Patents

Literature

42results about How to "Uniform heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

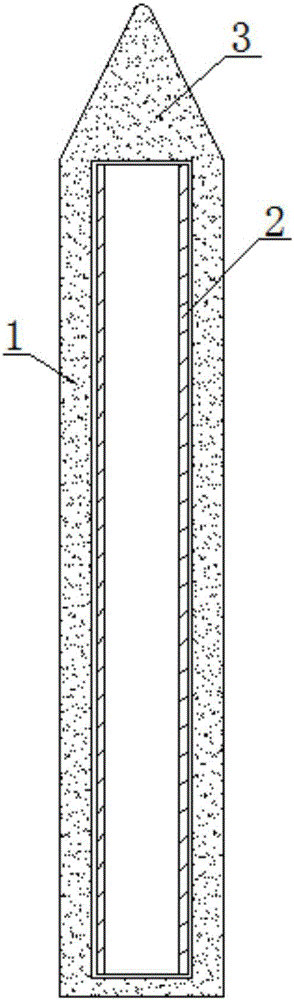

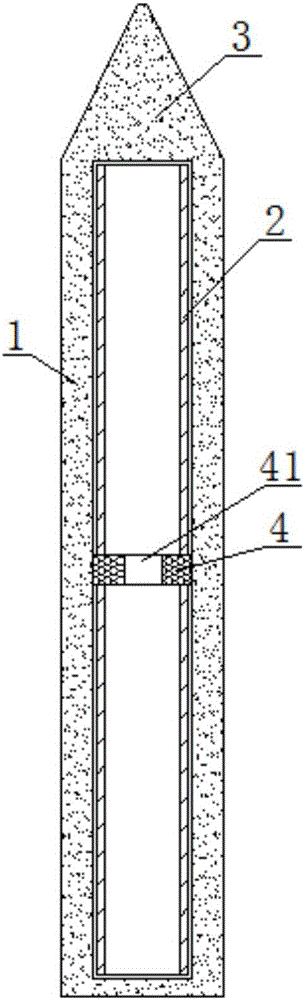

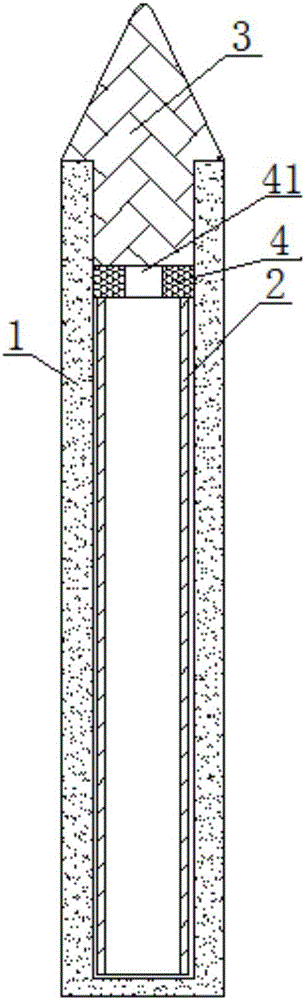

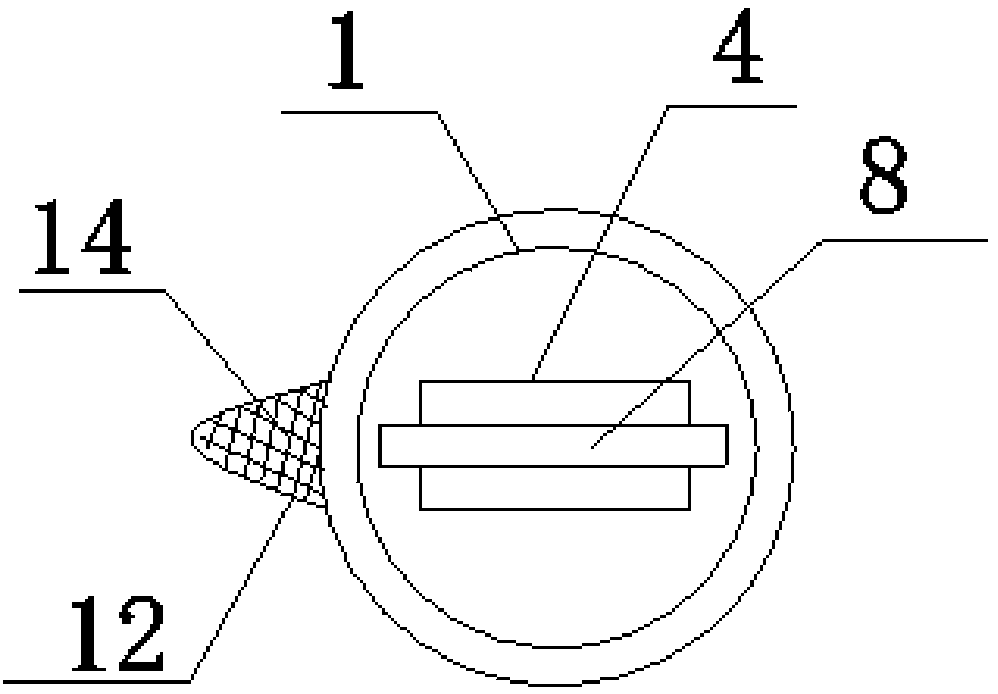

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

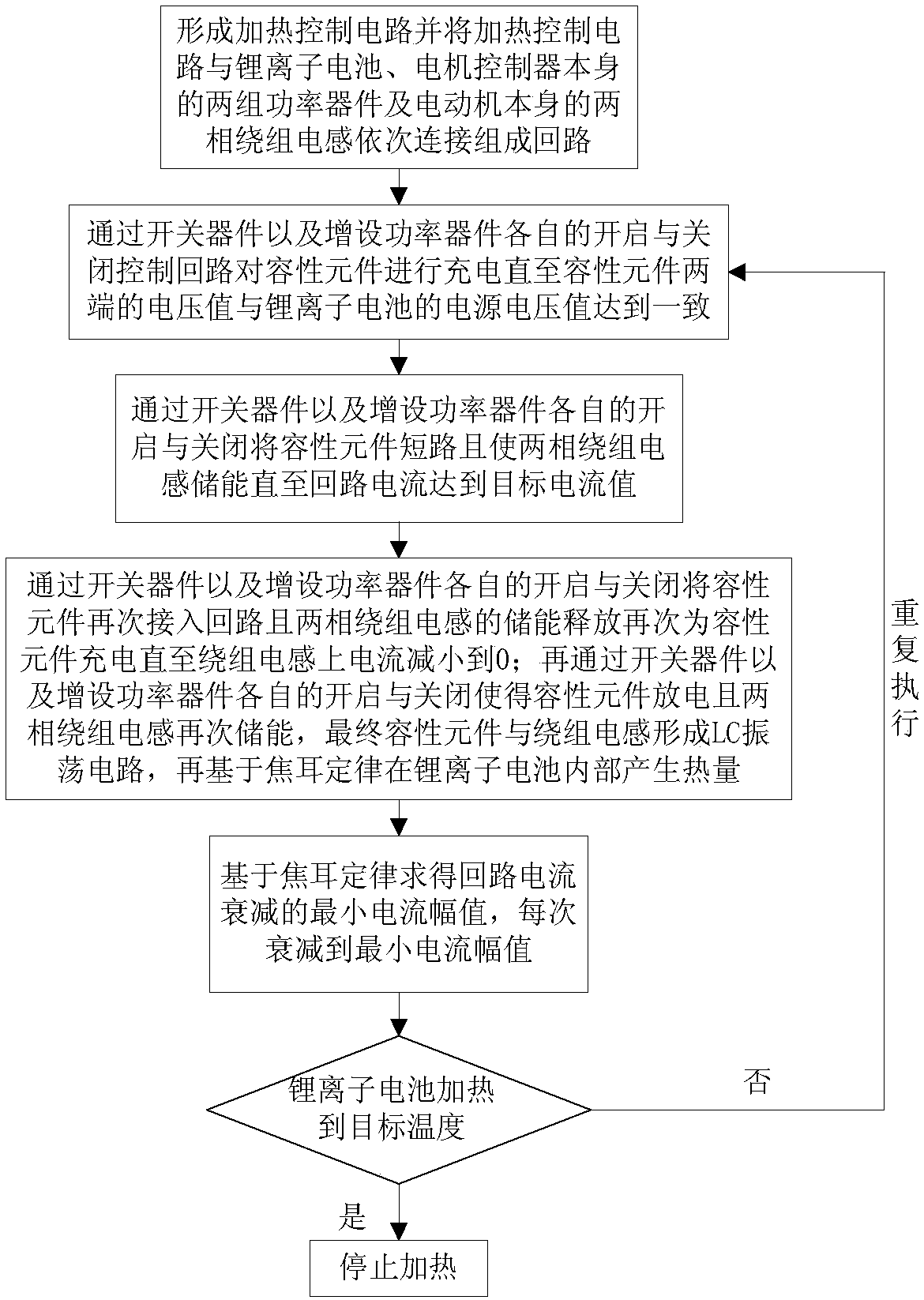

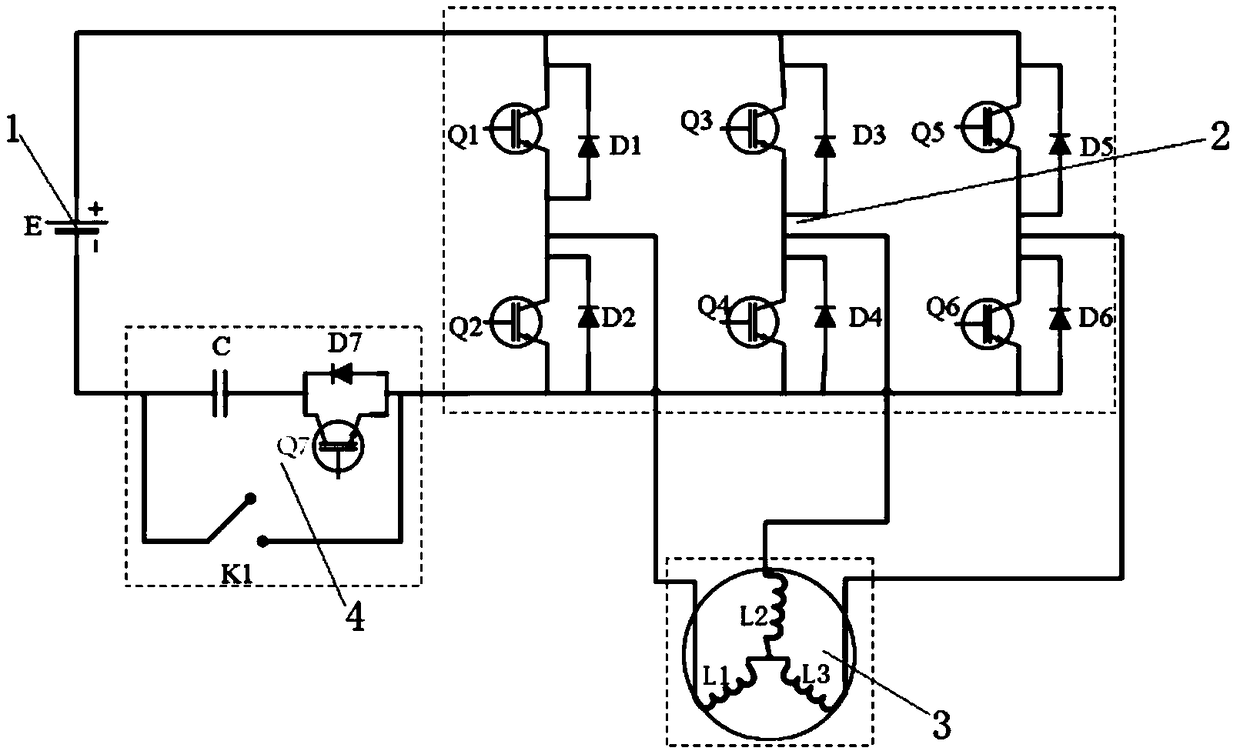

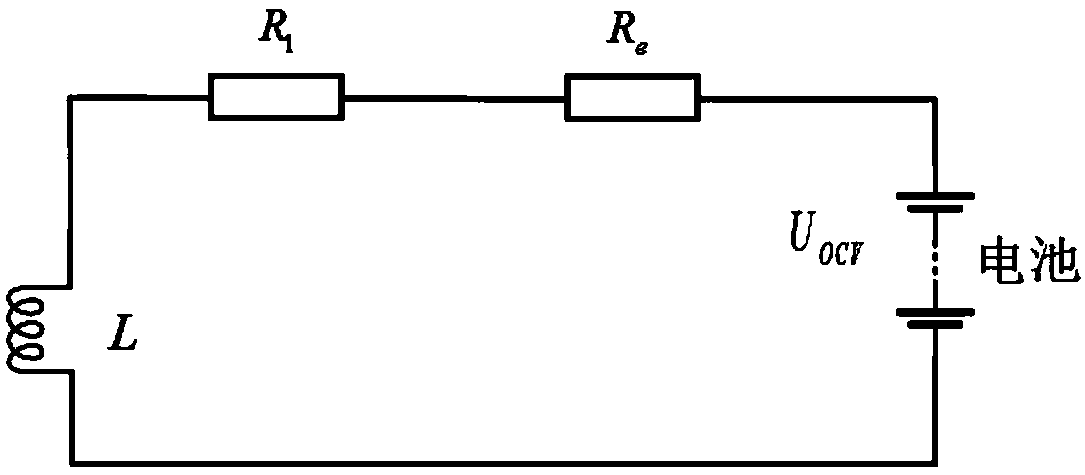

Low-temperature heating control method for lithium ion battery

ActiveCN108847513ASolve the problem of poor charge and discharge performanceExtended service lifeSecondary cellsVehicular energy storageElectrical batterySimple component

A low-temperature heating control method for a lithium ion battery includes the following steps: first selecting a capacitive component; connecting the capacitive component and an additional power device in series, and then connecting a switch device in parallel to form a heating control circuit; then sequentially connecting the heating control circuit with the lithium ion battery, two sets of power devices of a motor controller body, and two-phase winding inductance of a electromotor to form a loop; and controlling charge and discharge of the capacitive component and magnetic energy storage and release of the two-phase winding inductance by opening and closing of the switch device and the additional power device to enable an LC oscillating circuit to be formed between the capacitive element and the winding inductance, generating a high-frequency alternating current, generating heat inside the lithium ion battery based on a joule law, and allowing to repeatedly operating the heating process to achieve continuous oscillation and continuous heat production until heating the lithium ion battery to a target temperature. The low-temperature heating control method for the lithium ion battery can be achieved by only adding a simple component to an inherent structure of an electric vehicle, and has the characteristics of good heating effect, high thermal efficiency and low usage cost.

Owner:BEIHANG UNIV

Method for processing crisp-fried barking walnut kernel

The invention relates to the food processing field, specifically a processing method of a crispy peel free walnut kernel, which solves the problem that color, taste and nutritional components of walnut kernel are damaged in prior art of walnut kernel processing method, comprising the steps of (1) peeling off the walnut kernel; (2) drying: adjusting temperature of the microwave oven at 75 deg C to 85 deg C, baking 2min to 3min; (3) coating: coating the surface of the walnut kernel evenly by constant temperature liquid flavoring; (4) roasting: adjusting temperature of the microwave oven at 115 deg C to 125 deg C, baking 1.5min to 3.5min; it is appropriate when the walnut kernel observed is golden, then cooling the walnut kernel at constant temperature to prepare the crispy peel free walnut kernel. The walnut kernel is processed respectively before and after coating by microwave oven at low temperature, which enables the walnut kernel to be crispy in mouthfeel, bright in color and great preservation of the nutritional components. The peel off of the walnut kernel is dipped by low temperature, low concentration sodium hydroxide solution that is changed always, then neutralized by citric acid, finally washed to remove the peel of the walnut kernel.

Owner:王晶平

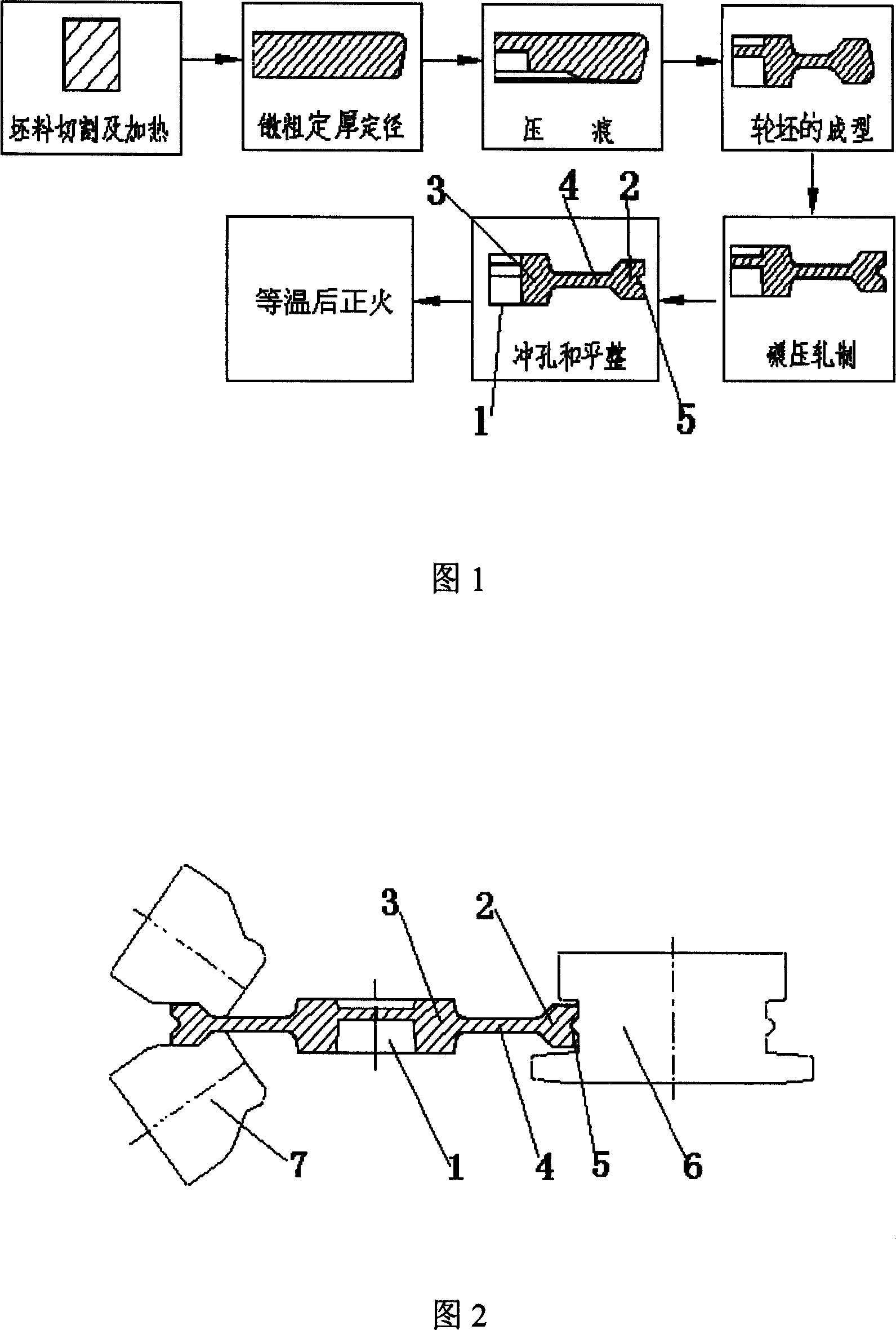

Forging and rolling technology and hot rolling and forging apparatus for making large pulley

ActiveCN101020287AHigh mechanical strengthImprove wear resistancePortable liftingFurnace typesHigh wear resistanceUltimate tensile strength

The present invention discloses forging and rolling technology for large pulley. The forging and rolling process includes hot forging and upsetting steel blank to the required thickness and diameter, die forging to form the hub and spokes, and hot rolling to form the inner circular surface, end surfaces, outer circular surface and slot in circumference of the rim. The present invention also provides the corresponding hot rolling apparatus. The present invention can obtain pulley with high strength, high wear resistance, small internal stress, less deformation and other advantages.

Owner:MAANSHAN IRON & STEEL CO LTD

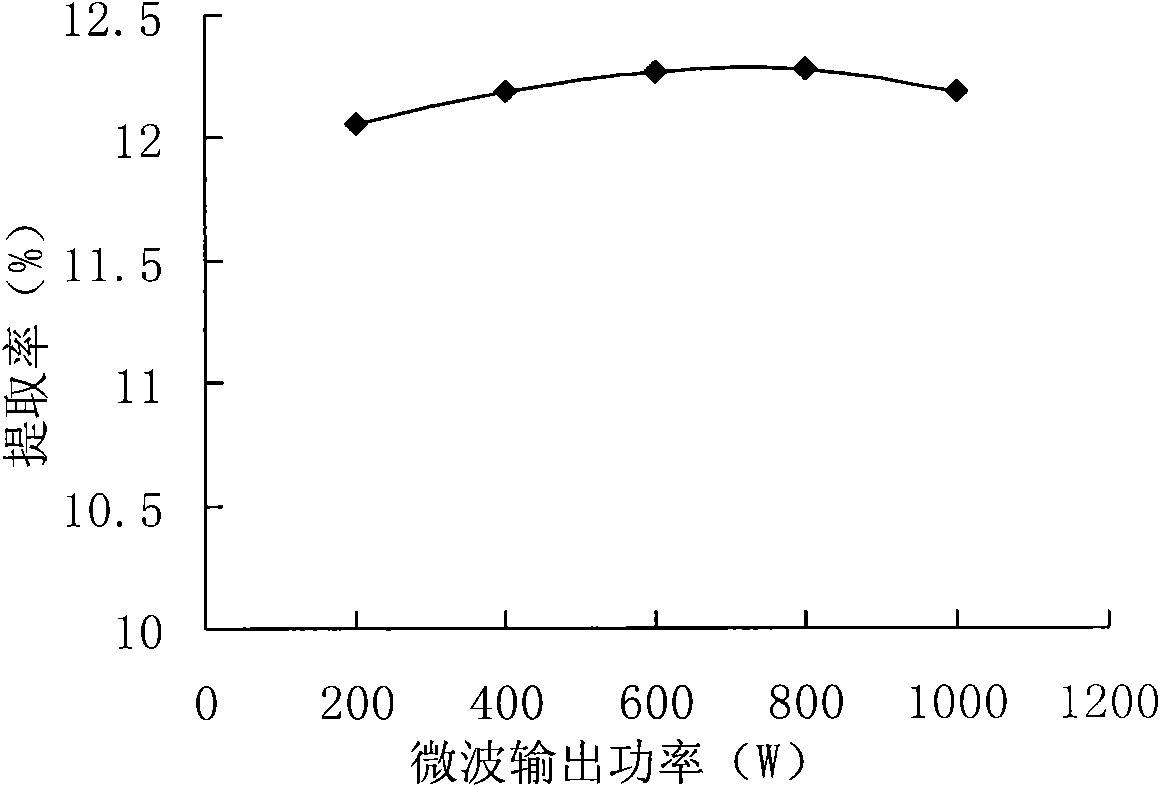

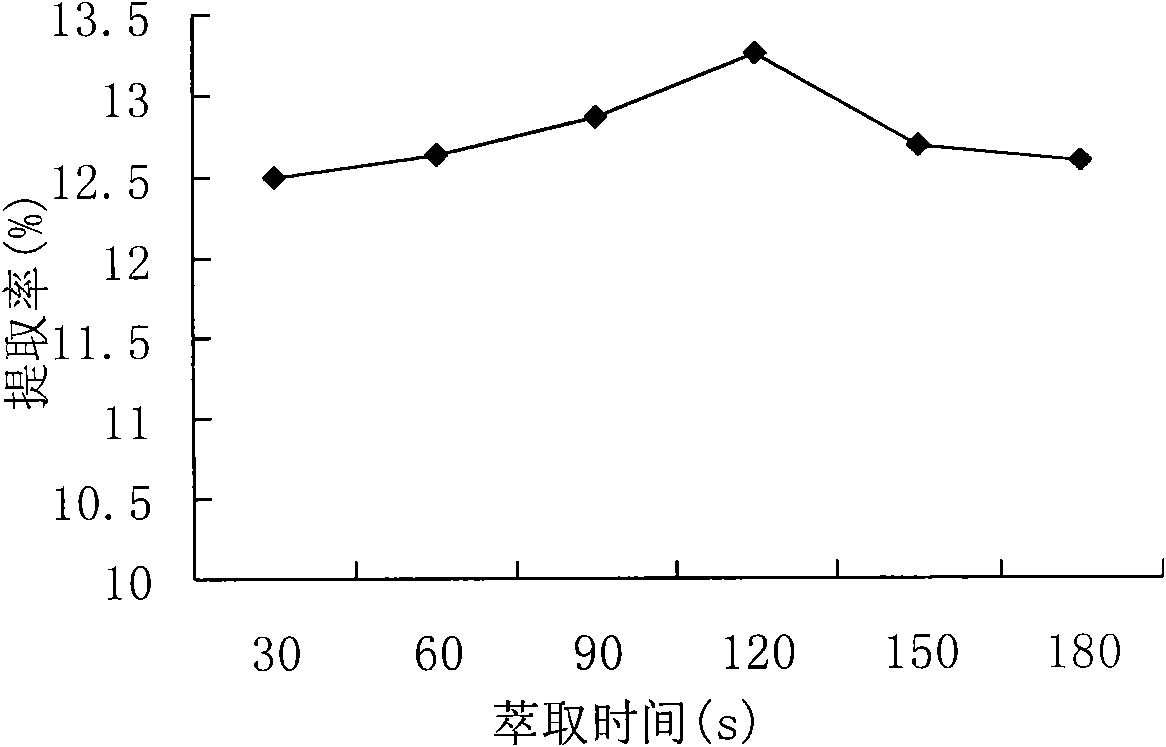

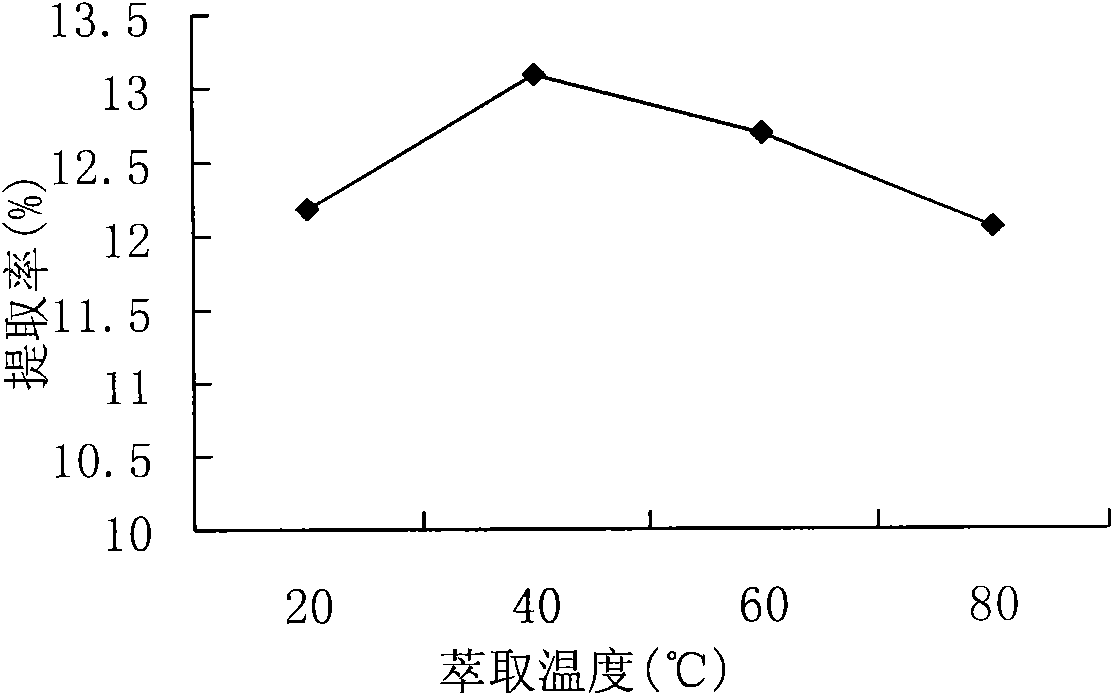

Method for extracting proanthocyanidin from peanut coats

InactiveCN101624388AEasy extractionHigh yieldOrganic chemistryAntinoxious agentsWater bathsMicrowave

The invention discloses a method for extracting proanthocyanidin from peanut coats, comprising the following steps: heating a solvent and a substrate by using a polarization rotation function of microwaves; and extracting proanthocyanidin from peanut coats. The method for extracting proanthocyanidin from peanut coats uses a modern high and new technology, namely a microwave extracting technology to replace the traditional water bath heating extraction, thereby greatly reducing extracting time, increasing extraction efficiency, achieving high speed, high efficiency and safety and becoming more suitable for large-scale industrial production.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

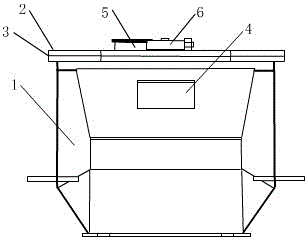

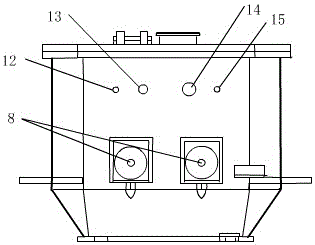

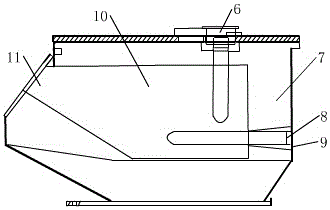

Inert gas shielding immersion type heating difunctional low-pressure casting furnace

The invention provides an inert gas shielding immersion type heating difunctional low-pressure casting furnace. A lining of an aluminum melting pool consists of a high nitrogen composite ceramic brick, a light mass thermal insulation layer, a thermal insulation material and a thermal insulation composite material; an immersion type heater and an immersion type heater adopt heating elements formed by mounting resistance wires in silicon nitride ceramic pipes; the immersion type heater is inserted in the aluminum melting pool from the upper end of a furnace cover, and the immersion type heater is directly immersed in the aluminum melting pool from the external of a furnace shell to realize dual heating; an intake port is connected with a compressed preheated inert gas generation device, and an exhaust port is connected with a gas recovery device; a liquid rise pipe and the immersion type heater are immersed in molten aluminum; two immersion type heaters are mounted at the bottom of the aluminum melting pool; and the lower end of the liquid rise pipe is higher than the immersion type heaters at the bottom. The inert gas shielding immersion type heating difunctional low-pressure casting furnace is uniform in heating speed, high in heat efficiency, low in energy consumption and excellent in thermal shock property, saves the cost, and is suitable for serving as an aluminum alloy casting furnace for use.

Owner:LIAONING YIFEI TECH +1

Automobile expansion tank pressure relief cover reliability test method and system

InactiveCN104458278AAccurate measurementIntuitive processVehicle testingExpansion tankProgrammable logic controller

Owner:SHANDONG HUA TONG AUTOMOBILE MOLDS PLASTICS TECH

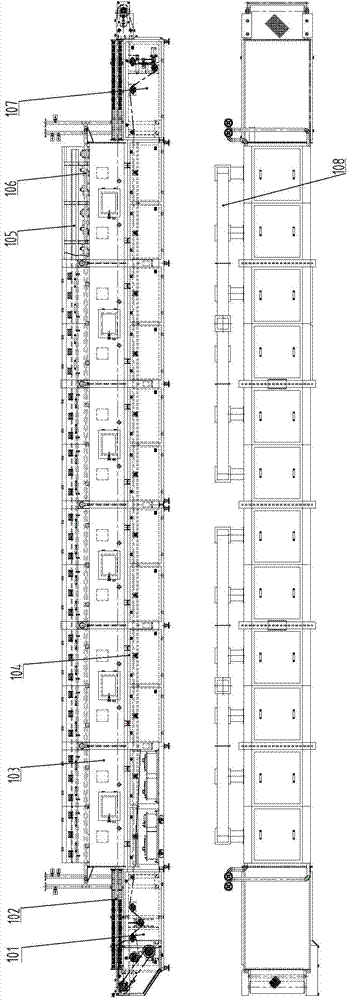

Ultrathin piece material microwave drying device

InactiveCN104748528AUniform heating temperatureNo harmDrying solid materials with heatDrying machines with progressive movementsProduction lineMicrowave

The invention discloses a ultrathin piece material microwave drying device. The ultrathin piece material microwave drying device comprises a frame, wherein a microwave inhibitor and a heating device are mounted on the frame; the microwave inhibitor is connected with the heating device; a wave guider is mounted on the heating device; and a microwave magnetron is mounted on the wave guider. The frame comprises a back frame, a middle frame and a front frame connected in sequence, wherein microwave inhibitors are respectively mounted on the back frame and the front frame; a heating device is mounted on the middle frame; and the microwave inhibitors are connected to the two ends of the heating device. The ultrathin piece material microwave drying device can be specifically applied to a rolling method slice production line to dry rolled wet slices as dry slices with stated water content, and can be applied to high-speed drying places of other ultrathin piece materials.

Owner:YICHANG BAOXING TECH IND DEVCO LTD

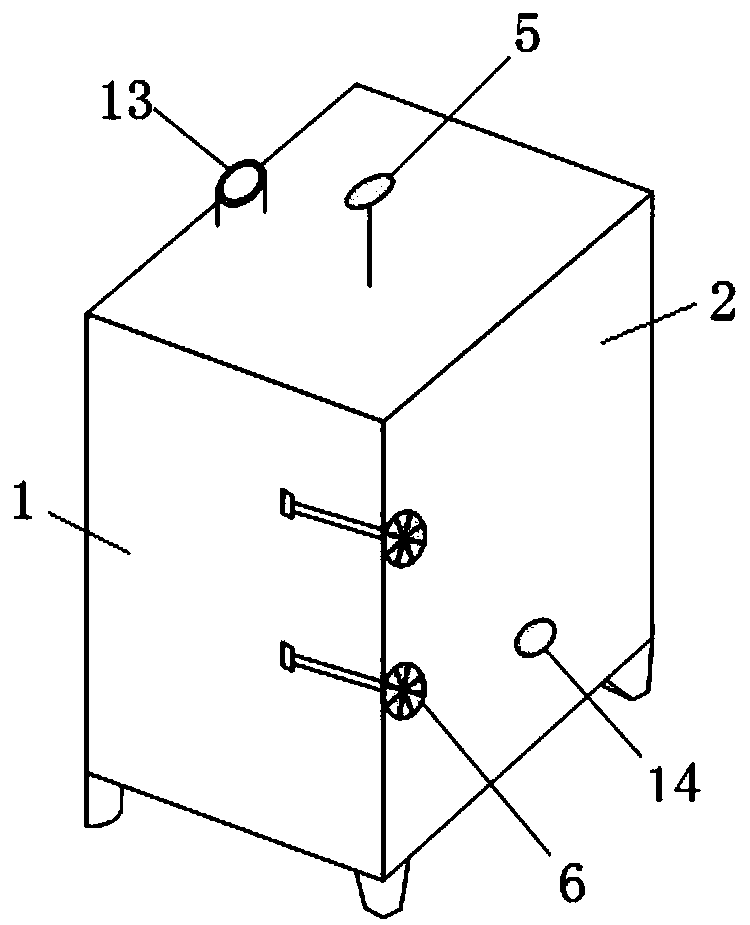

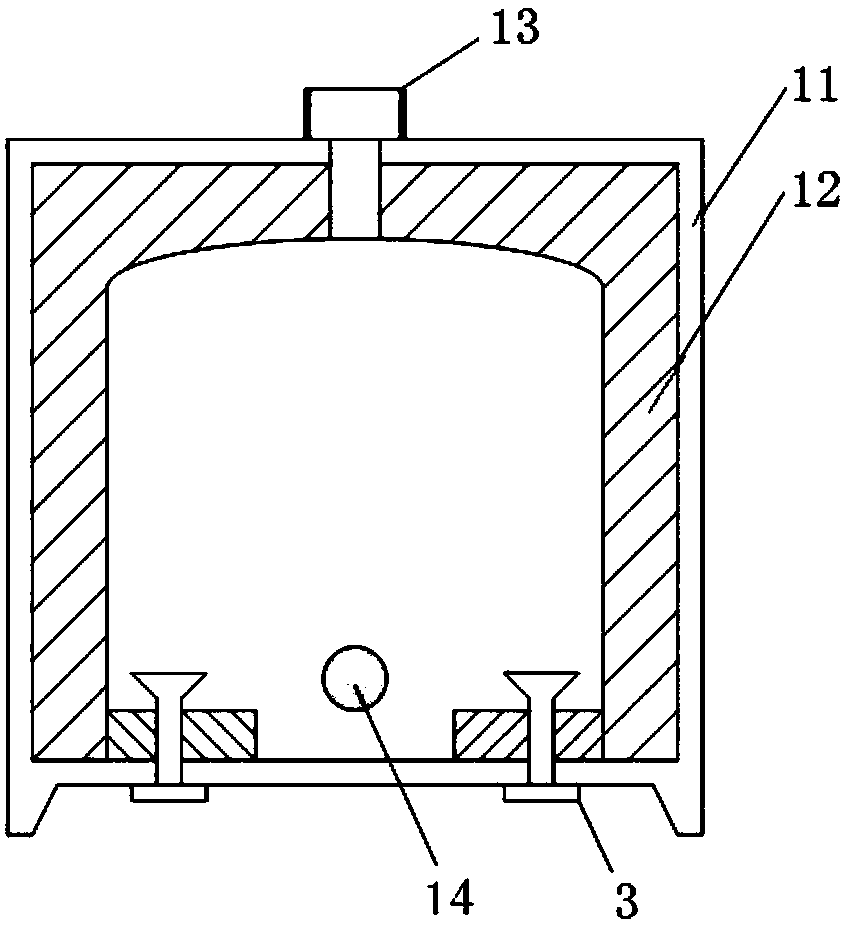

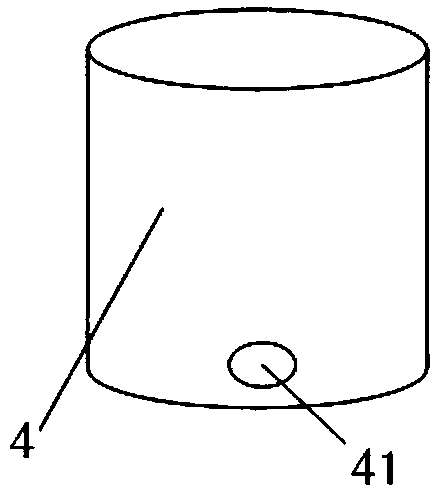

Polymer reactor with novel structure

ActiveCN101829533AUniform cooling rateUniform heating rateChemical/physical/physico-chemical stationary reactorsBody positionsEngineering

Owner:ZHENHAI PETROCHEM JIANAN ENG

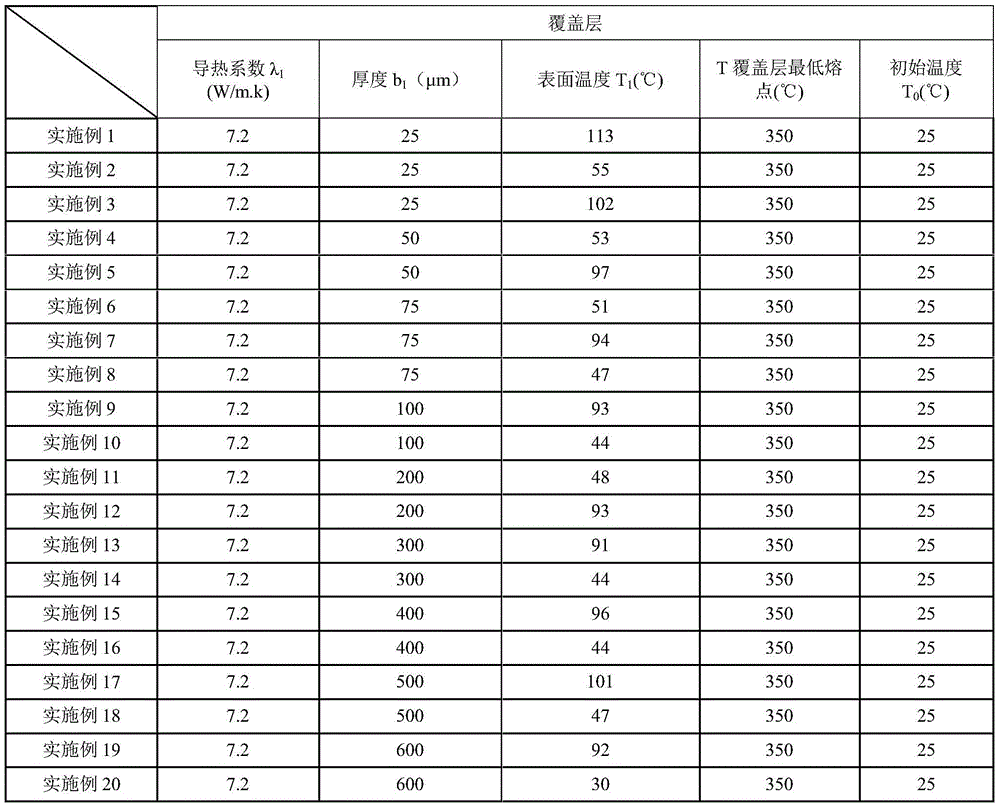

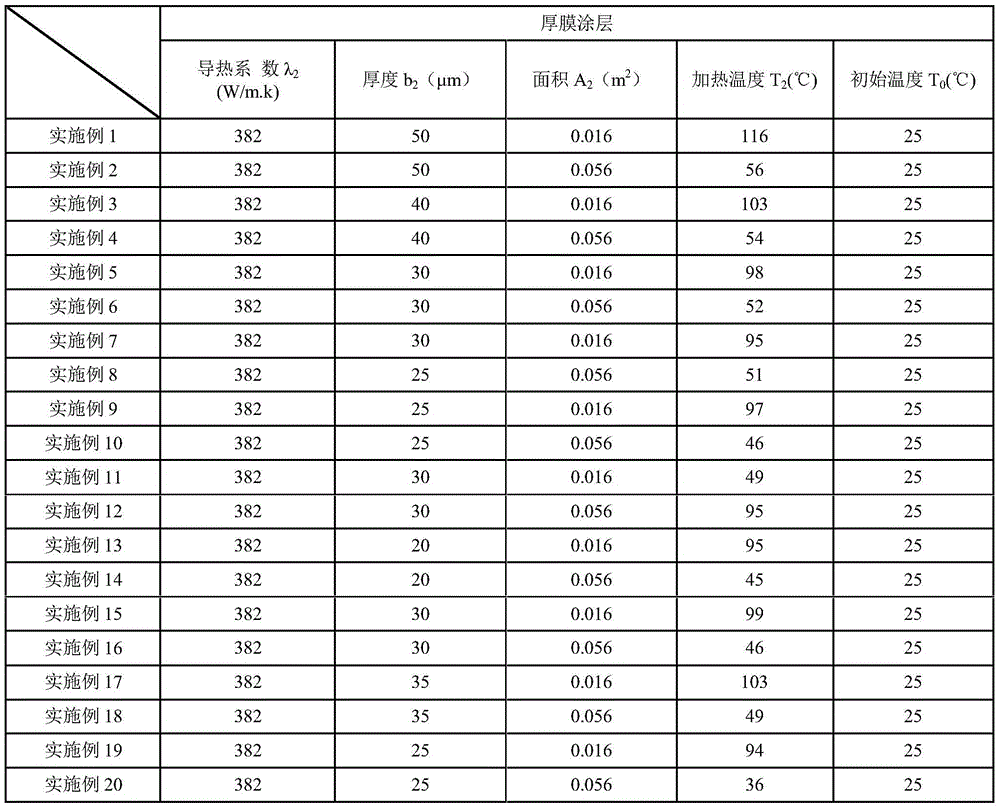

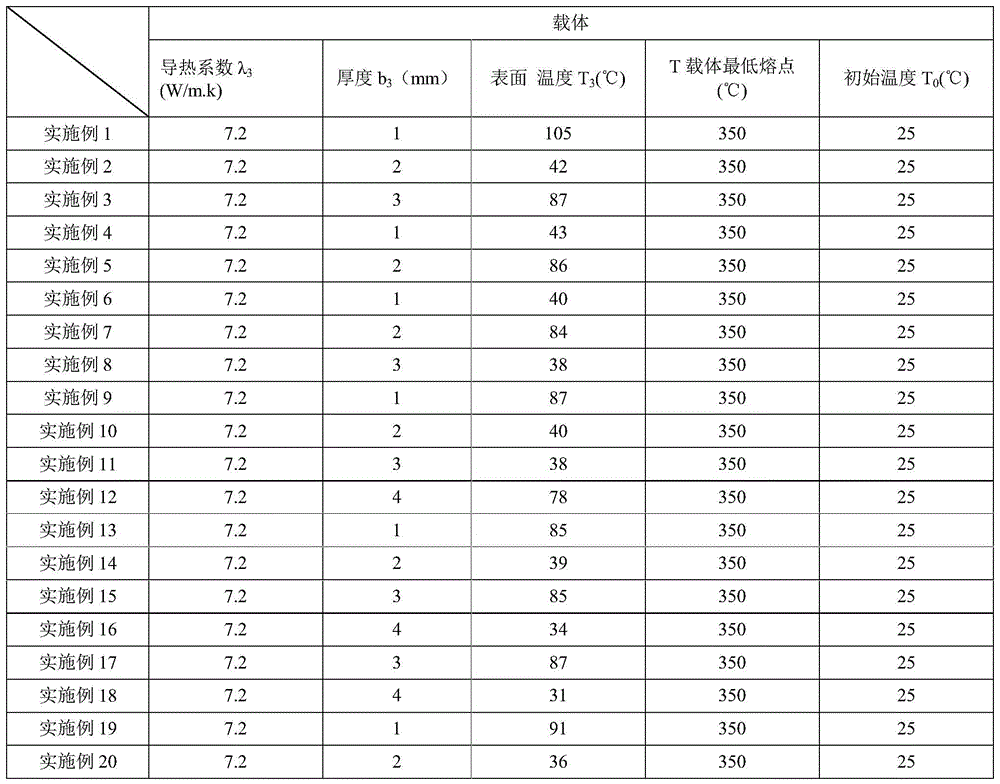

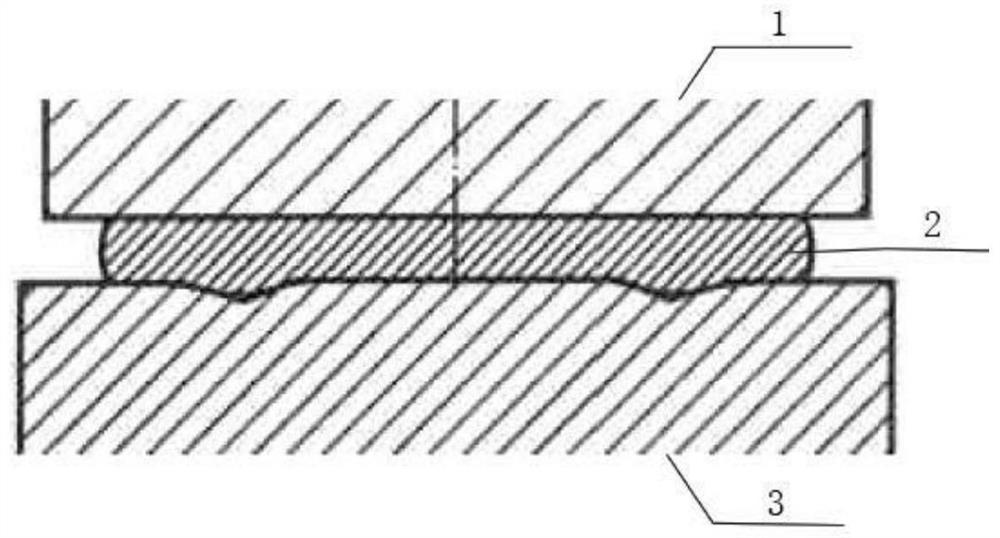

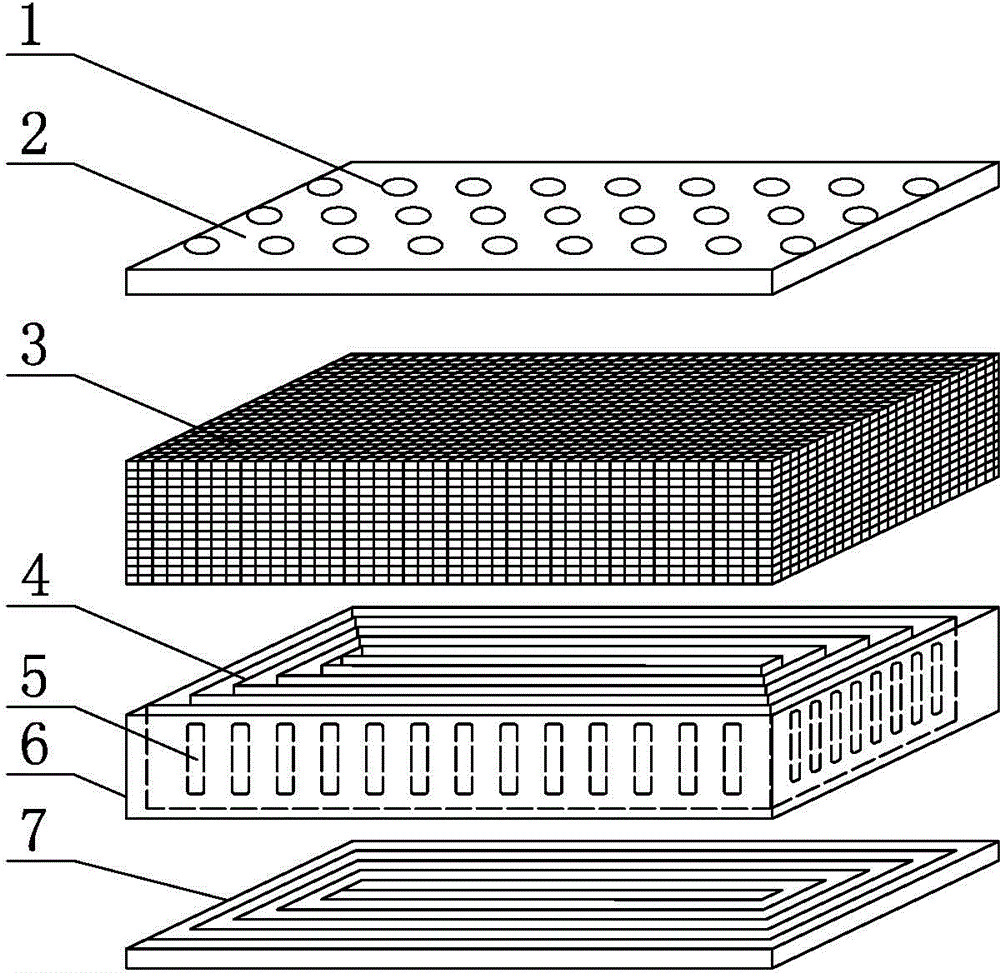

Thick film heating element with high double-sided heat conduction capability

ActiveCN106686773AEvenly heatedImprove thermal conductivityHeater elementsHeating element materialsMetallurgyHeat transfer efficiency

The invention provides a thick film heating element with high double-sided heat conduction capability. The thick film heating element is characterized by comprising a carrier, a thick film coating which coats the carrier, and a covering layer covering the thick film coating, wherein the thick film coating is a heating material; the heating mode is electric heating; and material selection of the covering layer, the thick film coating and the carrier meets the inequations as follows: Q2 is greater than or equal to Q3, Q2 is greater than or equal to Q1, Q1 is equal to a*Q3, Q2 is equal to b*Q1 and Q2 is equal to c*Q3 in a heat transfer process, wherein a is smaller than or equal to 150 and greater than or equal to 0.1, b is smaller than or equal to 2500 and greater than or equal to 1, and c is smaller than or equal to 10,000 and greater than or equal to 100. The thick film heating element has high double-sided heat conduction capability, double-sided heating is relatively uniform and the heat transfer efficiency is improved. The thick film heating element provided by the invention can be applied to a product requiring the high double-sided heat conduction capability, and meets the requirements of a multifunctional heating product in the market.

Owner:GUANGDONG FLEXWARM ADVANCED MATERIALS & TECH CO LTD

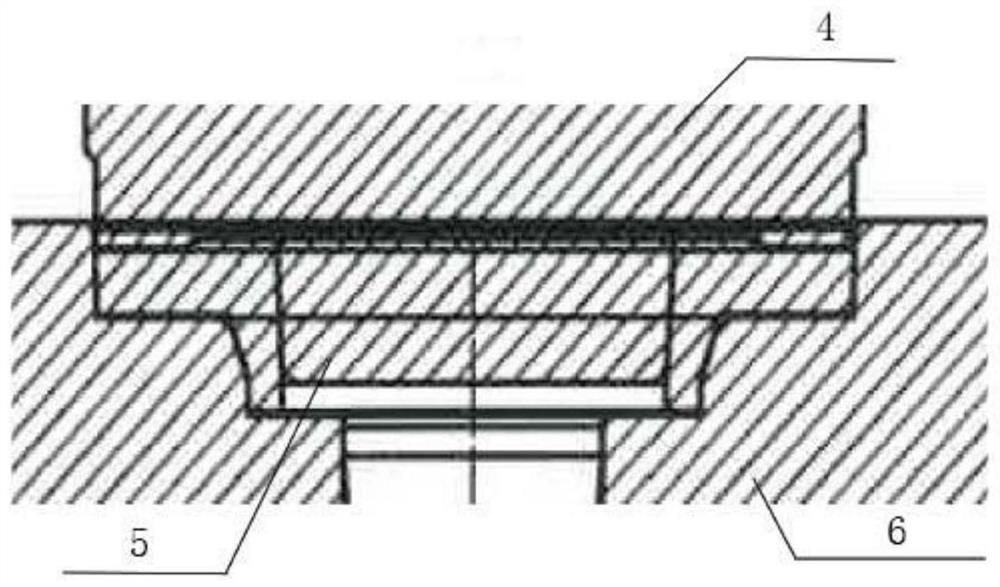

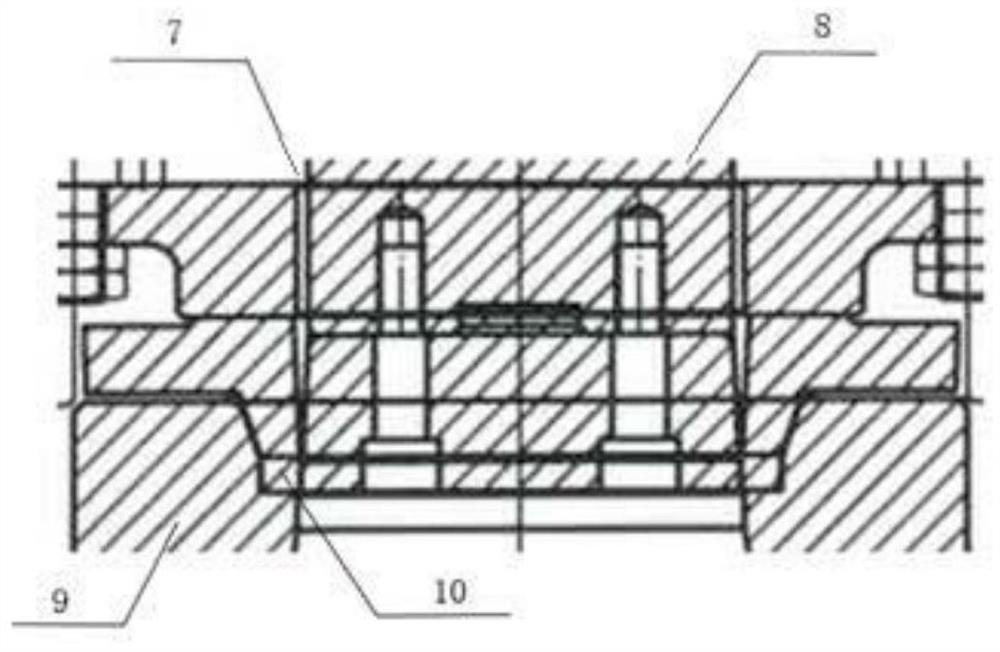

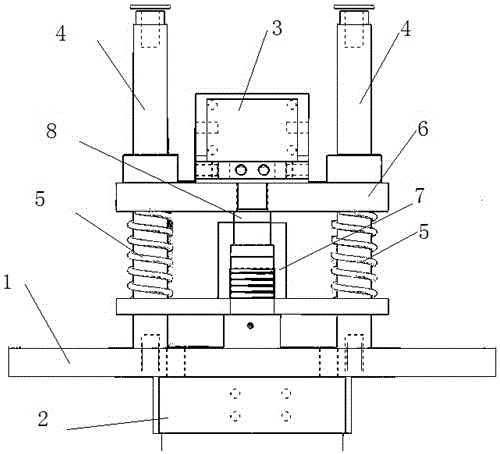

Process for forging and forming welding neck flanges for connecting pipelines

InactiveCN112475203AUniform heating rateUniform temperatureMetal-working apparatusWheelsPunchingIntermediate frequency

The invention belongs to the technical field of forging of flanges and particularly relates to a process for forging and forming welding neck flanges for connecting pipelines. The process comprises the following steps: blanking, heating, preforming, forming and punching. An intermediate frequency furnace is used for heating blanks; the blanks are firstly preformed and upset into cake shapes afterbeing heated, and then the upset blanks are inversely placed into a forming die and are closed and formed; in the preforming process, a 1000T electric screw press is used for preforming and upsettingcylindrical blanks; then a neck part of a 2500T electric screw press forming die is filled by a punch; and 315T closed single-point punching is used for cutting off the connected skin and blanking. The process has the beneficial effects that accurate discharging is achieved after allowance is added to the finished product; the sizes of the forged products are uniform and controllable; stable batchproduction is realized; the production efficiency is improved; in addition, the effects of saving the cost and reducing the time consumption are achieved; and the the economic benefit is increased.

Owner:SHANDONG IRAETA HEAVY IND

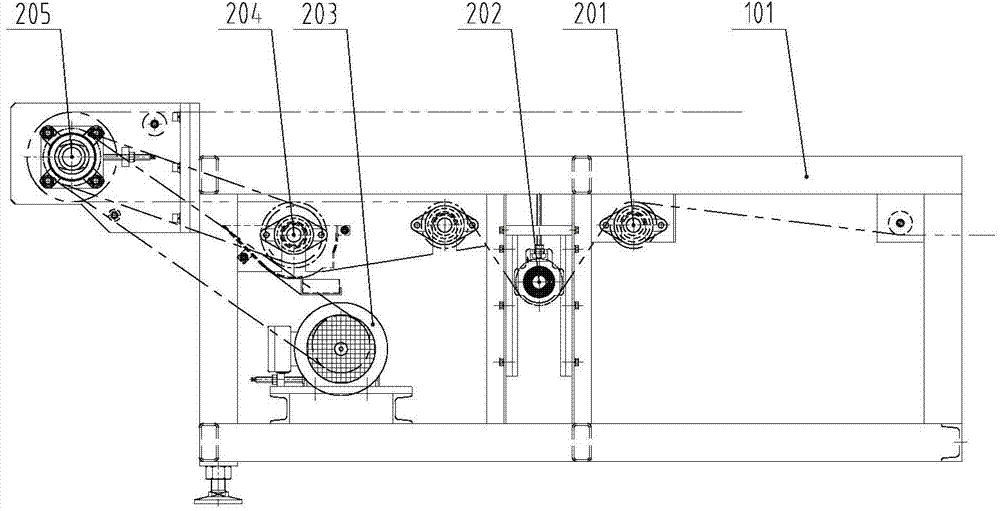

Heating electrode for reinforcement heated and upset end

ActiveCN105903868AAvoid offsetPrevent offset, etc., can effectively prevent the end of the steel bar from bendingMetal-working apparatusPower apparatusElectric spark

The invention discloses a heating electrode for a reinforcement heated and upset end. The heating electrode comprises an electrode bracket; a power device and a heating electrode are arranged on the electrode bracket; the power device pushes the heating electrode to move, or pushes the electrode bracket to drive the heating electrode to move; a slide column is arranged on the electrode bracket, and is provided with a spring; the front end of the spring is arranged at the back end of the heating electrode; the back end of the spring is fixed; and a spring located in a compression state applies the spring acting force to the heating electrode. The heating electrode is a floating form, continuously generates the thrust in the heating process, guarantees no release between the electrode and the end surface of a reinforcement due to heating softness of the reinforcement, is uniform and fast in heating, can prevent generation of electric sparks, is high in heating efficiency, only needs the time of about 2 seconds, and improves the machining efficiency.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

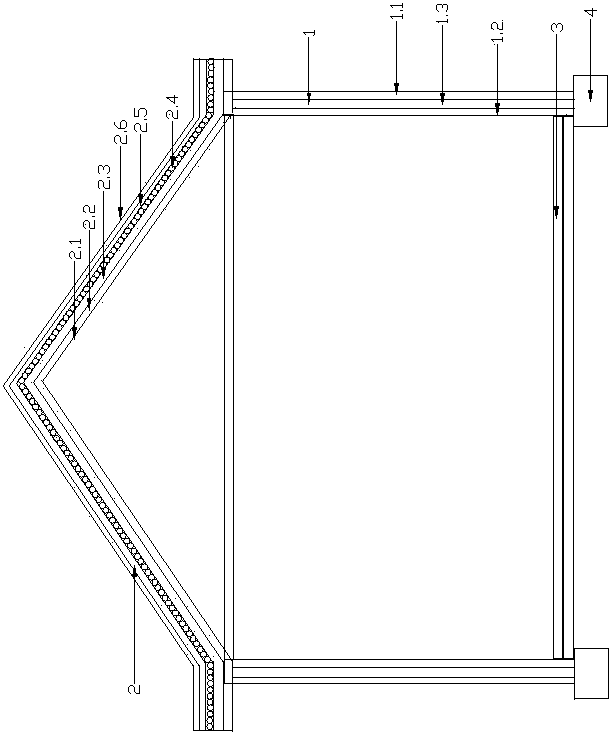

Waterproof wooden house based on assembly-type tenon-mortise connection process and manufacturing method thereof

InactiveCN109629694AUniform heating rateReduce deformation and crackingWood treatment detailsThermal wood treatmentMortise and tenonAgricultural engineering

The invention discloses a waterproof wooden house based on an assembly-type tenon-mortise connection process and a manufacturing method thereof. Each wood board used for the waterproof wooden house issubjected to ventilation pre-drying, steam drying, carbonization and other pretreatment, and then erection of wall body parts, a roof part and a foundation part is carried out step by step. Therefore, the waterproof performance of the wooden house is improved, the internal moisture of the wooden house is reduced, and the anticorrosion durability of the wooden house is ensured.

Owner:常德湘联木业有限公司

Biomass fuel particle and production process

InactiveCN109022094AHigh combustion valueExtended burn timeBiofuelsSolid fuelsCoalProcess engineering

The invention discloses a biomass fuel particle. The biomass fuel particle is prepared from the following raw materials in parts by weight: 68 to 93 parts of biomass raw materials, 52 to 68 parts of biomass charcoal powder, 42 to 56 parts of bentonite, 23 to 26 parts of dechlorinating agents, 12 to 23 parts of denitrfying agent activating agents, 16 to 23 parts of igniting agents, 13 to 19 parts of combustion improvers, 8 to 16 parts of dewatering agents, 7 to 13 parts of sodium nitrate, 34 to 46 parts of coal slime, 4 to 8 parts of white stone powder and 12 to 15 parts of kyanite. The biomassfuel has the advantages that the combustion value is high; the combustion time is long; after the combustion, no harmful gas and acid gas is discharged; meanwhile, igniting agents and combustion improvers are added; the combustion point of the fuel is greatly reduced; the ignition is easy; bentonite, kyanite and white stone powder are added; the ventilation performance is improved; the heat energy utilization rate is improved. The process requirements are low; the cost is low; the heating speed is higher; the uniformity is higher; the heating drying efficiency is higher.

Owner:滁州三丰科技有限公司

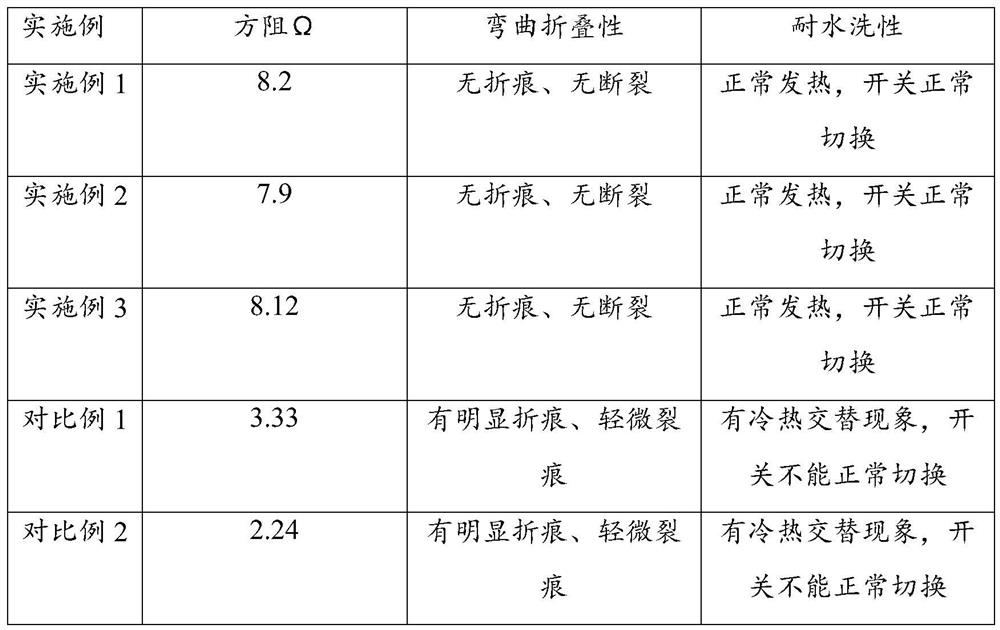

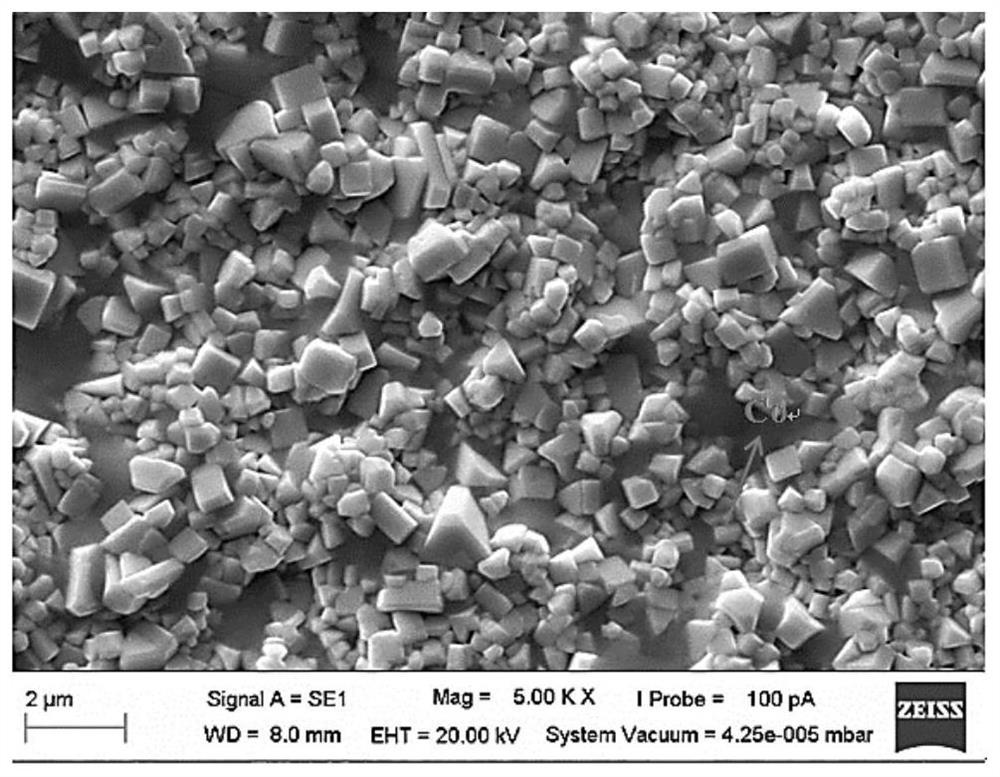

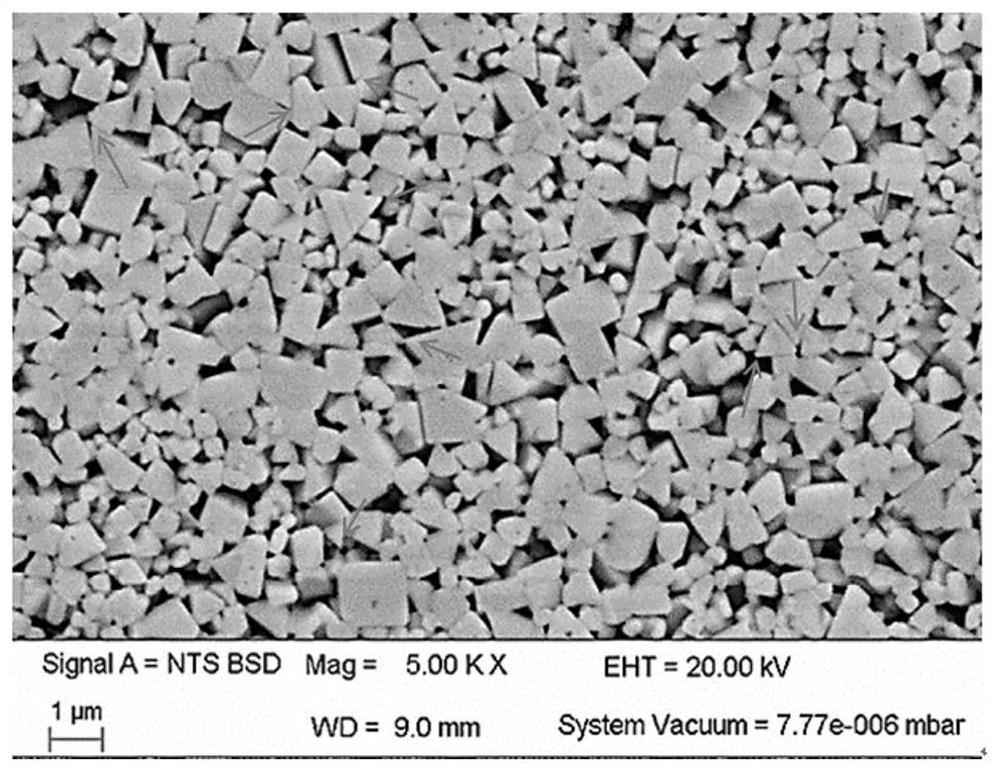

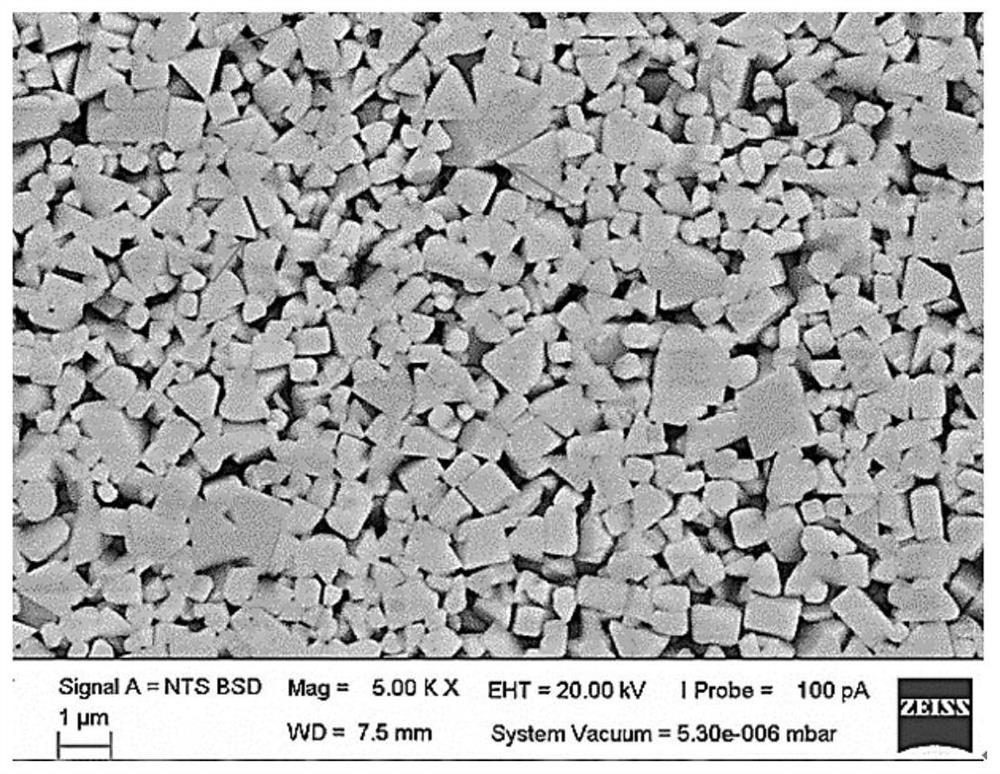

Preparation method and application of large-area flexible electric heating sheet

PendingCN113630916AExcellent electric heating performanceAvoid hard textureOhmic-resistance electrodesHeating element materialsThin membraneChemistry

The invention discloses a preparation method and application of a large-area flexible electric heating sheet. The preparation method at least comprises the following steps: (1) preparing a nano carbon composite film; (2) punching the film; (3) attaching a flexible conductive electrode; (4) laminating a heat-conducting film; and (5) surface flexible base material lamination. In the application, the flexible electric heating sheet prepared by the composite preparation method of the nano-carbon composite film and the multi-layer functional layer film has excellent electric heating performance, meanwhile, the defects of hard texture, obvious foreign body sensation, poor air permeability and the like of some existing electric heating sheets are avoided, and the flexible electric heating sheet has excellent electric heating efficiency and bending and washing resistance, and thus, has a wide development prospect.

Owner:深圳市煦阳新材料技术有限公司

Sintering method for low-stress hard alloy mold material

The invention discloses a sintering method for a low-stress hard alloy mold material. The sintering method comprises the following steps of hydrogen positive-pressure dewaxing, nitrogen hydrogen discharging, vacuum sintering, low-pressure sintering, cooling for the first time, re-burning for destressing and cooling for the second time; in the step of re-burning for destressing, firstly, the temperature is increased to 1200 DEG C and kept, and secondly, the temperature is increased to 1300-1320 DEG C and kept; and in the step of cooling for the second time, natural furnace cooling to 60 DEG C or below is carried out, and then discharging is carried out to obtain a low-stress hard alloy mold material product. The method has the advantages that equipment such as an annealing and tempering furnace, a subzero treatment furnace and a grinding machine and corresponding workloads do not need to be additionally added, and the sintering stress of the product can be effectively reduced and the fracture toughness of the product can be improved by adding the steps of re-burning for destressing and cooling for the second time in an original dewaxing-sintering integrated low-pressure furnace.

Owner:九江金鹭硬质合金有限公司

Natural gas kiln with combustion atmosphere control and method for burning Jian zhan bowl

PendingCN109631582ASolve technical problems that cannot meet the requirements of reducing atmosphereUniform temperatureFurnace typesGas emission reductionAutomatic controlNatural gas

The invention relates to a natural gas kiln with combustion atmosphere control and a method for burning a Jian zhan bowl. The natural gas kiln comprises a furnace body, a furnace door, a natural gas combustion system, a sagger, a thermocouple and a PLC automatic control system. The natural gas combustion system is electrically connected with the thermocouple and the PLC automatic control system, the sagger is arranged in the furnace body and forms a closed space, natural gas feeding ports which are arranged in a penetrating mode are formed in the furnace body and the sagger, and the natural gas feeding ports are connected with the natural gas combustion system. The natural gas combustion system is adopted, the high efficiency and environmental protection are achieved, the temperature in the kiln is uniform, the sagger forms the closed space used for accommodating the Jian zhan bowl and further used for building a strong reducing atmosphere, and the technical problem that an existing natural gas kiln can not meet the reducing atmosphere is solved. According to the method for burning the Jian zhan bowl, the reducing atmosphere is controlled by injecting natural gas into the sagger during the reduction and burning process, the automatic control is realized through the temperature control system and the combustion atmosphere, and the production scale of the Jian zhan bowl is expanded.

Owner:深圳中燃能源研究中心有限公司

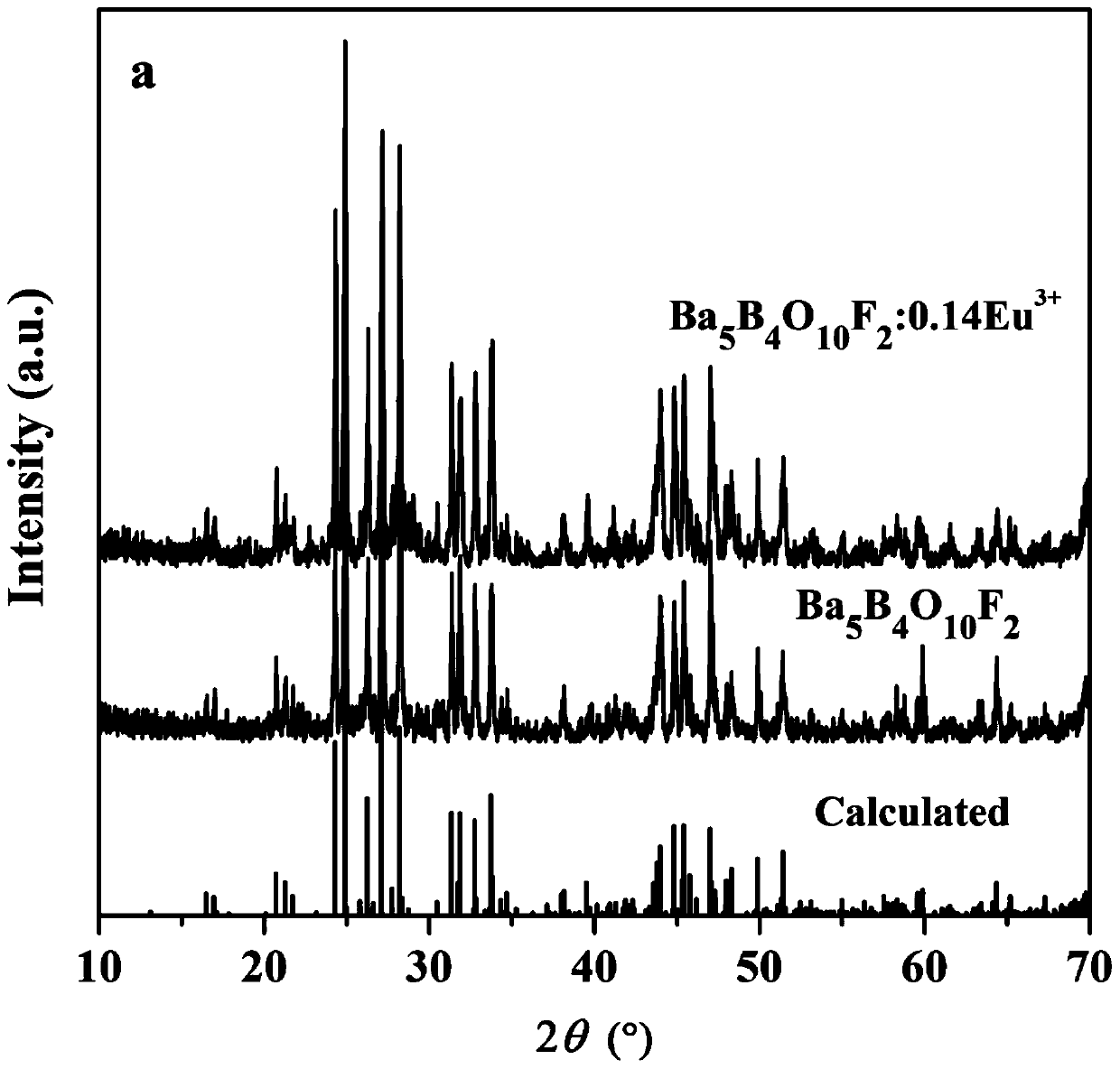

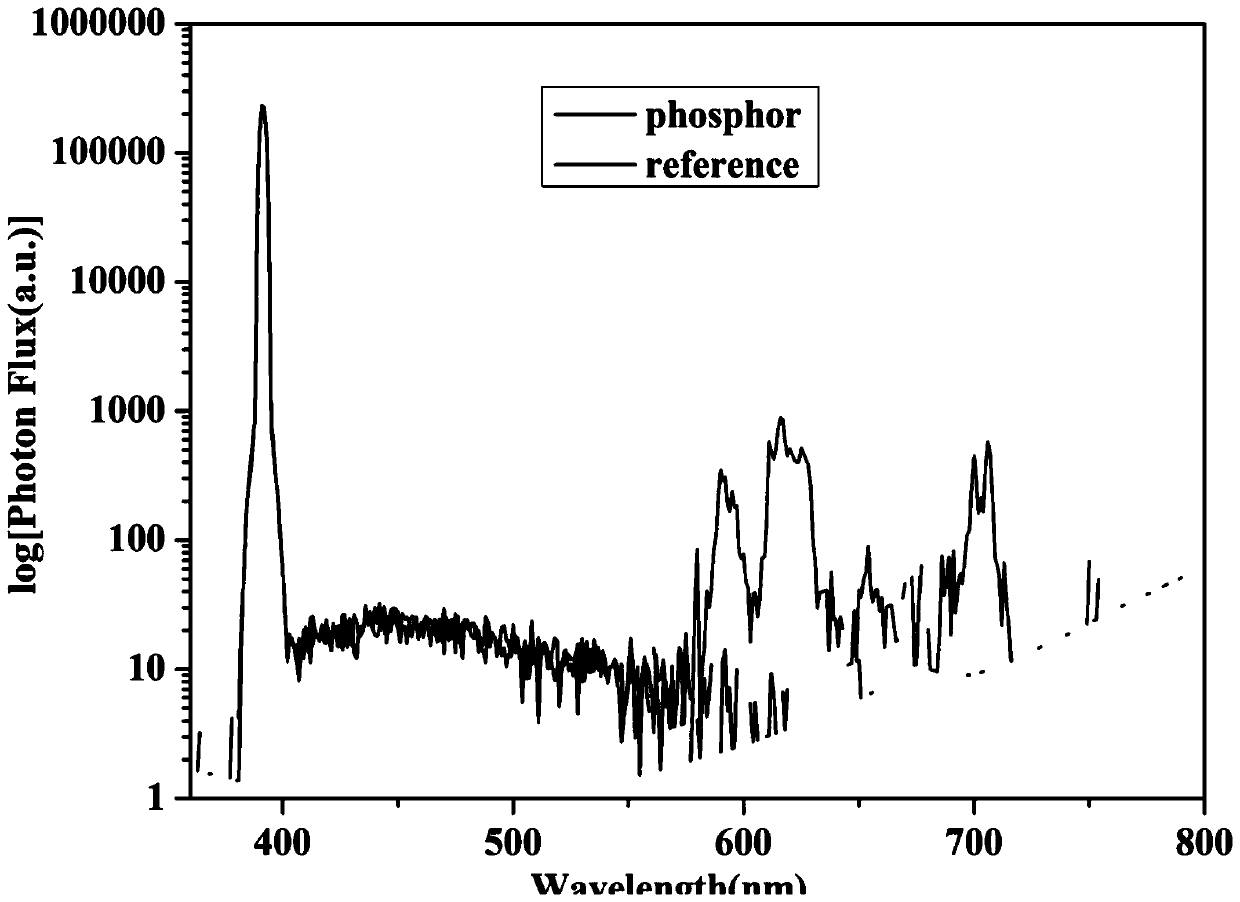

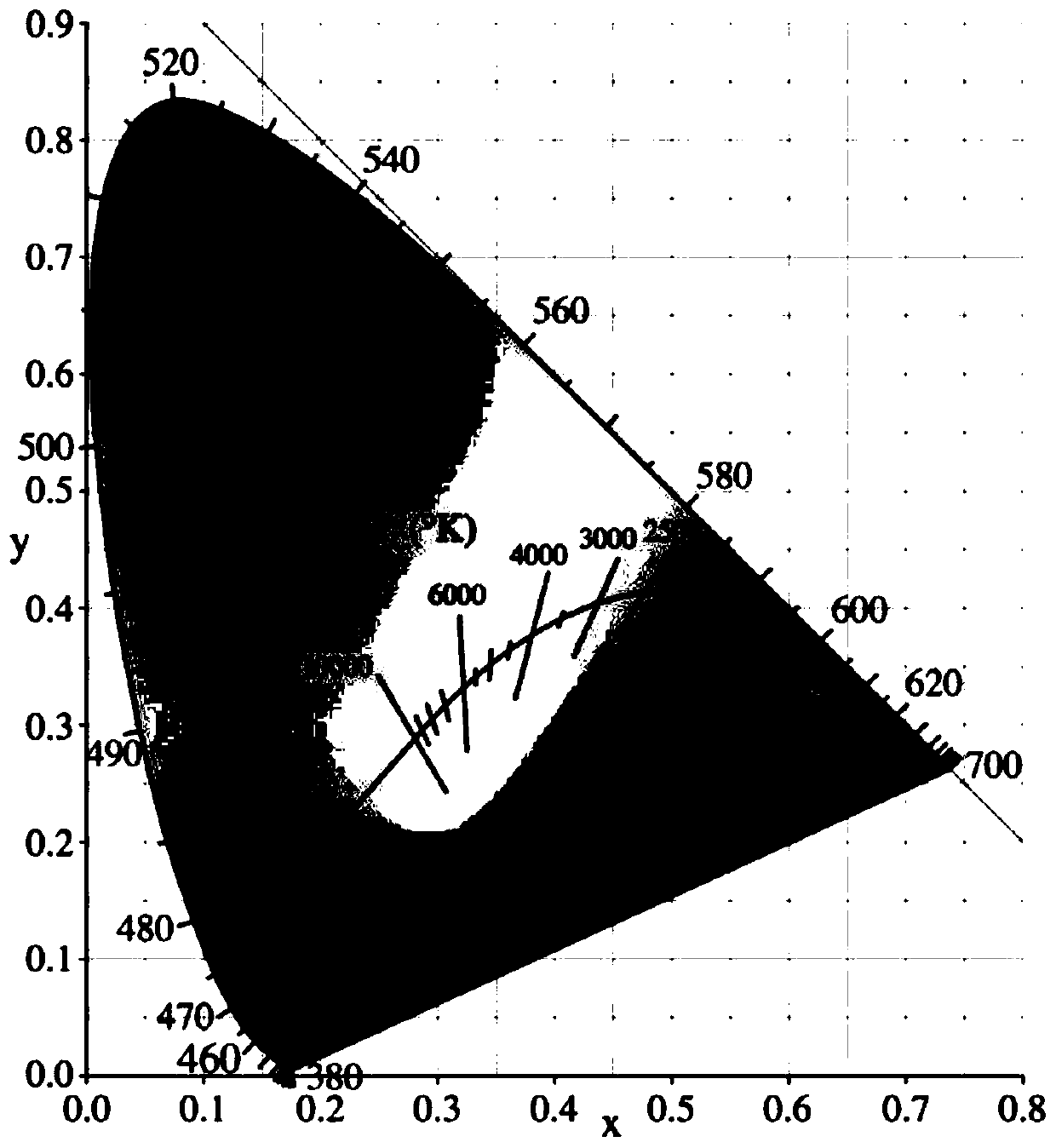

Preparation method of red fluorescent powder

The invention discloses a preparation method of red fluorescent powder, which comprises the following steps: (1) weighing one part of BaCO3, one part of BaF2, one part of Eu2O3 and four parts of B2O3,pouring the components into a container, and mixing and grinding for 0.5-1.5 hours to obtain mixed powder A; (2) heating the mixed powder A to 600-650 DEG C at a heating rate of 15-25 DEG C / min, keeping the temperature constant, calcining for 6-10 hours to decompose and thermally decompose BaCO3 to generate BaO, heating the mixed powder A to react to form a sintered block B, and grinding to obtain mixed powder B; (3) taking out the mixed powder B after the mixed powder B is cooled; heating to 770-785 DEG C at a heating rate of 15-25 DEG C / min, and calcining for 8-10 hours at the temperature of 770-785 DEG C; taking out and grinding for 6 to 7 times in the period; wherein grinding is conducted for 1-1.5 h each time; wherein the grinding time for each time of taking out is 30-60 minutes; finally, cooling with the furnace to obtain Ba5B4O10F2:xEu<3+> fluorescent powder. The present invention adopts a high temperature solid phase reaction method to prepare Ba5B4O10F2:xEu<3+> (x=0.01, 0.02...0.2) fluorescent powder with different doping concentrations.

Owner:TANGSHAN COLLEGE

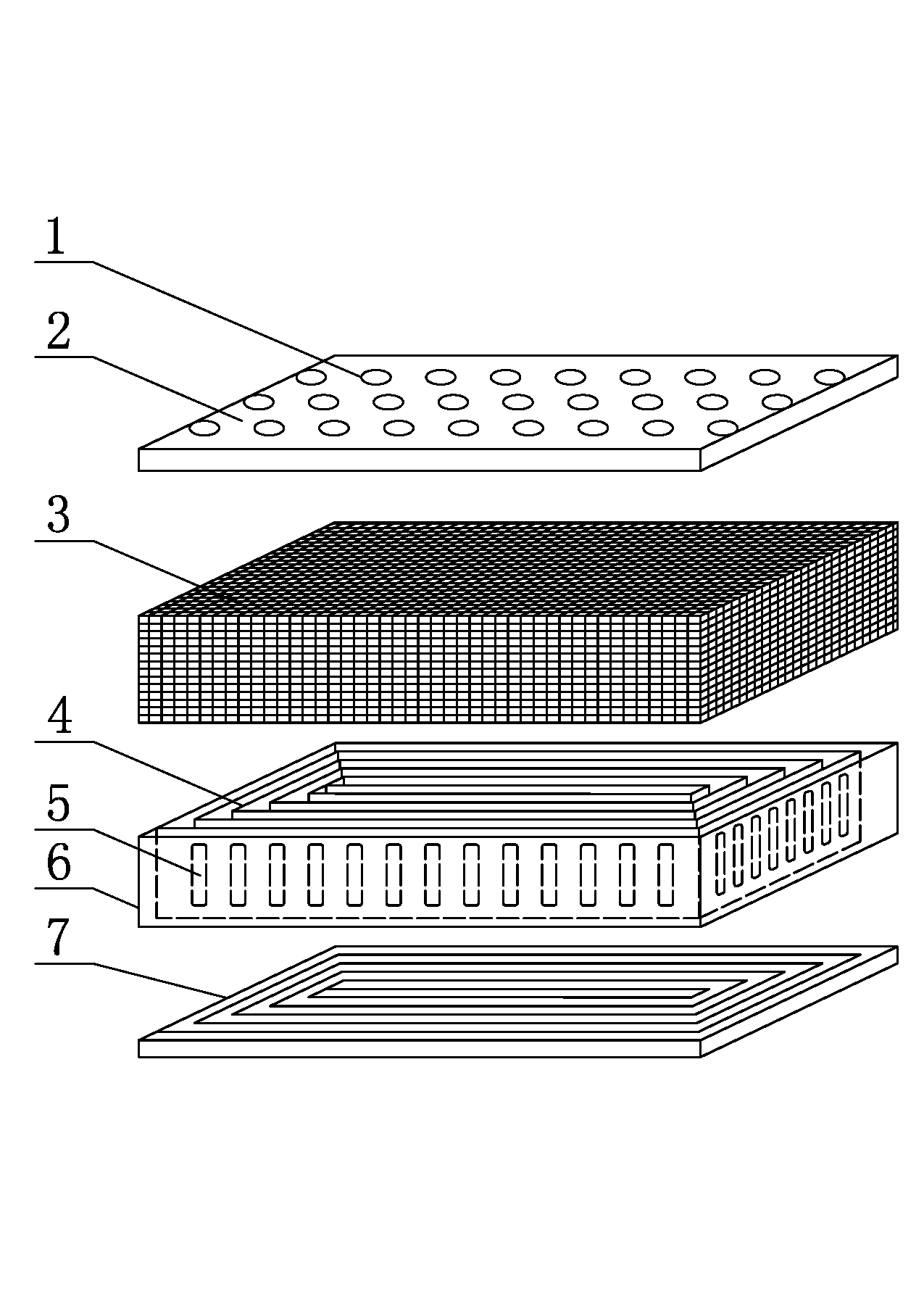

Electromagnetic water-heating magnet therapy healthcare mattress

ActiveCN103156440AEasy to useReduce energy consumptionStuffed mattressesSpring mattressesHuman bodyHigh frequency power

The invention discloses an electromagnetic water-heating magnet therapy healthcare mattress, belongs to the field of furniture for bedrooms, and particularly relates to an electromagnetic water-heating magnet therapy healthcare mattress. The electromagnetic water-heating magnet therapy healthcare mattress comprises a water cushion layer, and is characterized in that a labyrinth-shaped vertical separation layer is arranged in the water cushion layer, and a space interval in the water cushion layer is separated into labyrinth-shaped water channels which are mutually communicated by the vertical separation layer; the vertical separation layer is made from a double-layer heat-resistant and waterproof material, and more than three induction heating metal plates are arranged in the middle interlayer of the vertical separation layer; and a spiral high-frequency induction heating coil is arranged below the water cushion layer, and connected with a high-frequency power supply. The electromagnetic water-heating magnet therapy healthcare mattress is capable of uniformly heating, soft, comfortable and not easy to sway, so that the softness characteristic of the water cushion layer can be adequately exerted, and sleeping posture can be effectively improved by virtue of a memory sponge cushion layer, thus acting a good bearing effect on each physiological curved part of human body, and contributing to keeping healthy body contour and bone support; and magnetic sheets can be used for applying a positive magnetic field on the acupuncture points of human body, thus acting a good healthcare effect.

Owner:SHENZHEN ZHONGSHEN AIDE BEDDING TECH CO LTD

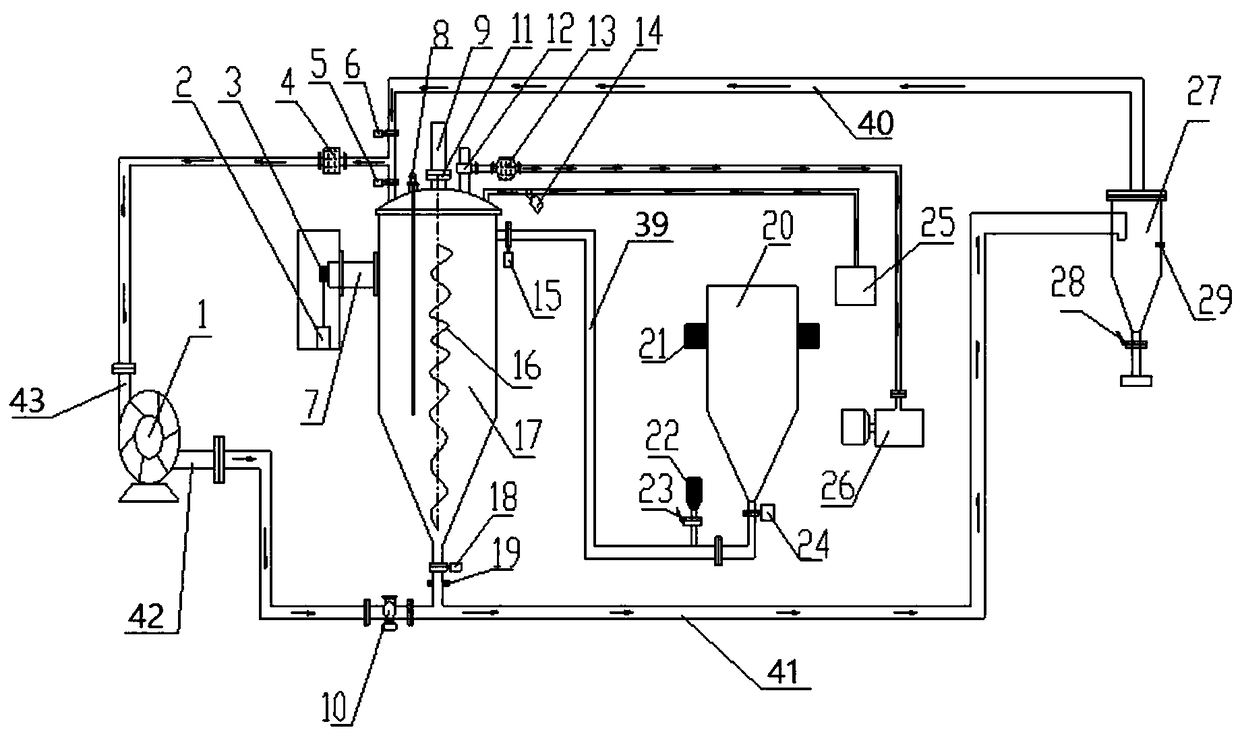

Nitrogen protection microwave vacuum drying device and drying method for optical plastic raw materials

PendingCN109489348AProtective material propertiesFast heatingDrying solid materials with heatDrying solid materials without heatMicrowaveClosed loop

The invention discloses a nitrogen protection microwave vacuum drying device and a drying method for optical plastic raw materials; the drying device is internally provided with a drying tank, a storage bin, a heater, a conveying fan, a terminal hopper and a plurality of groups of valve devices; an air inlet of the conveying fan, the drying tank and the terminal hopper are connected through an airduct; a feeding pipeline is connected between the storage bin and the drying tank; the drying tank is also connected with the terminal hopper through a discharging pipeline; the air outlet of the conveying fan is connected with the discharging pipeline through a pipeline serially connected with a three-way pneumatic ball valve; the heater is installed on the drying tank; a spiral stirrer and a temperature sensor are also provided in the drying tank; the drying tank is also respectively connected with a vacuum pump and a nitrogen membrane group; and the discharging pipeline is provided with afourth pneumatic butterfly valve and a counter-type photoelectric sensor. The nitrogen protection microwave vacuum drying device and the drying method for the optical plastic raw materials provided bythe invention can effectively prevent the optical plastics from being oxidized during the heating process, the heating speed is fast and uniform, and a closed-loop conveying system is adopted to prevent the dried raw materials from occuring the phenomenon of moisture reabsorption.

Owner:TIANJIN LAIWO VACUUM DRYING EQUIP MFG CO LTD

A method of detoxifying citrus by using microwave

ActiveCN110235661BReach lethal temperatureAchieve double sterilization effectHorticulture methodsPlant protectionCitrus volkamerianaBiology

The invention discloses a method for detoxification of citrus by utilizing microwaves, and belongs to the technical field of microwave application. The method is characterized in that during microwave pretreatment, the microwave irradiation frequency is 1.0 GHz-3.0 GHz, the power is 100-900 W, the microwave irradiation time is 5-20 seconds, then pausing is carried out for 10-30 seconds, repetitive operation is carried out 3-10 times, the temperature of each part of the citrus is increased to 40-45 DEG C, and the constant temperature is maintained for 30-60 seconds; then it is adjusted that the microwave irradiation frequency is 350 MHz-950 MHz, the power is 1,000-3,000 W, the microwave irradiation time is 3-10 seconds, then pausing is carried out for 20-60 seconds, repetitive operation is carried out 5-20 times, the temperature of each part of the citrus is increased to 50-55 DEG C, the constant temperature is maintained for 1-5 minutes, and citrus detoxification is carried out by utilizing the microwaves. The method for detoxification of the citrus by utilizing the microwaves can make each part of the citrus reach the fatal temperature of candidatus liberibacter more quickly and evenly, and a tree body is not affected; under the non-thermal effect of a microwave electromagnetic field, nucleic acid, protein and other molecules in the candidatus liberibacter are easy to denature and inactivate to achieve double sterilization effects; the detoxificated citrus through the microwaves are detected by adopting GB / T 28062-2011 <Real-Time Fluorescence PCR Detection Method of Candidatus Liberibacter>, and the negative conversion ratio of the candidatus liberibacter is greater than or equal to 82%. The method is an efficient, quick and environment-friendly citrus detoxification method.

Owner:GUANGXI ACAD OF SCI +3

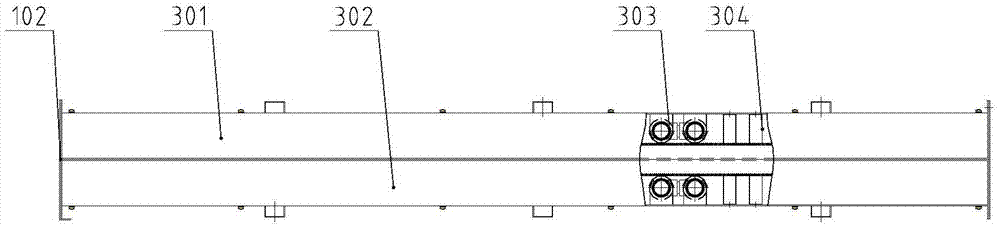

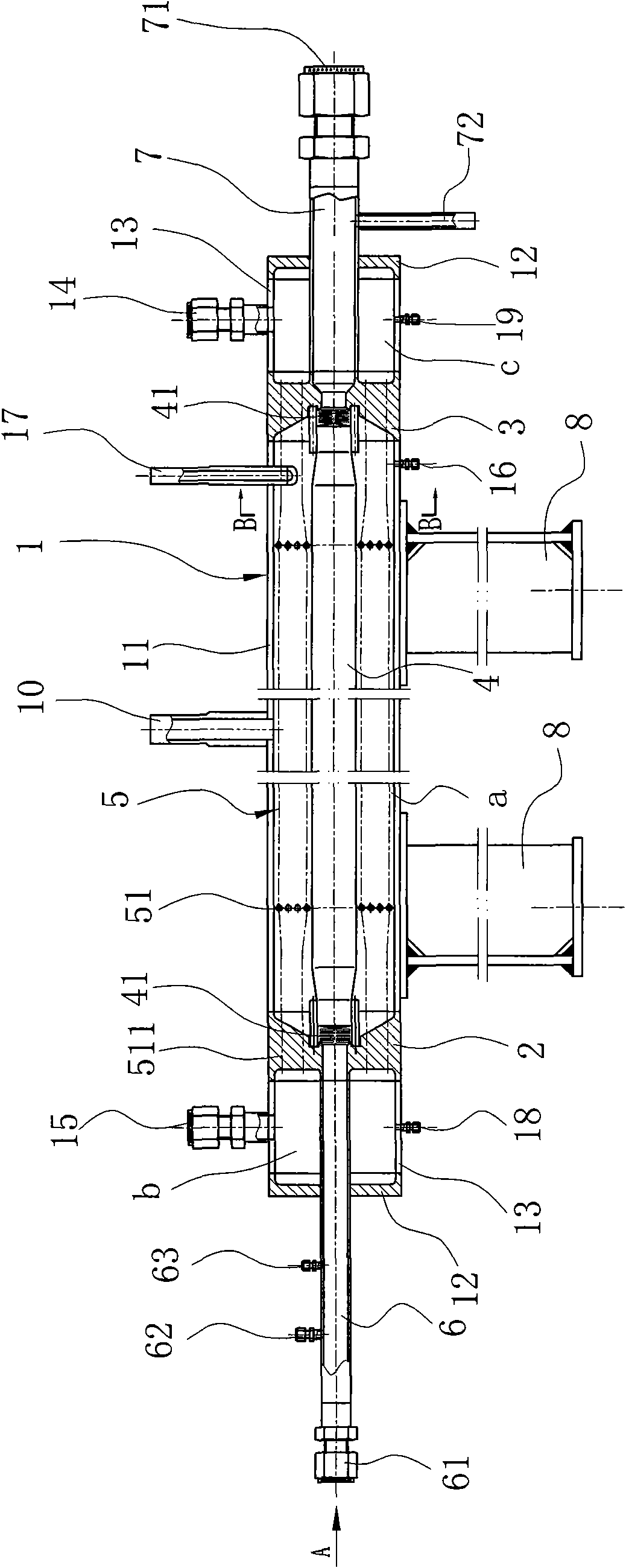

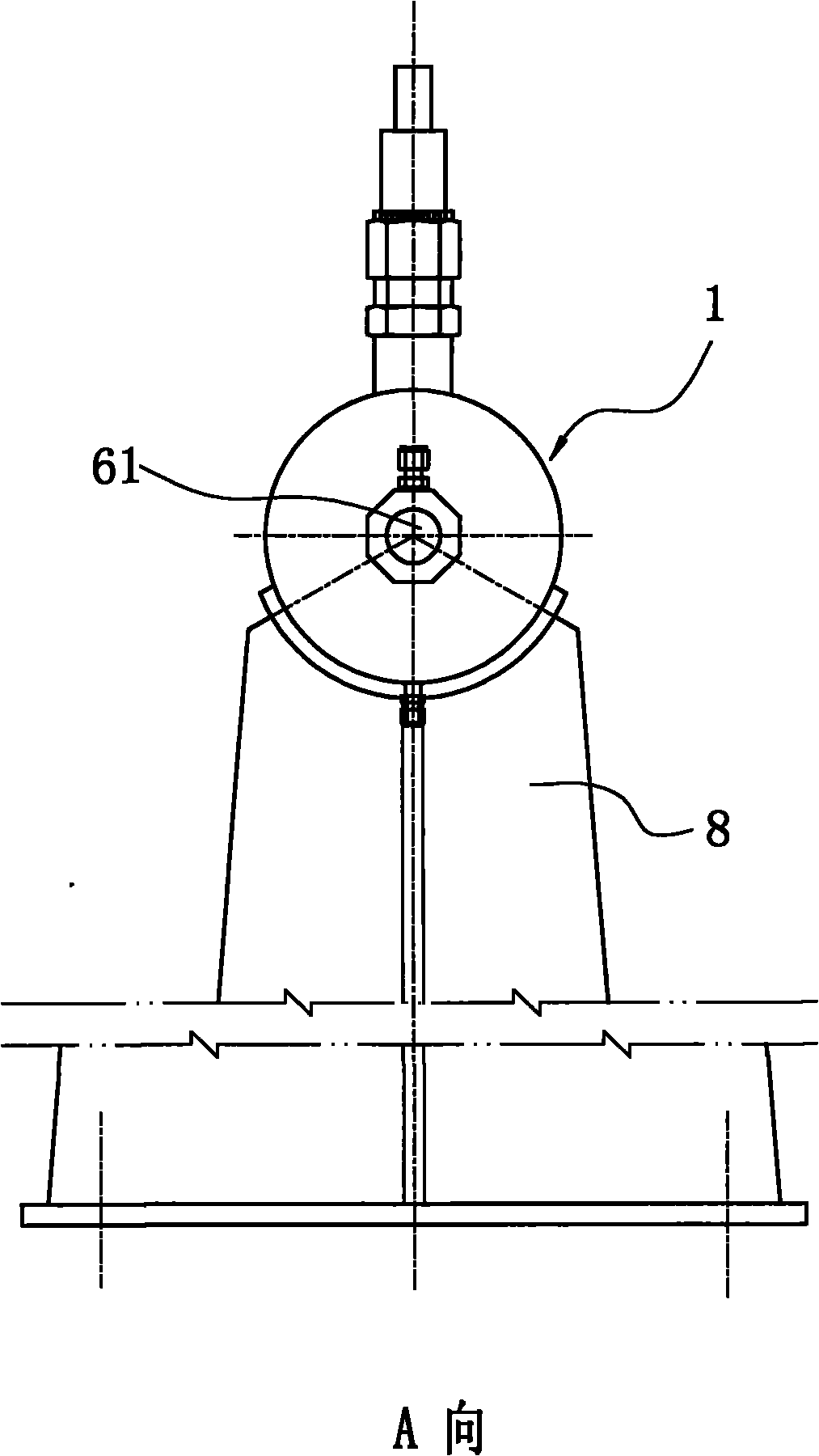

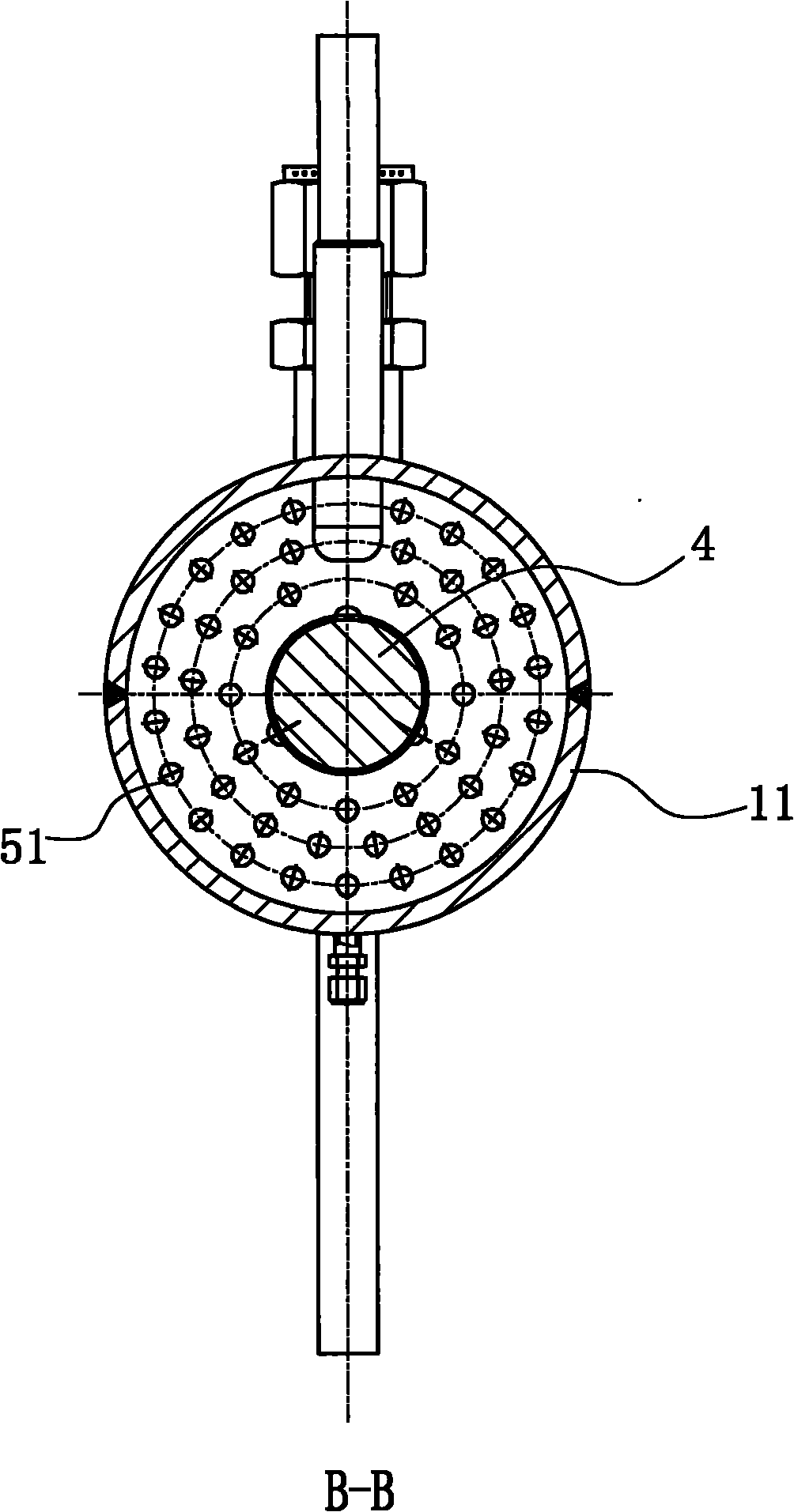

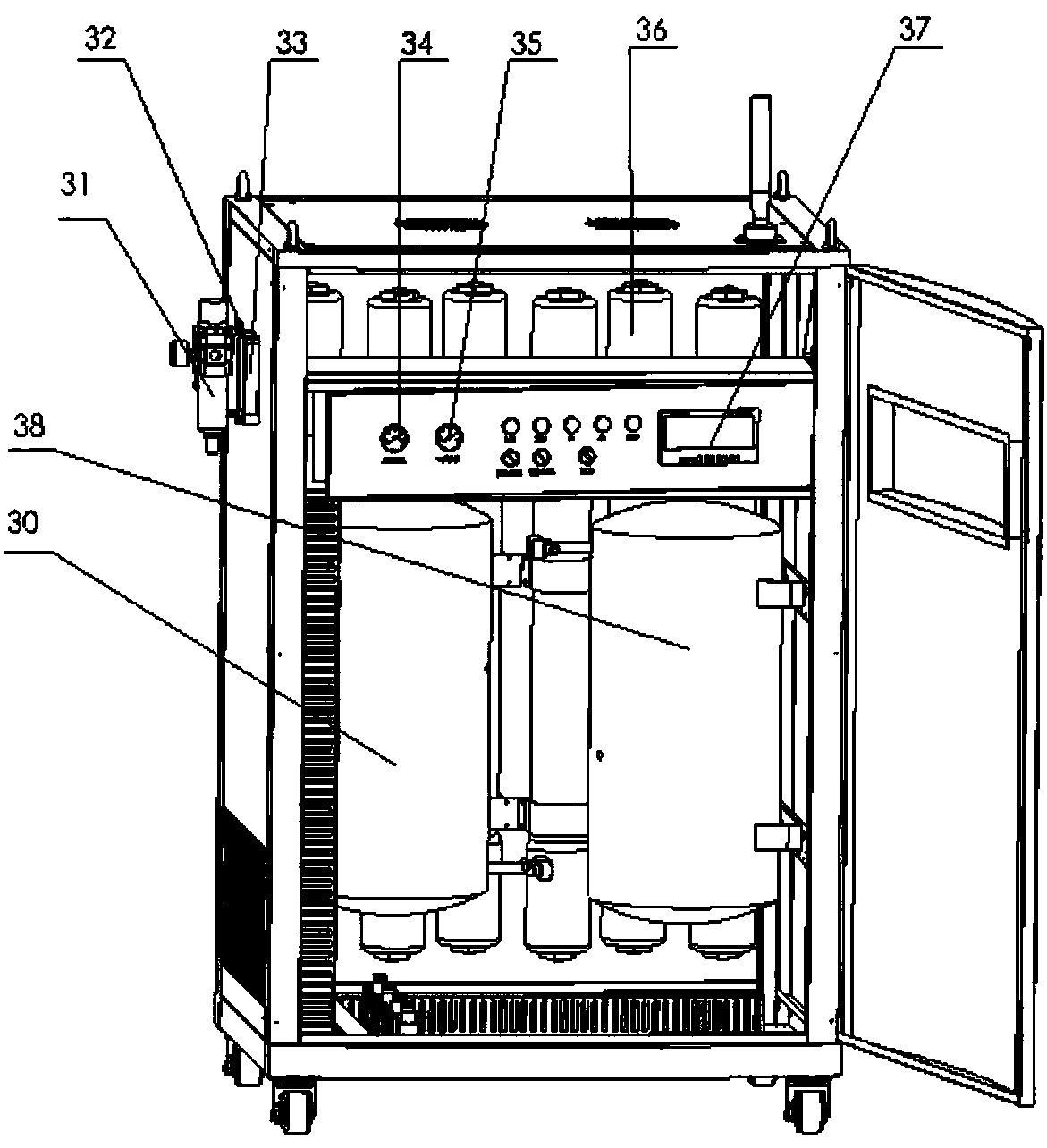

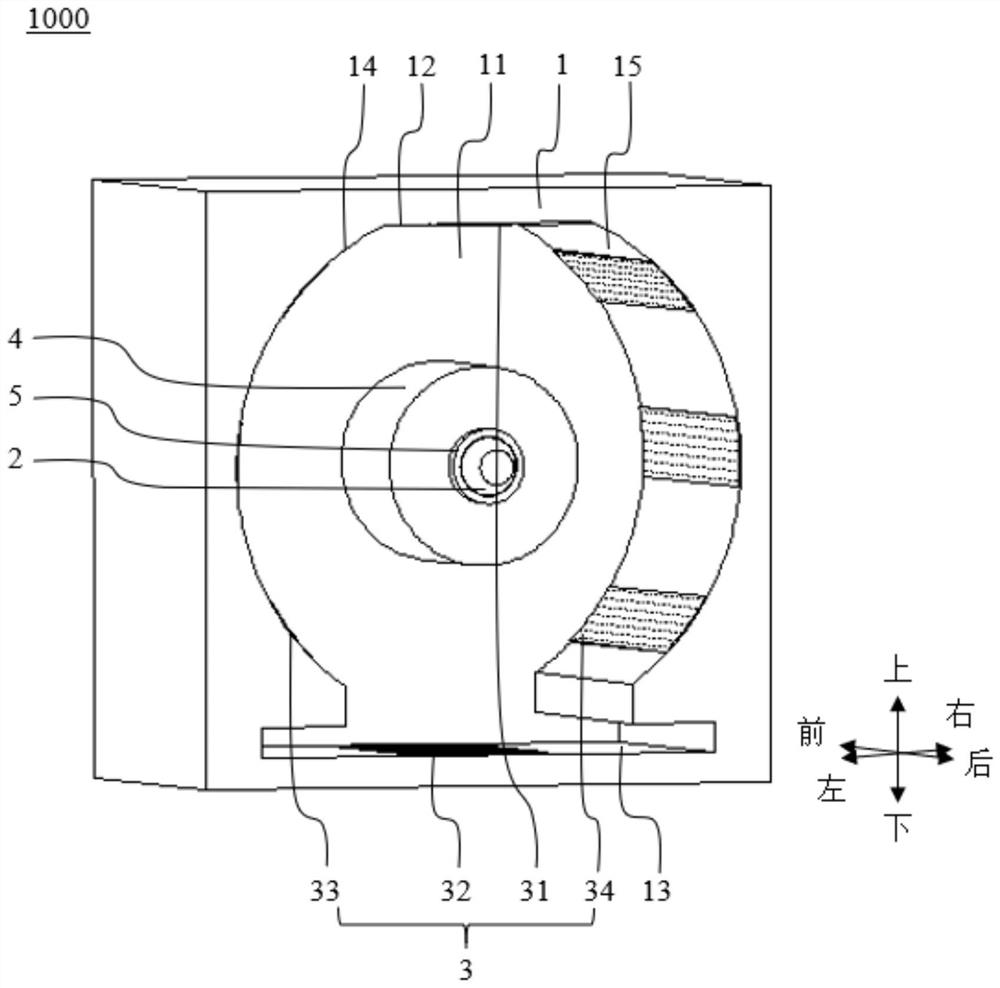

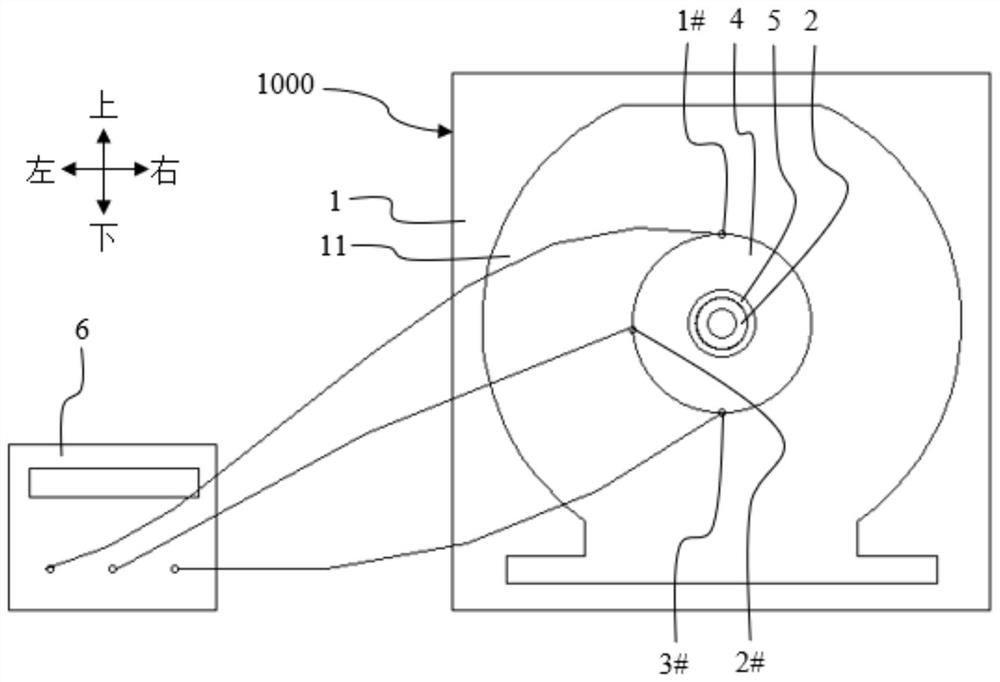

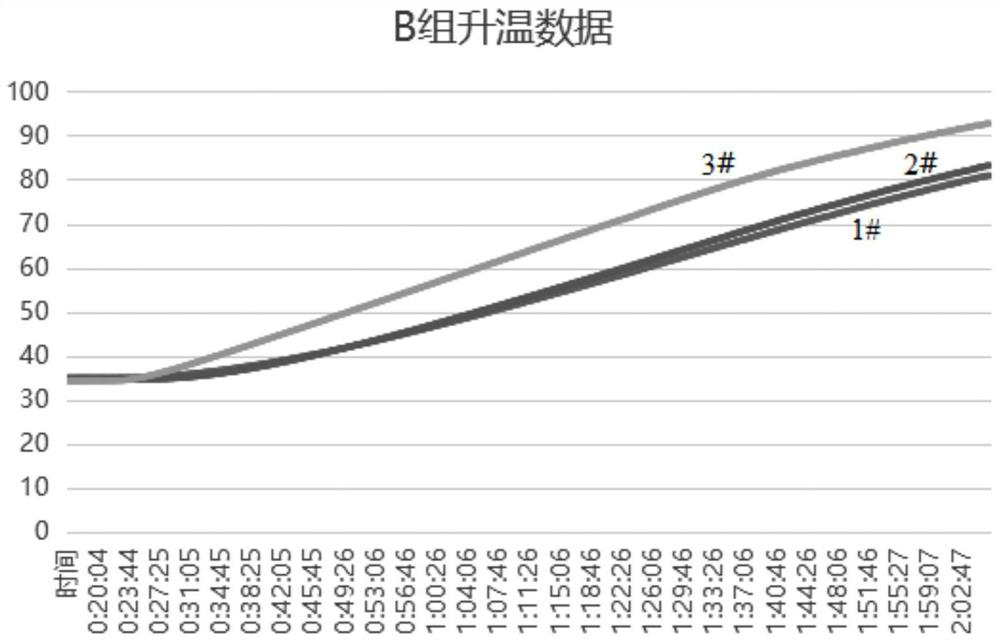

Drying oven device for lithium battery pole roll

PendingCN113967579AUniform heating rateHeating evenlyPretreated surfacesCoatingsEngineeringLaboratory oven

The invention discloses a drying oven device for a lithium battery pole roll. The drying oven device for the lithium battery pole roll comprises a drying oven cavity body, a shaft rod, heating pipes and flow guide plates; a drying oven cavity is defined by the drying oven cavity body; the shaft rod is arranged in the drying oven cavity in an extending mode in the front-back direction; the heating pipes comprise a first heating pipe and second heating pipes; the first heating pipe is arranged in the shaft rod in an extending mode in the front-back direction; the plurality of second heating pipes are arranged in the drying oven cavity body so as to uniformly heat the lithium battery pole roll; the flow guide plates comprise a top flow guide plate, a bottom flow guide plate, a left side flow guide plate and a right side flow guide plate which are correspondingly arranged on the top wall, the bottom wall, the left side wall and the right side wall of the drying oven cavity respectively; and nitrogen is guided into the oven cavity from the left side flow guide plate and the right side flow guide plate and guided out from the top flow guide plate and the bottom flow guide plate. According to the drying oven device for the lithium battery pole roll, and the temperature uniformity of the lithium battery pole roll is good when the lithium battery pole roll is baked in the drying oven device.

Owner:昆山聚创新能源科技有限公司

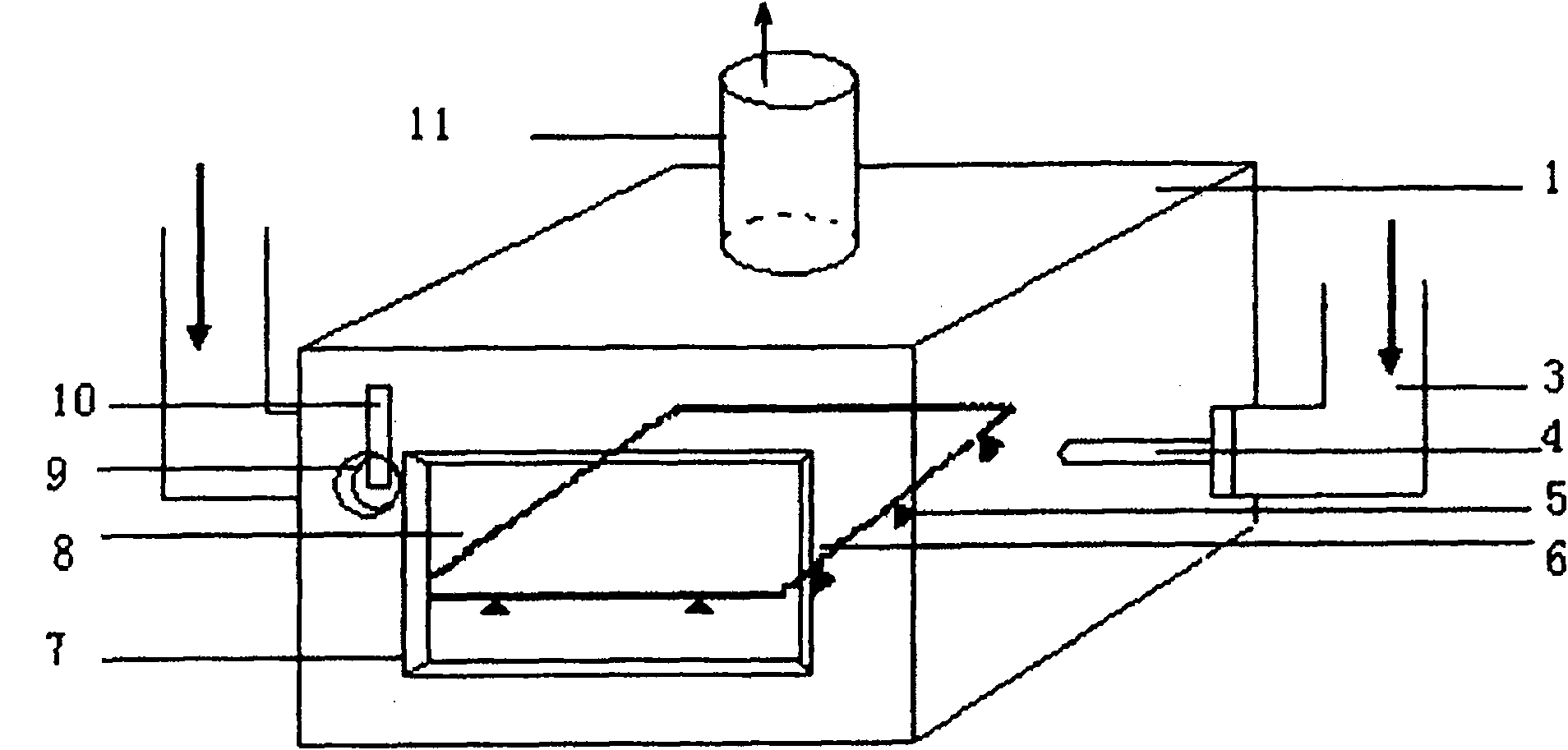

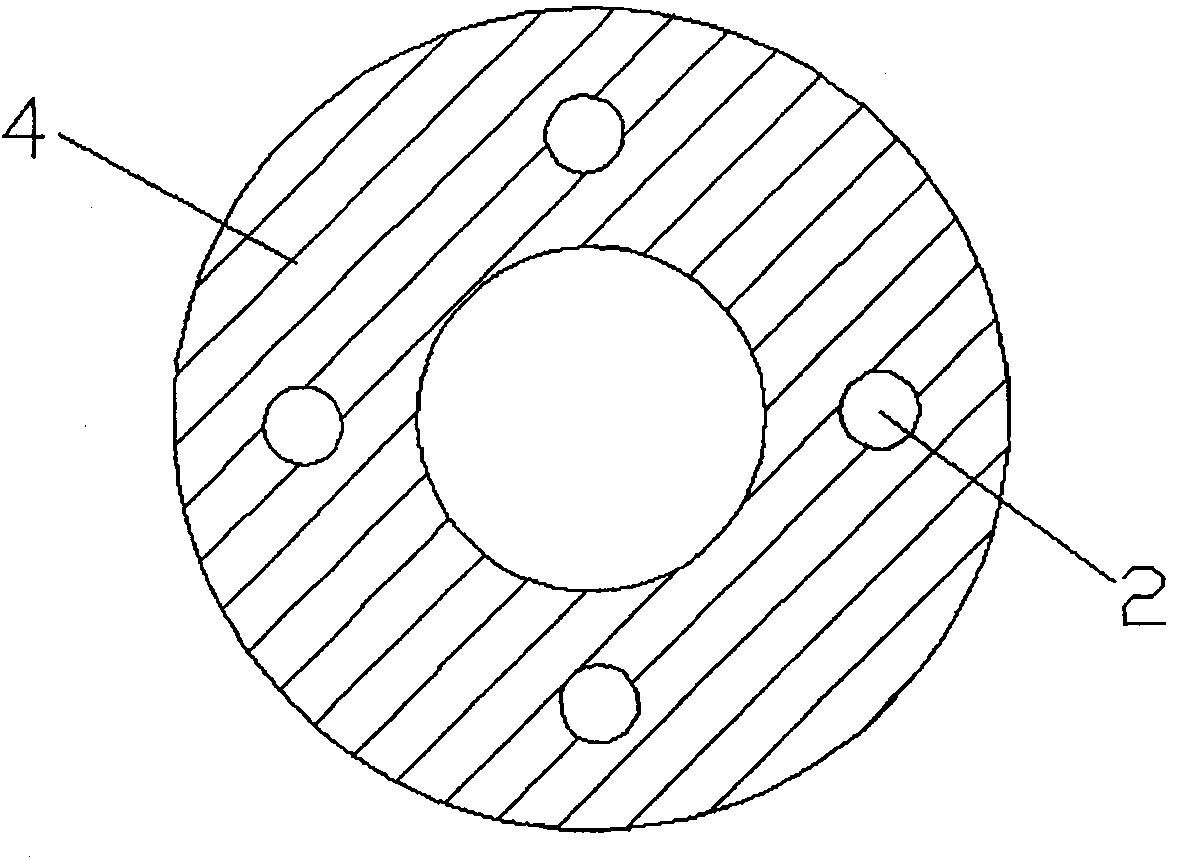

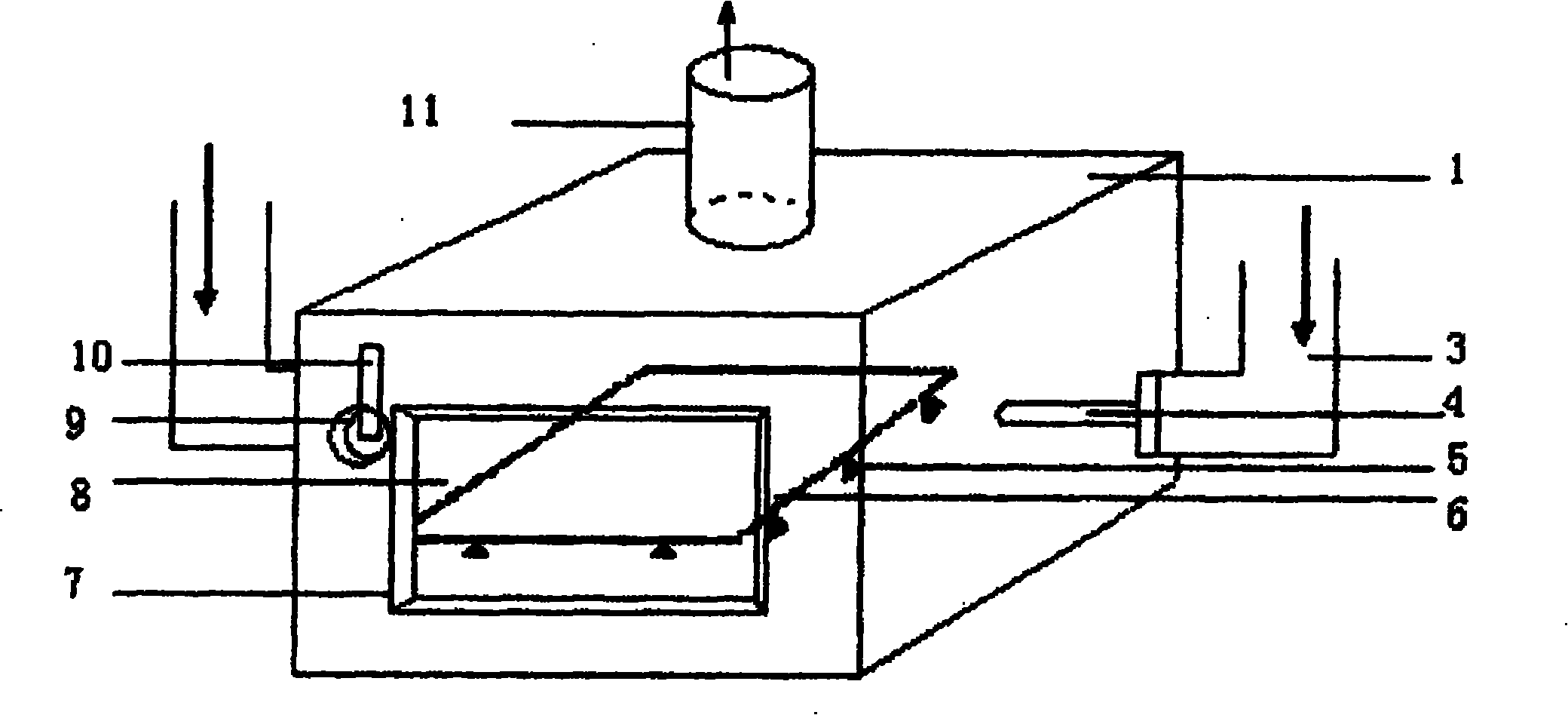

Method for nonoxidizing heating thin steel plate and special heating furnace

InactiveCN101333589BHeating evenlySimple structureFurnace typesHeat treatment furnacesSheet steelHearth

Disclosed is a non-oxidation heating method used for a thin steel plate as well as a special heating furnace, and the heating method is a method directly blowing high temperature inert gases to the thin steel plate for heating the thin steel plate. The special heating furnace comprises a furnace wall (1), a hearth (8), a furnace door (7), a belly pipe (4) for blowing the high temperature inert gases into the hearth (8), a pad iron (5) for placing the thin steel plate (6), and a flue (11); the flue (11) is disposed on the furnace wall (1) at the top part, and the flue (11) is communicated withthe hearth (8); and the pad iron (5) is arranged in the hearth (8). The method which directly blows the high temperature inert gases to the thin steel plate for heating the thin steel plate can ensure the uniform heating to the thin steel plate under the condition of non oxidation.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

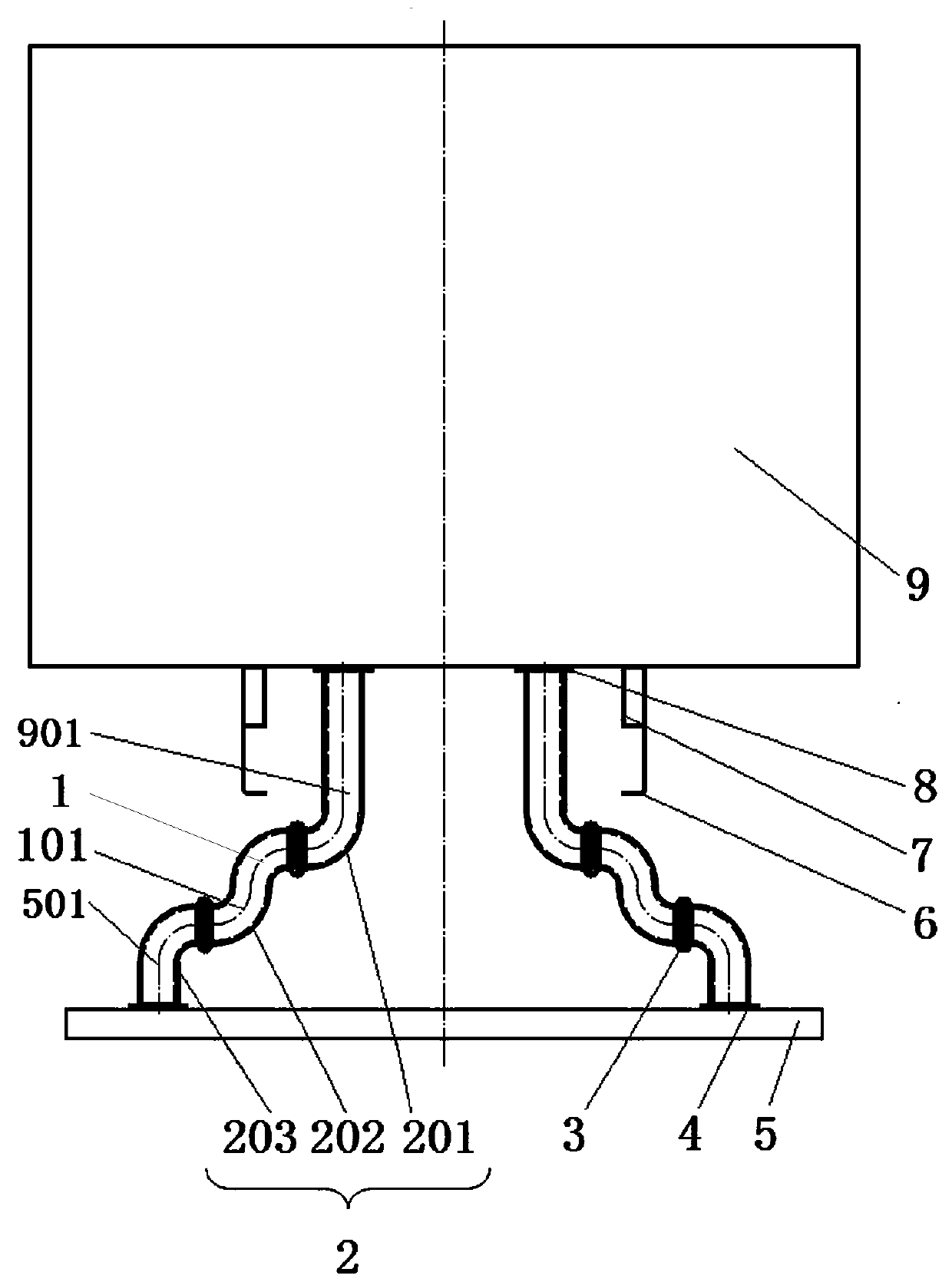

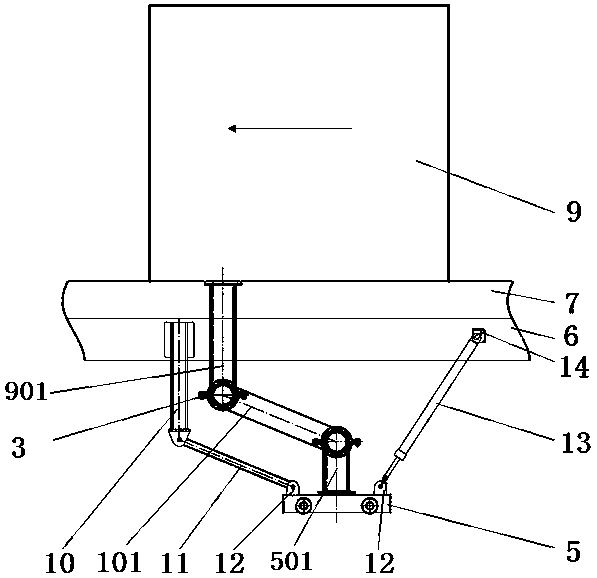

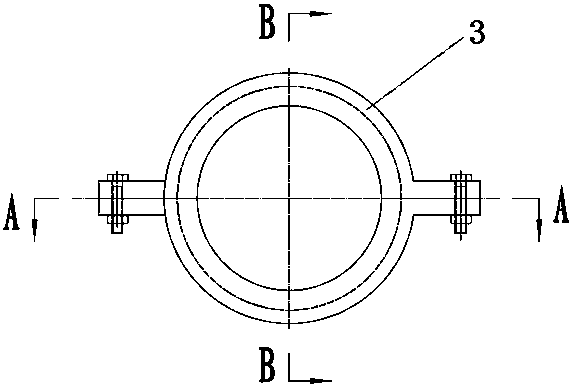

Snow sucking device connection structure of snow melting vehicle

The invention relates to a snow sucking device connection structure of a snow melting vehicle. The snow sucking device connection structure of the snow melting vehicle is arranged between a vehicle body of the snow melting vehicle and a snow sucking device below the vehicle body; the vehicle body is provided with an accumulated snow collection box; the snow sucking device connection structure of the snow melting vehicle is a negative pressure pipeline connected between the accumulated snow collection box and the snow sucking device and is a rigid pipeline; and the rigid pipeline comprises twoor more connection pipelines connected between the accumulated snow collection box and the snow sucking device in a connecting rod form, or comprises a single pipeline hinged between the accumulated snow collection box and the snow sucking device, wherein every two adjacent connection pipelines are mutually hinged. The snow sucking device connection structure is connected between the accumulated snow collection box and the snow sucking device in the connecting rod form, thus when the snow sucking device ascends or descends, the rigid pipeline can make corresponding movement to achieve the sameeffect as a flexible pipeline, but the rigid pipeline is not sucked to be flat due to the excessive pressure of the negative pressure pipeline.

Owner:HENAN SENYUAN HEAVY IND

A triple-helix household soybean milk machine

ActiveCN106943001BImprove finenessImprove uniformityVessels with intergral heatingTriple helixEngineering

The invention discloses a triple-helix household soybean milk machine which comprises a soybean milk machine body. The soybean milk machine comprises a machine head and a soybean milk grinding cavity body, wherein an electronic control panel is arranged right above the machine head, a motor shaft body is arranged under the machine head, smashing motors are arranged on two lateral walls and the bottom of the motor shaft body, a spiral smashing cutter blade is in threaded connection to the smashing motor, a casing of the soybean milk grinding cavity body is divided into two layers and filled with a water medium, a heating disk body is welded under the soybean milk grinding cavity body, an electric heater is arranged in the heating disk body, the electric heater is electrically connected with a heating disk driving circuit, a soybean milk outlet is formed in the upper left portion of the soybean milk grinding cavity body, and a static grinding assembly is arranged at the bottom of the soybean milk grinding cavity. The triple-helix household soybean milk machine disclosed by the invention has a simple structure, improves smashing efficiency by utilizing the triple-helix smashing cutter blade, improves a fine and smooth degree of soybean milk, has quick and even heating speed, is convenient to control and operate, has convenience in filtering and saves cost.

Owner:YANCHENG CHITTAGONG SMART TERMINAL IND RES INST CO LTD

An electromagnetic water heating and magnetic therapy health care mattress

ActiveCN103156440BEasy to useReduce energy consumptionStuffed mattressesSpring mattressesHuman bodyHigh frequency power

The invention discloses an electromagnetic water-heating magnet therapy healthcare mattress, belongs to the field of furniture for bedrooms, and particularly relates to an electromagnetic water-heating magnet therapy healthcare mattress. The electromagnetic water-heating magnet therapy healthcare mattress comprises a water cushion layer, and is characterized in that a labyrinth-shaped vertical separation layer is arranged in the water cushion layer, and a space interval in the water cushion layer is separated into labyrinth-shaped water channels which are mutually communicated by the vertical separation layer; the vertical separation layer is made from a double-layer heat-resistant and waterproof material, and more than three induction heating metal plates are arranged in the middle interlayer of the vertical separation layer; and a spiral high-frequency induction heating coil is arranged below the water cushion layer, and connected with a high-frequency power supply. The electromagnetic water-heating magnet therapy healthcare mattress is capable of uniformly heating, soft, comfortable and not easy to sway, so that the softness characteristic of the water cushion layer can be adequately exerted, and sleeping posture can be effectively improved by virtue of a memory sponge cushion layer, thus acting a good bearing effect on each physiological curved part of human body, and contributing to keeping healthy body contour and bone support; and magnetic sheets can be used for applying a positive magnetic field on the acupuncture points of human body, thus acting a good healthcare effect.

Owner:SHENZHEN ZHONGSHEN AIDE BEDDING TECH CO LTD

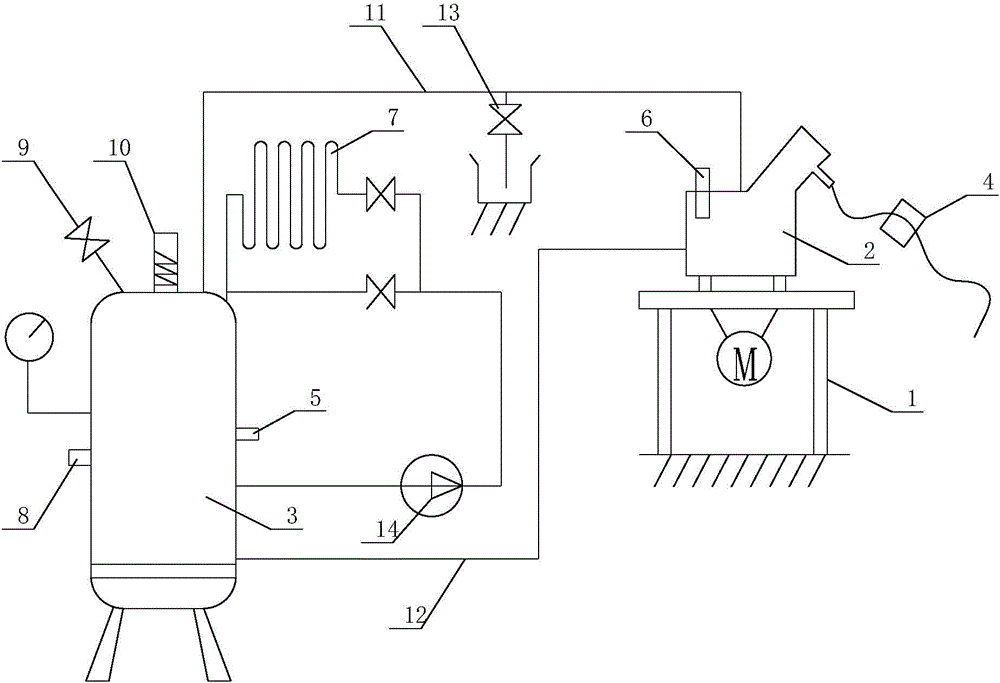

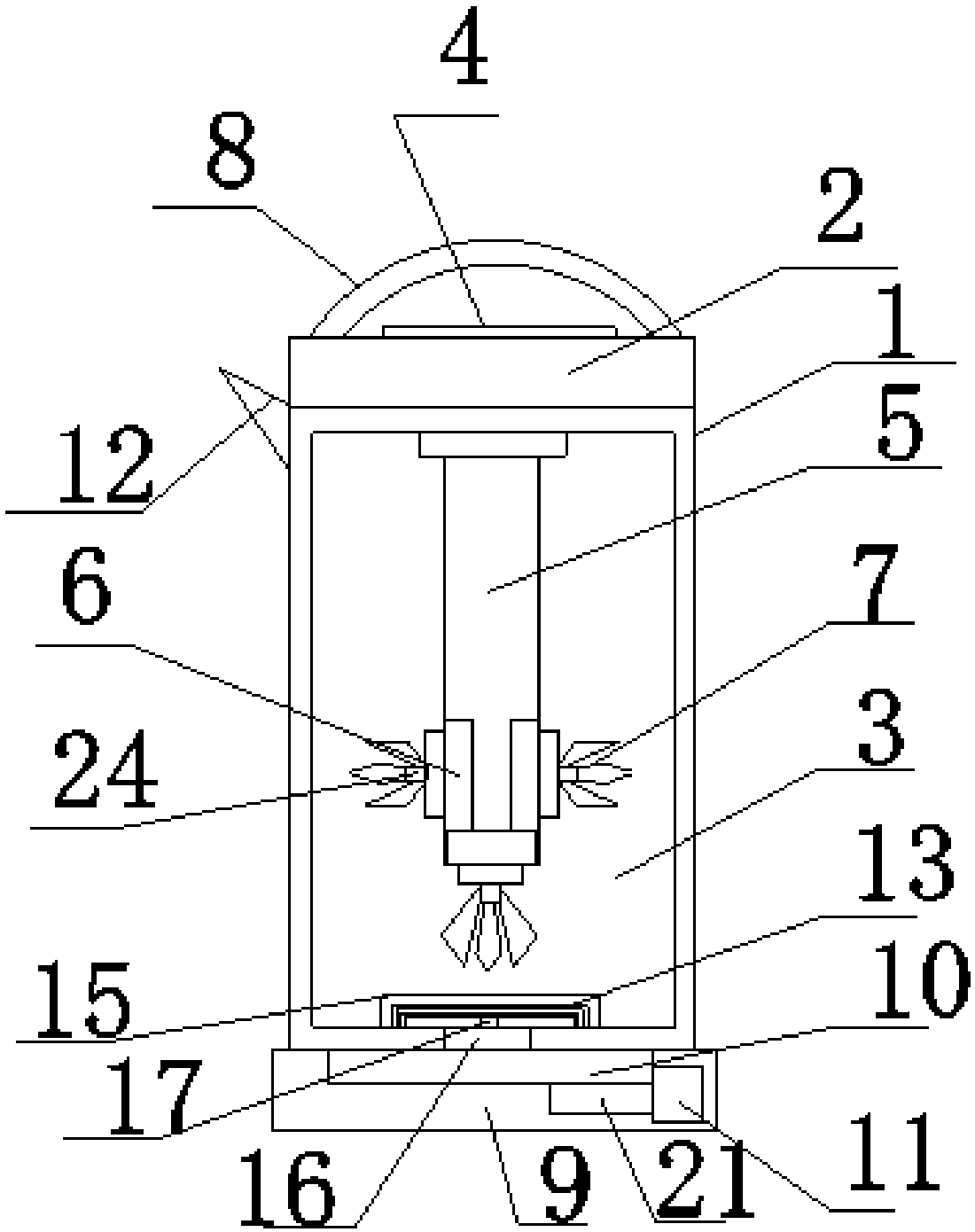

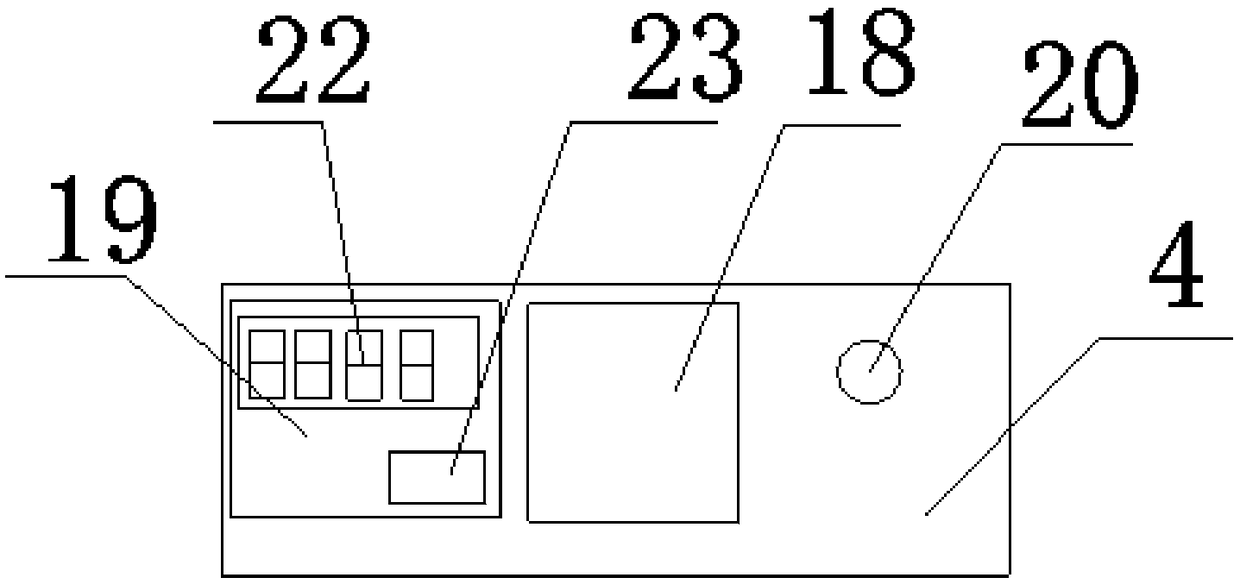

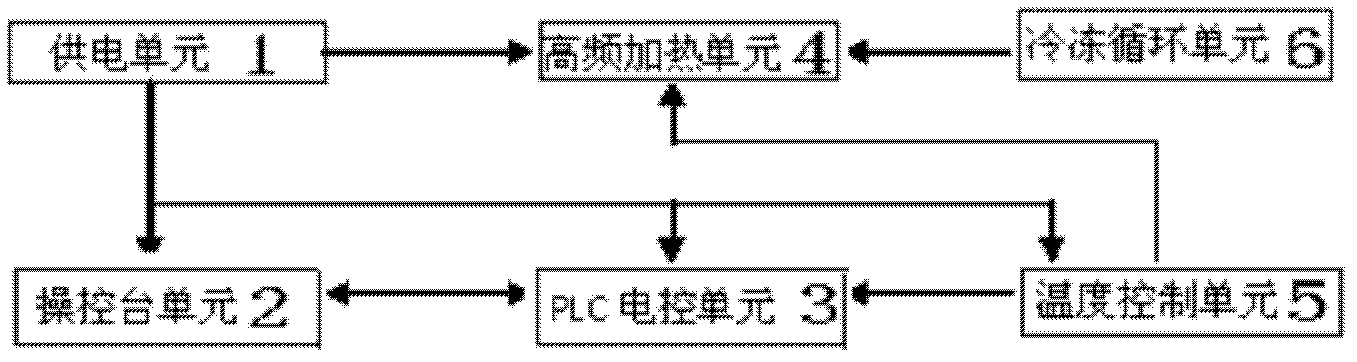

Control system of high-frequency whole body hyperthermia

InactiveCN103157190AFast heatingUniform heating rateElectrotherapyMagnetotherapyMass storageWhole body

A control system of high-frequency whole body hyperthermia comprises a power supply unit which is respectively connected with a power port of a command control consol unit, a power port of a programmable logic controller (PLC) electronic control unit, a power port of a high-frequency heating unit, and a power port of a temperature control unit. An input / output port of the command control consol unit is connected with an input / output port of the PLC electronic control unit. A first output port of the temperature control unit is connected with an input port of the PLC electronic control unit. A second output port of the temperature control unit is connected with a first input port of the high-frequency heating unit. An output port of a refrigeration cycle unit is connected with a second input port of the high-frequency heating unit. All automatic operation control is achieved by a PLC and an intelligent instrument, control is accurate, the capacity of resisting disturbance is strong, rich management functions and mass storage are realized, operation is simple and easy, the rate of safe temperature increase is high, and the entire control system works stably and reliably.

Owner:西安真核医疗科技有限公司

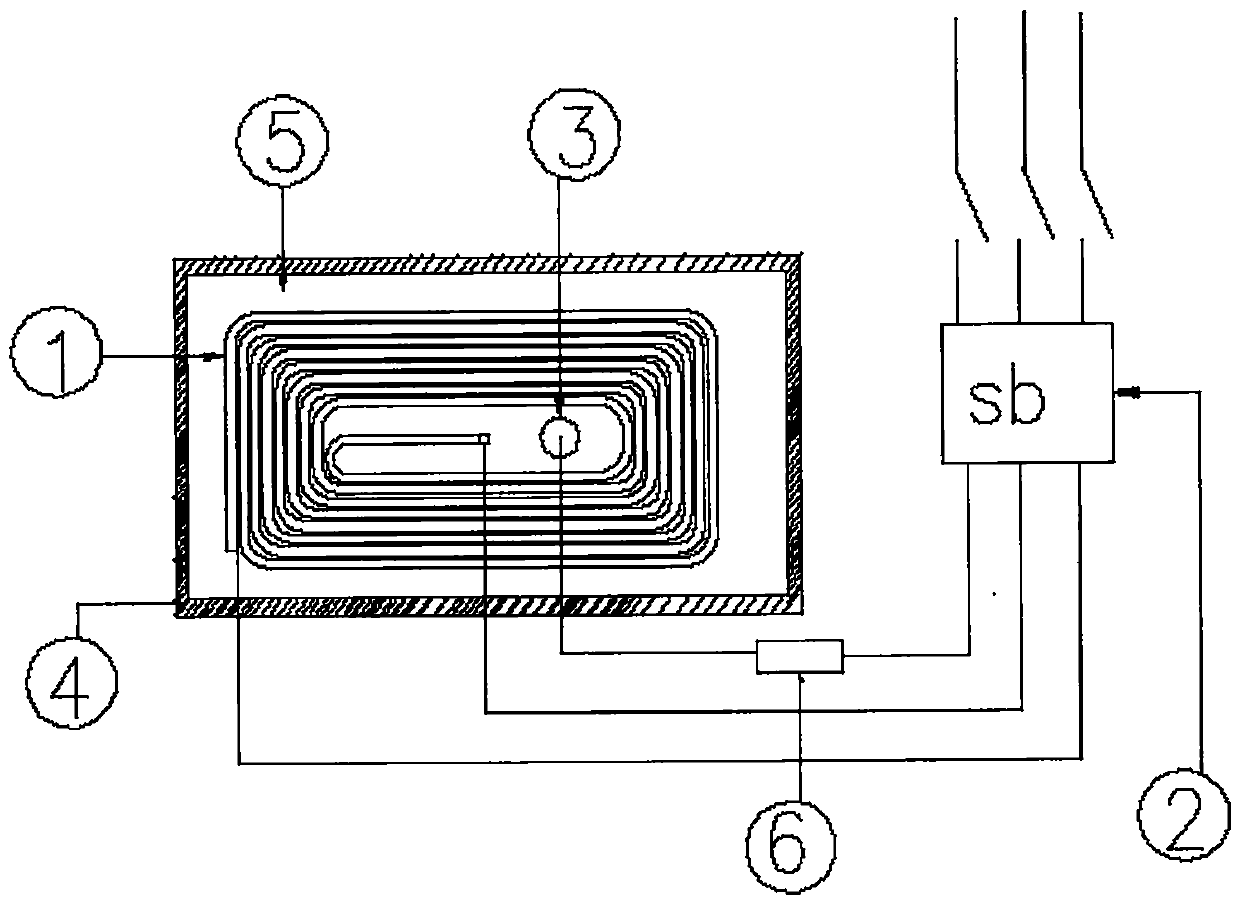

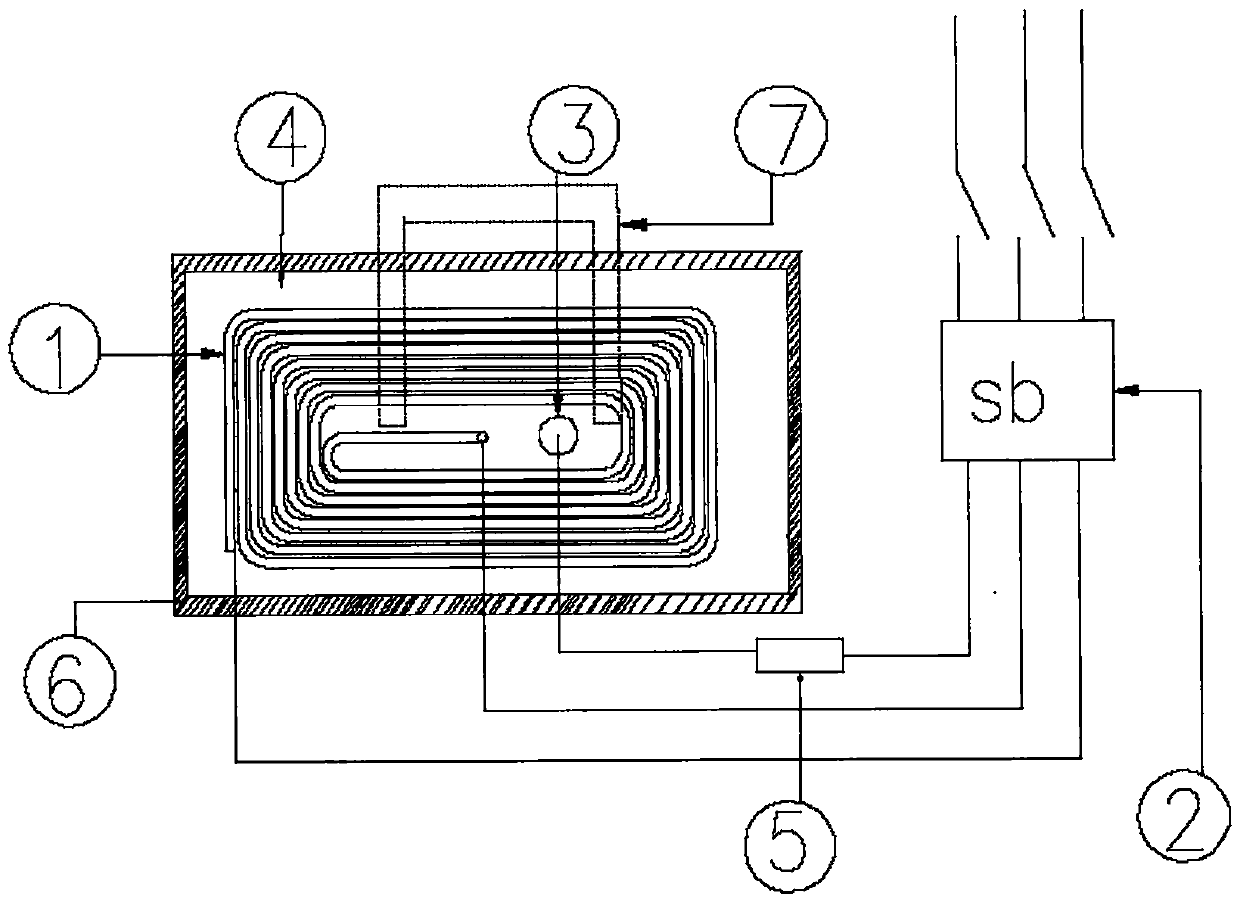

Heating device used for pipe orifice preheating

A heating device used for pipe orifice preheating is mainly used for preheating a pipe orifice before pipeline welding construction, and mainly comprises an induction coil, a sb frequency conversion power source, a temperature sensor, a thermal insulation material, a flexible shell and a temperature control device. After being mounted on the thermal insulation material, the induction coil is encapsulated in the flexible shell, then after circumferential wrapping is carried out along a pipeline, the sb frequency conversion power source is turned on, and after intermediate frequency electricity is output into the induction coil through the sb frequency conversion power source via power frequency electricity, vortexes are formed in a pipeline body to achieve heating. The temperature control device controls output of the sb frequency conversion power source according to the set temperature required by pipe orifice preheating and the real-time temperature measured by the temperature sensor. The thermal insulation material achieves the function of thermal insulation on the induction coil. The heating device has the advantages of being reasonable in structure, safe, reliable, convenient to use and free of disturbance of outside temperature.

Owner:BEIJING ZHONGKUN JIADA TECH

Manufacturing method of far-infrared heating plate containing single-layer and multi-layer graphene materials

InactiveCN112266655AFast heatingUniform heating rateChemical industryInksLight energyPhysical chemistry

The invention relates to the technical field of heating plates, particularly to a manufacturing method of a far-infrared heating plate containing single-layer and multi-layer graphene materials. The far-infrared heating plate comprises a heating film, single-layer graphene, multi-layer graphene, silver-plated nickel powder, electronic paste glass powder, polyurethane resin, a silane coupling agent, isopropanol and a non-metal plate, wherein the heating film is composed of the following components in percentage by mass: 10% of single-layer graphene, 15% of multi-layer graphene, 15% of silver-plated nickel powder, 35% of electronic paste glass powder, 20% of polyurethane resin, 2% of silane coupling agent and 3% of isopropanol. According to the manufacturing method of the far-infrared heating plate containing the single-layer graphene material and the multi-layer graphene material, electric energy is directly converted into heat energy by adopting a non-metal carbon material, generationof light energy and mechanical energy is refused, the electricity and heat conversion efficiency is improved, the generated heat mainly depends on radiation transmission, and the electricity and heatradiation conversion efficiency is effectively enhanced; and the far-infrared non-metal heating plate is a planar heating body and is high and uniform in heating speed.

Owner:贵友天创(集团)有限公司

Handheld heating device for stripping corrosion-resistant layer of oil-gas pipeline

InactiveCN110239006ANo pollution in the processFast heatingTubular articlesTemperature controlElectricity

The invention provides a handheld heating device for stripping a corrosion-resistant layer of an oil-gas pipeline. The device is mainly used for stripping the corrosion-resistant layer from the surface of the pipeline. The device mainly comprises an induction heating coil, an sb variable-frequency power supply, a temperature measurement probe, a flexible shell, a temperature control device, a heat insulation material and an operation handle. The induction heating coil is installed on the heat insulation material and then is connected with the sb variable-frequency power supply after being arranged in the flexible shell in an embedded mode. The temperature measurement probe is connected with the temperature control device and supplies control signals to the sb variable-frequency power supply. The operation handle is installed on the surface of the flexible shell. The power frequency electricity outputs the intermediate frequency electricity to the induction heating coil through the sb variable-frequency power supply to form a vortex on the surface of the pipeline, so that the corrosion-resistant layer with the softened surface is stripped after rapid heating treatment is achieved. The temperature control device controls the output of the sb variable-frequency power supply. The heat insulation material plays a role in heat insulating on the induction heating coil. The operation handle facilitates the movement of the heating device. The handheld heating device has the characteristics of being reasonable in structure, safe, reliable, convenient to use, free of pollution to the environment and free of external temperature interference.

Owner:BEIJING ZHONGKUN JIADA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com