Preparation method and application of large-area flexible electric heating sheet

A technology of flexible electricity and heating sheets, which is applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of insufficient softness, poor folding resistance and bending resistance, low use efficiency, etc., and achieve heat generation Fast speed, avoid alternating hot and cold, avoid the effect of hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

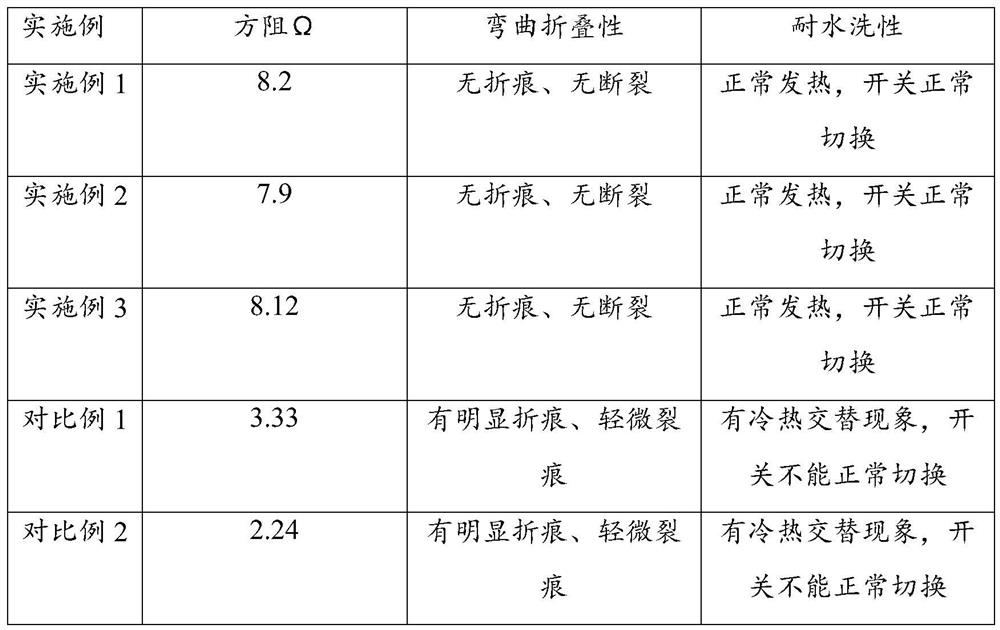

Embodiment 1

[0044] Embodiment 1 The first aspect provides a method for preparing an area flexible electric heating sheet, the steps at least include the following steps: (1) preparation of nano-carbon composite film; (2) film punching; (3) bonding of flexible conductive electrodes ; (4) thermal film bonding; (5) surface flexible substrate bonding.

[0045]The preparation of the nano-carbon composite film (in parts by weight): (1) take 70 parts of nano-carbon powder, a mixture of multi-walled carbon nanotubes and graphene and 30 parts of polyurethane resin, and melt and blend them uniformly through a high-speed mixer. The mixing temperature is 180°C; (2) After mixing evenly, the composite material is cast, calendered, drawn and shaped to obtain a uniform composite film; (3) Print conductive silver paste on the surface of the composite film to prepare a conductive silver paste layer, bake You get it.

[0046] The square resistance of the conductive silver paste is 8 milliohms; the thicknes...

Embodiment 2

[0068] The specific implementation of this embodiment is the same as that of Embodiment 1, except that the mass ratio of nano-carbon powder, multi-walled carbon nanotubes and graphene is 3:5:2.

Embodiment 3

[0070] The specific implementation of this embodiment is the same as that of Embodiment 1, except that the fineness of the nano-carbon powder is 120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com