Thick film heating element with high double-sided heat conduction capability

一种发热元件、高导热的技术,应用在加热元件、加热元件材料、电气元件等方向,能够解决没有提供高导热能力厚膜发热元件等问题,达到使用寿命长、提高导热效率、提高传热效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

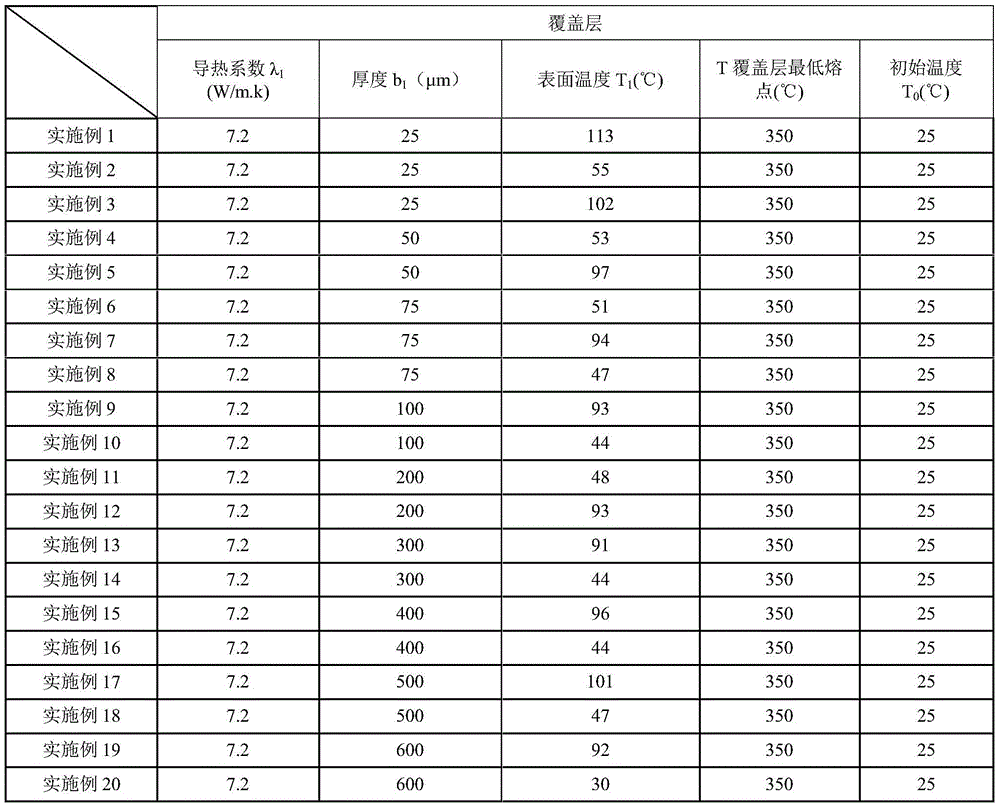

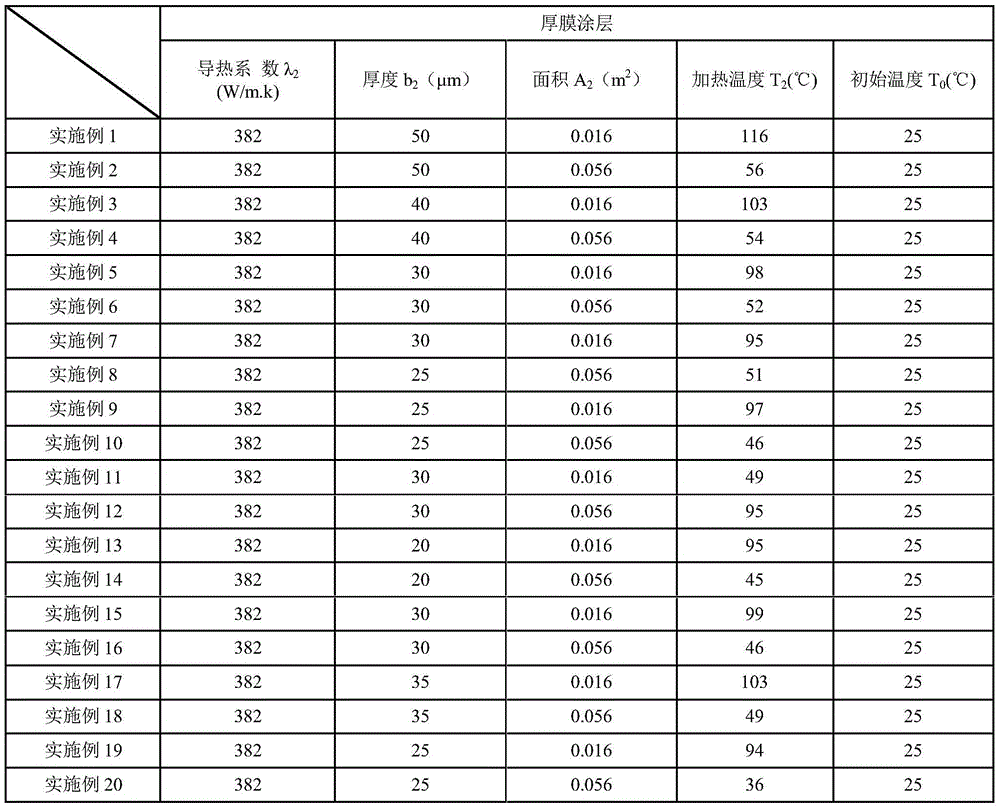

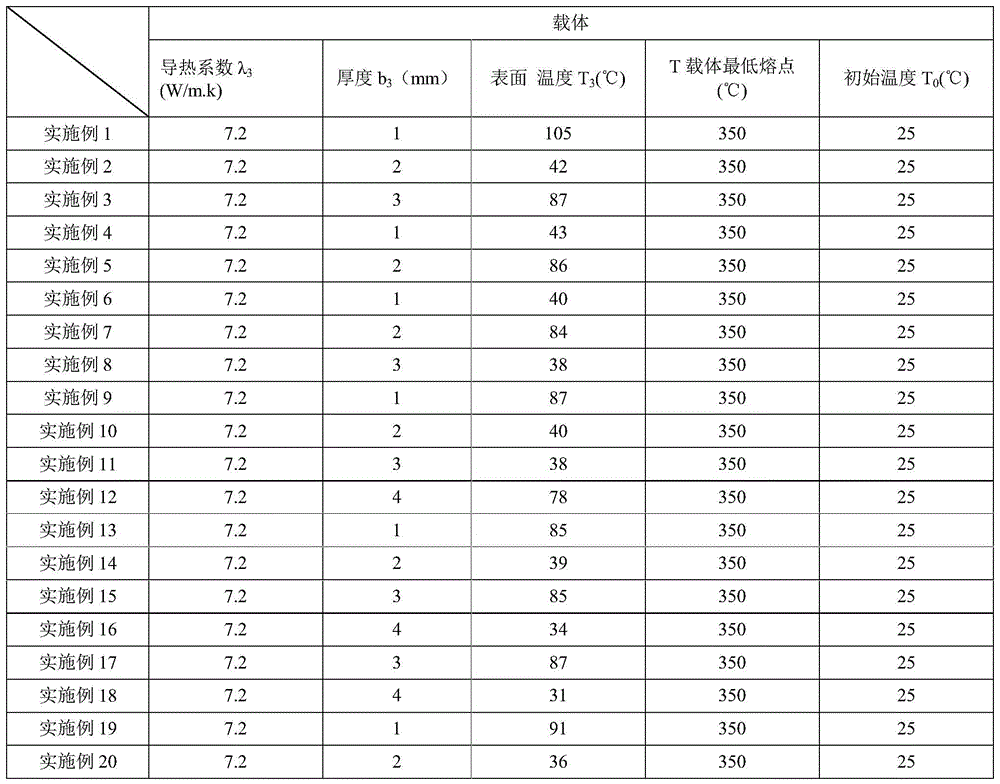

[0067] Choose the thermal conductivity as λ 2 Thick-film coatings are prepared from silver paste materials with a thermal conductivity of λ 3 The polyimide material is used to prepare the carrier, and the thermal conductivity is λ 1 The covering layer is prepared from the polyimide material, and the three layers of materials are bonded by sintering. The area of the prepared thick film coating is A 2 , the thickness of the thick film coating is b 2 ;The area of the covering layer is A 1 , thickness b 1 ;The area of the carrier is A 3 , thickness b 3 .

[0068] After turning on the switch of the external DC power supply, energize the thick film coating, and the thick film gradually heats up. After the thick film element heats up and stabilizes, measure the surface temperature of the stabilized covering layer and carrier, as well as the heating temperature of the thick film coating. , by the following formula: Calculate the heat transfer rate for the cover layer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com