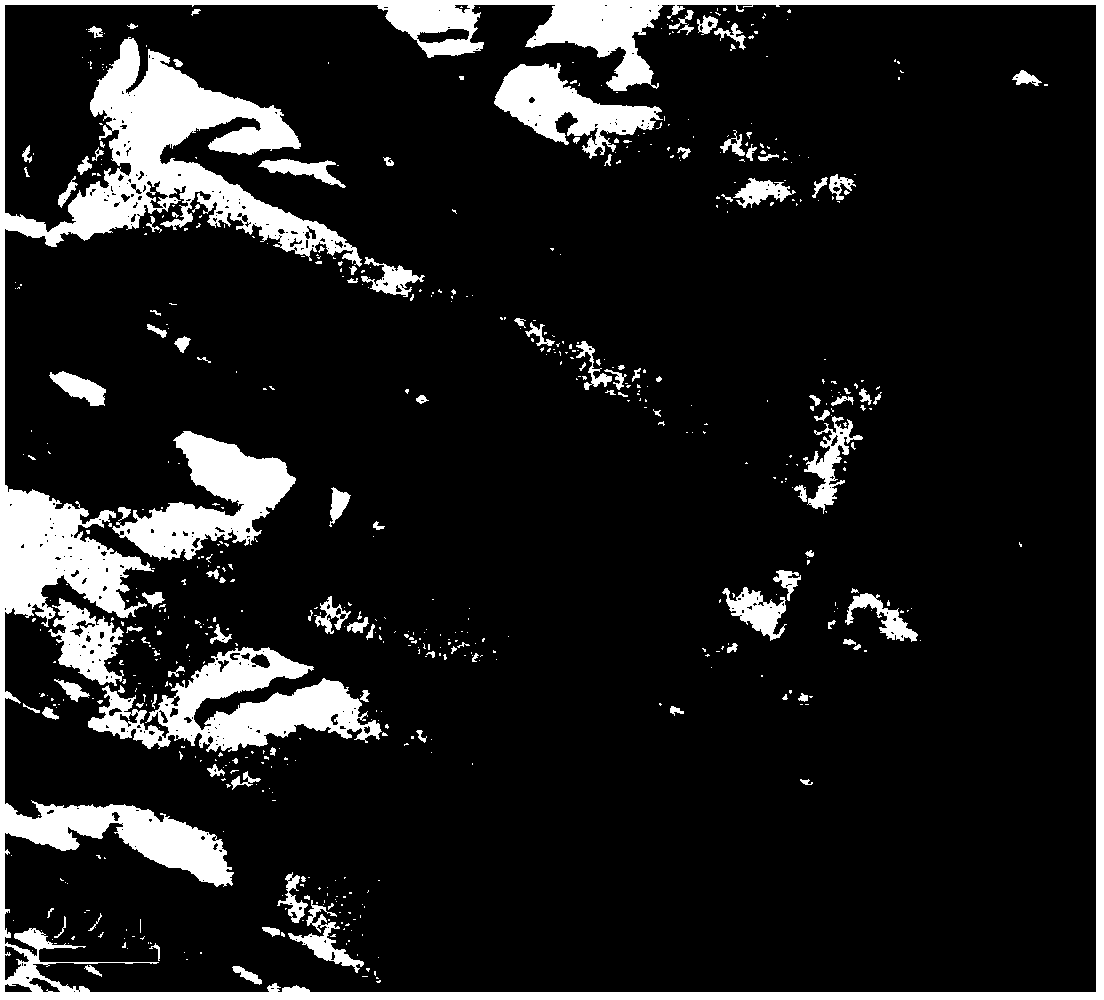

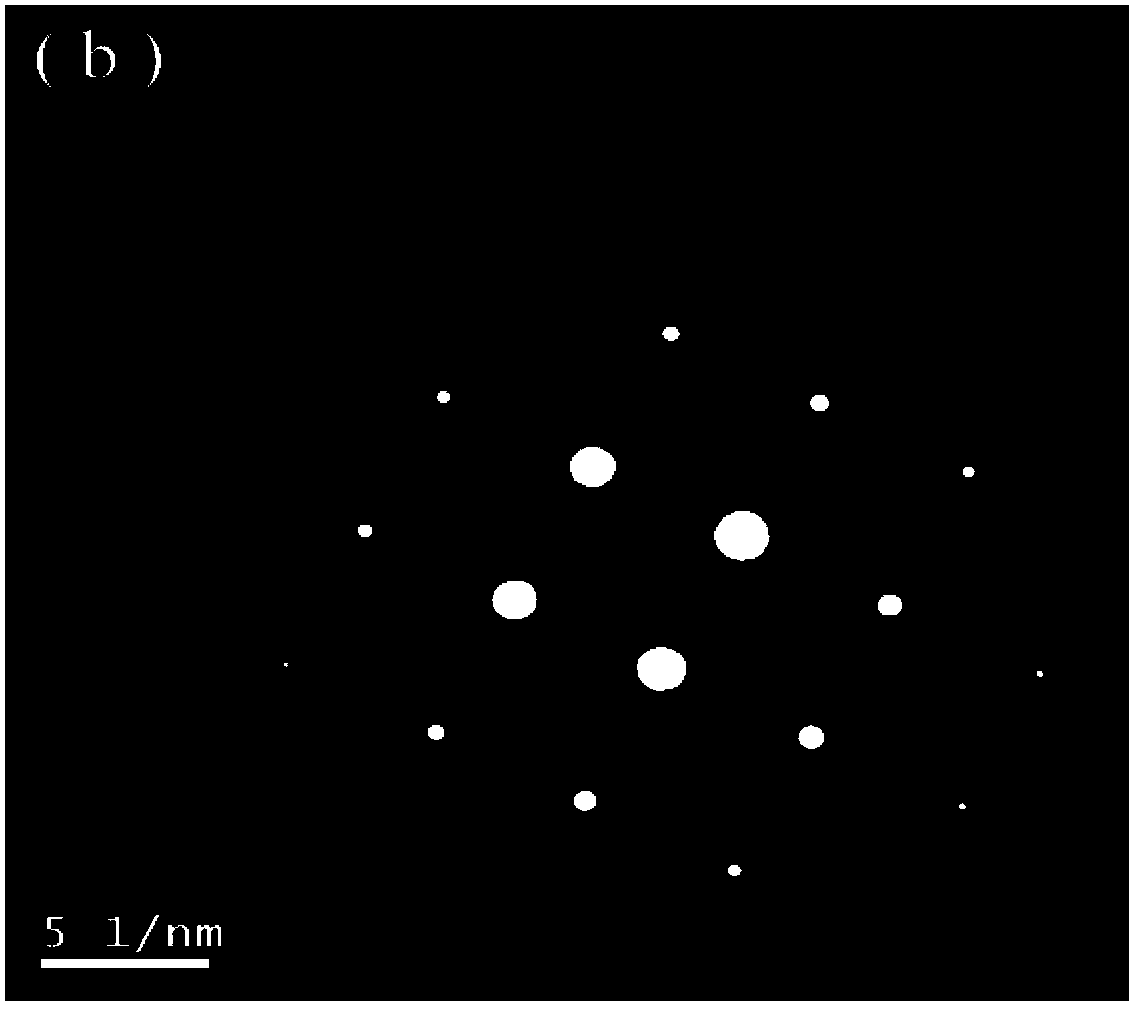

[0047] This example provides a method for improving room temperature strength and high temperature performance of Al-Cu-Mg alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 15 And Table 1, the method includes: after the Al-Cu-Mg alloy that has undergone solid solution is pre-stretched and deformed by 0 to 8%, it is heated to 160°C to 190°C, kept for 4 hours to 120 hours, and then air-cooled, and the Al-Cu - The copper-magnesium content ratio in the Mg alloy is less than or equal to 5. The composition and weight percentage of the Al-Cu-Mg alloy are: Cu: 3.8% to 4.5%, Mg: 1.2% to 1.6%, Mn: 0.3% to 0.9%, Ti: 0.05% to 0.20%, and the balance is Al. The solid solution temperature of the Al-Cu-Mg alloy is 470°C to 500°C. The solid solution time of the Al-Cu-Mg alloy is 50 minutes to 90 minutes. The Al-Cu-Mg alloy is cooled by water quenching after solid solution. The Al-Cu-Mg alloy obtains more S' strengthening phase structure dispersed and precip...

Embodiment 2

[0049] The embodiment of the present invention provides a method for improving the room-temperature strength and high-temperature performance of Al-Cu-Mg alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 15 And Table 1, the method includes: after the Al-Cu-Mg alloy that has undergone solid solution is pre-stretched and deformed by 0 to 8%, it is heated to 160°C to 190°C, kept for 4 hours to 120 hours, and then air-cooled, and the Al-Cu - The copper-magnesium content ratio in the Mg alloy is less than or equal to 5. The composition and weight percentage of the Al-Cu-Mg alloy are: Cu: 4.0% to 4.3%, Mg: 1.5% to 1.6%, Mn: 0.4% to 0.6%, Ti: 0.1% to 0.15%, and the balance is Al. Wherein, the solid solution temperature of the Al-Cu-Mg alloy is 450°C to 500°C. The solid solution time of the Al-Cu-Mg alloy is 60 minutes to 90 minutes. Al-Cu-Mg alloy is cooled by water quenching after solid solution.

Embodiment 3

[0051] The embodiment of the present invention provides a method for improving the room-temperature strength and high-temperature performance of Al-Cu-Mg alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 15 And Table 1, the composition of the Al-Cu-Mg alloy and the percentage by weight of each composition are: 4.0% Cu, 1.2% Mg, 0.6% Mn, 0.2% Ti, and the balance is Al. The aluminum alloy sheet of this composition is solid-dissolved at 500°C for 1 hour and quenched in water, the pre-stretch deformation is 0%, and the tensile mechanical properties at room temperature after aging at 160°C for 120 hours reach: the tensile strength is 500MPa, the yield strength It is 367MPa, and the elongation is 17%; the high-temperature tensile performance at 200°C reaches: the tensile strength is 386MPa, the yield strength is 314MPa, and the elongation is 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com