Spray heat treatment method for large titanium alloy components

A heat treatment method and titanium alloy technology, applied in the field of titanium alloy, can solve the problems of large thickness difference, low thermal conductivity of titanium alloy, large difference in sample structure and performance, etc., and achieve high uniformity and high resistance to fatigue crack growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

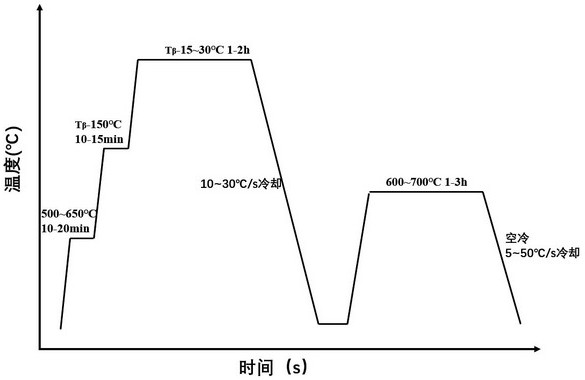

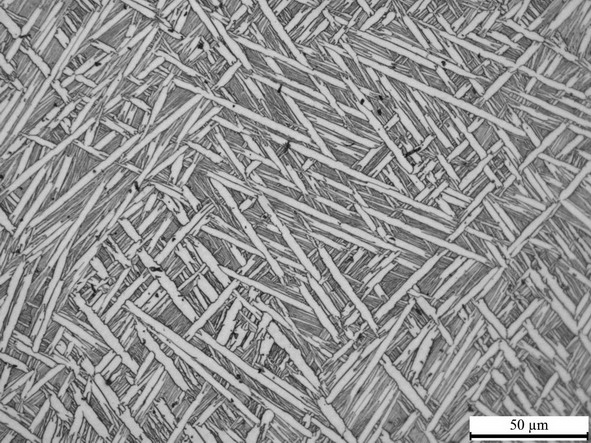

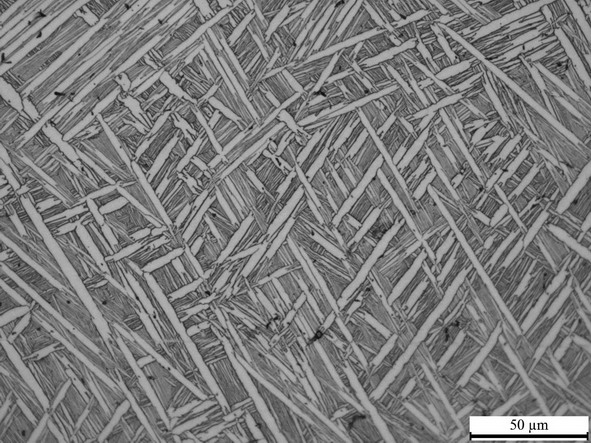

[0030] For the large aircraft structural parts of TA15 titanium alloy with a mesh basket structure after laser additive manufacturing, the phase transition point was tested by metallographic method, and the phase transition point was 995 ℃, and then the same heat treatment furnace was used to heat it to 975 ℃ for 1 Then, the sample was taken out of the heat treatment furnace and air-cooled for 60 seconds. The components mainly have three cross-sectional thicknesses, 30mm, 60mm and 120mm, respectively. The nozzle with an inner diameter of 15mm is selected, and the water flow rate Q is selected respectively. 1 It is 0.18 liters / second, 0.72 liters / second and 2.88 liters / second, and the spray time is 18 seconds, 36 seconds and 72 seconds respectively. Then increase the flow rate, Q 2 Select 0.36 liter / sec, 1.44 liter / sec, and 5.76 liter / sec, respectively, and cool to room temperature. Then, the component was heated to 670°C, kept for 2 hours, and then cooled to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com