Motor with internal evaporative cooling system

A technology of evaporative cooling and cooling liquid, which is applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., and can solve the problems of high manufacturing cost and maintenance cost, many supporting equipment, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

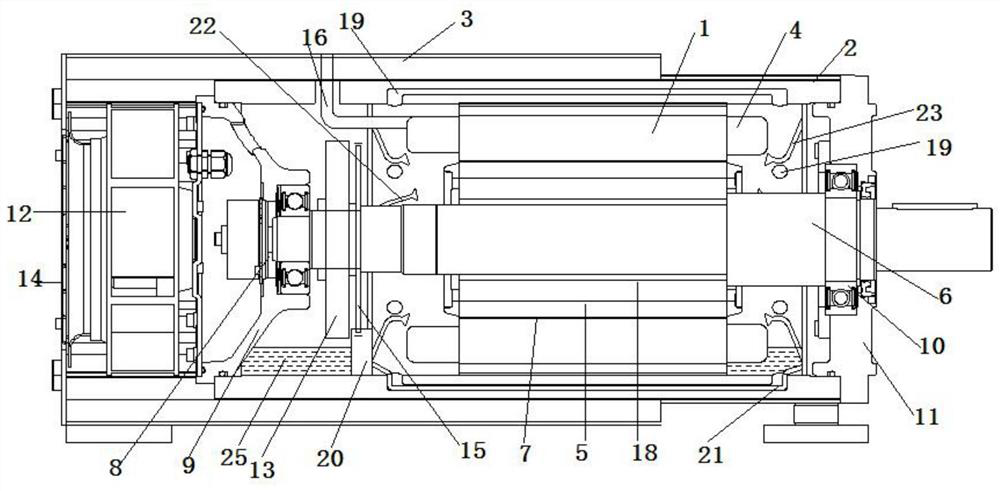

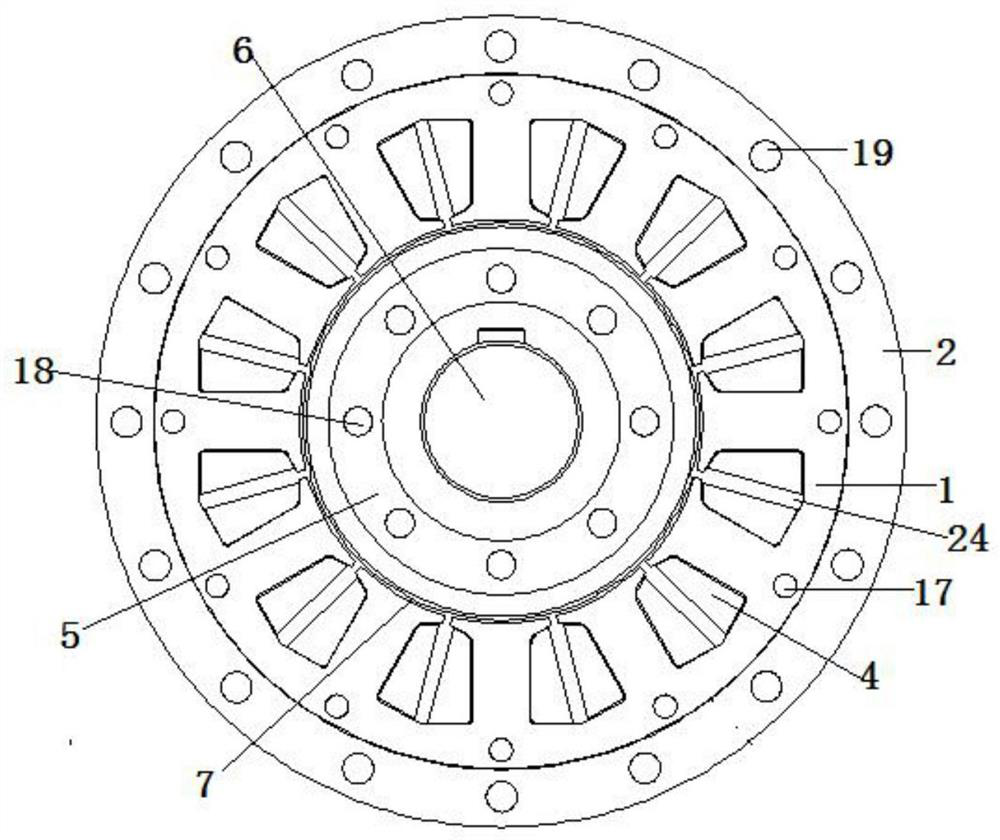

[0017]Such asfigure 1 withfigure 2A motor having an internal evaporation cooling system comprises a stator 1, the stator 1 is fixed inside the housing 2, the outer casing of the housing 2 with a cooling housing 3, and the stator 1 is inserted inside. The winding 4 is provided with a rotor 5, and the rotor 5 is attached to the rotating shaft 6, and the rotor 5 is provided with a gas gap 7 between the stator 1, the rotor 6 connects the bearing housing 8, the bearing housing 8 through The bearing bracket 9 is fixed to the inner wall of the housing 2, and the rotating shaft 6 connects the bearing seat I10, the bearing housing I10, in the right end cover 11, the right end cover 11 seals the housing 2 right end, the bearing housing 8 The motor fan 12 and the driving fan 13 are respectively provided on the left and right sides, the motor fan 12 connected to the left end cover 14, located on the left side of the bearing bracket 9, the motor fan 12 can heat the stator 1 and the rotor 5, the ...

Embodiment 2

[0019]Such asfigure 1 withfigure 2A motor having an internal evaporation cooling system comprises a stator 1, the stator 1 is fixed inside the housing 2, the outer casing of the housing 2 with a cooling housing 3, and the stator 1 is inserted inside. The winding 4 is provided with a rotor 5, and the rotor 5 is attached to the rotating shaft 6, and the rotor 5 is provided with a gas gap 7 between the stator 1, the rotor 6 connects the bearing housing 8, the bearing housing 8 through The bearing bracket 9 is fixed to the inner wall of the housing 2, and the rotating shaft 6 connects the bearing seat I10, the bearing housing I10, in the right end cover 11, the right end cover 11 seals the housing 2 right end, the bearing housing 8 The motor fan 12 and the driving fan 13 are respectively provided on the left and right sides, the motor fan 12 connected to the left end cover 14, located on the left side of the bearing bracket 9, the motor fan 12 can heat the stator 1 and the rotor 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com