A kind of high damage resistance aluminum alloy and preparation method thereof

An aluminum alloy, damage-resistant technology, applied in the field of non-ferrous metal materials, can solve problems such as narrow PFZ, and achieve the effect of improving damage resistance, high yield strength, and high fatigue crack growth resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

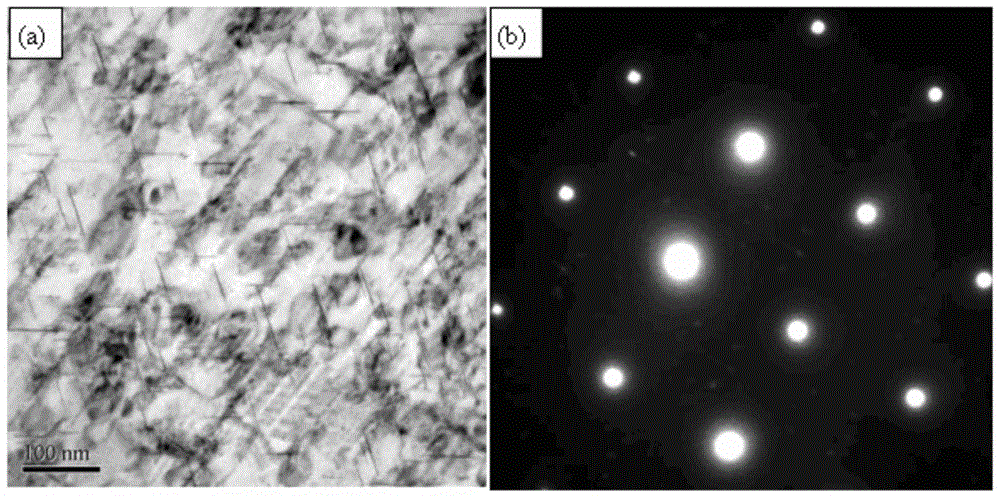

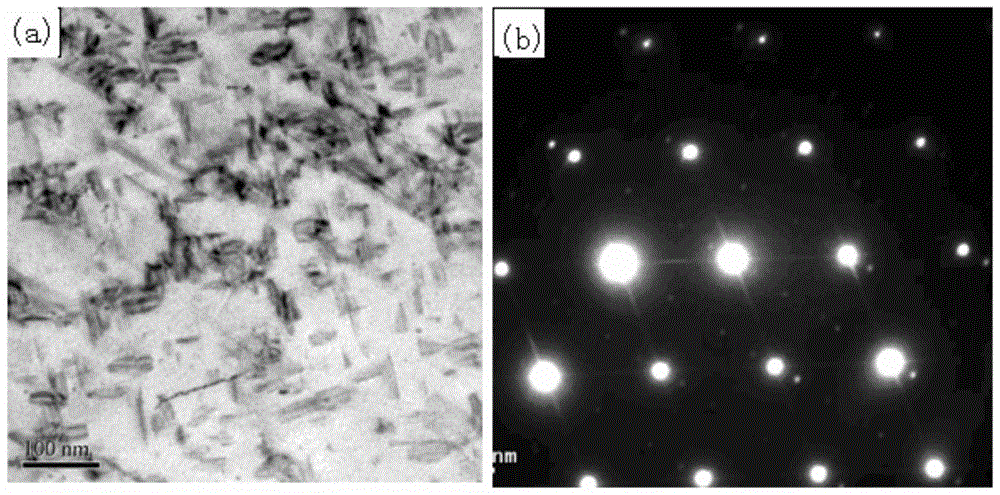

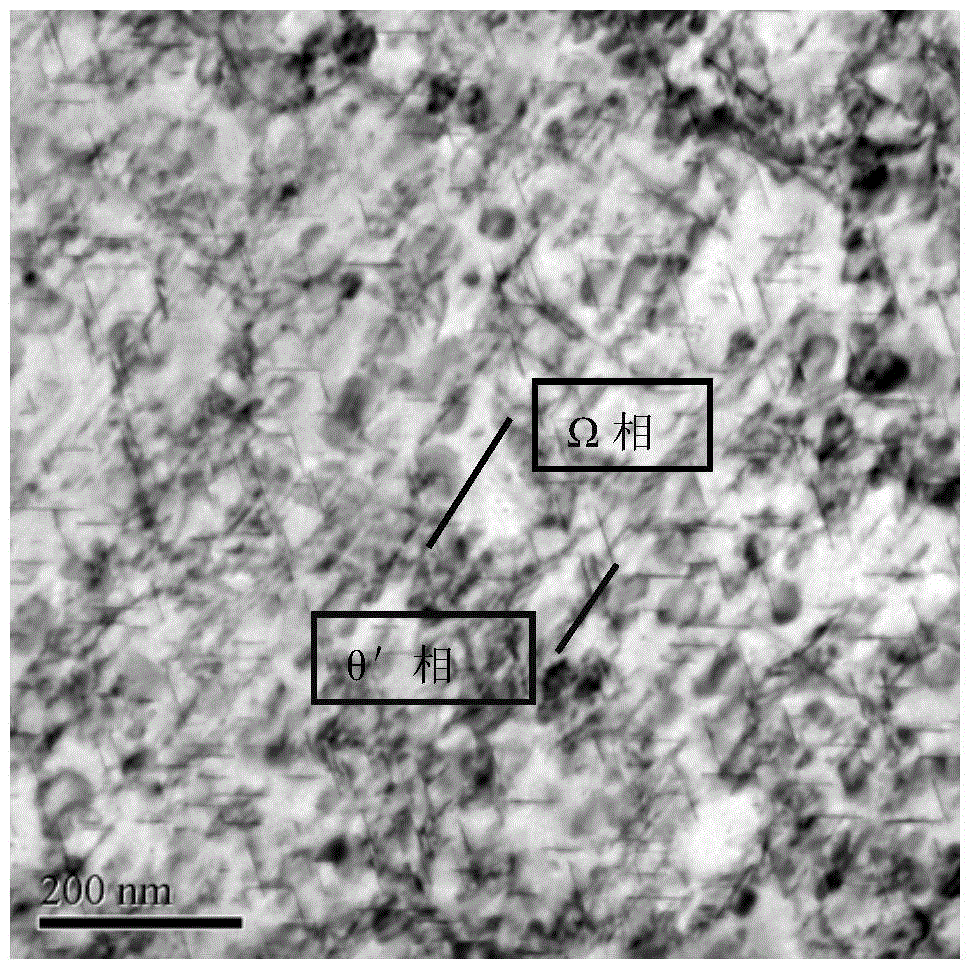

Image

Examples

Embodiment example 1

[0050] The composition of alloy 1 is 3.15% Cu, 0.84% Mg, 0.3% Mn, 0.48% Ag, 0.12% Zr, and the balance is unavoidable trace impurity elements and Al.

[0051] After the ingot billet is obtained, it is first kept at 480°C for 8 hours, and then at 520°C for 36 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 15%; the total deformation of the hot rolling is 60%; the system of the intermediate annealing is: after annealing at 450 ℃ for 5 hours Cool to room temperature with the furnace; the pass deformation of the cold rolling is 10%, and the total deformation of the cold rolling is 60%.

[0052] The cold-rolled sheet is solution treated at 530°C for one hour, water quenched, and then pre-deformed by 4% cold rolling, aged at room temperature for 100 days, and the mechanical properties at room...

Embodiment example 2

[0055] The composition of alloy 1 is 3.15% Cu, 0.84% Mg, 0.3% Mn, 0.48% Ag, 0.12% Zr, and the balance is unavoidable trace impurity elements and Al.

[0056] After the ingot billet is obtained, it is first kept at 480°C for 8 hours, and then at 520°C for 36 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 15%; the total deformation of the hot rolling is 60%; the system of the intermediate annealing is: after annealing at 450 ℃ for 5 hours Cool to room temperature with the furnace; the pass deformation of the cold rolling is 10%, and the total deformation of the cold rolling is 60%.

[0057] The cold-rolled sheet is solution treated at 520°C for 1.5 hours, water quenched, and then subjected to 4% cold rolling pre-deformation, and artificially aged at 145°C for 60 hours to obtain mechanic...

Embodiment example 3

[0065]The composition of alloy 2 is 3.32% Cu, 0.91% Mg, 0.3% Mn, 0.48% Ag, 0.1% Zr, and the balance is unavoidable trace impurity elements and Al. After the ingot billet is obtained, it is first kept at 485°C for 12 hours, and then at 530°C for 30 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 8%; the total deformation of the hot rolling is 64%; the system of the intermediate annealing is: after annealing at 420 ℃ for 4h Cool to room temperature with the furnace; the deformation of each pass of cold rolling is 8%, and the total deformation of cold rolling is 64%.

[0066] The cold-rolled sheet is solution treated at 530°C for one hour, water quenched, and then pre-deformed by 4% cold rolling, aged at room temperature for 100 days, and the mechanical properties at room temperature are ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com