An electrothermal treatment device for aluminum cut pellets and its implementation method

A processing device and shot cutting technology, applied in the direction of ohmic resistance heating parts, heating element shape, etc., can solve the problems of blind penetration, unfavorable use and processing, and difficult processing, etc., to achieve easy maintenance and use, improve heating efficiency, and uniform electric heat treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] In order to better demonstrate the implementation process of the aluminum cut shot electric heat treatment device, this embodiment now proposes an implementation method of the aluminum cut shot electric heat treatment device, including the following steps:

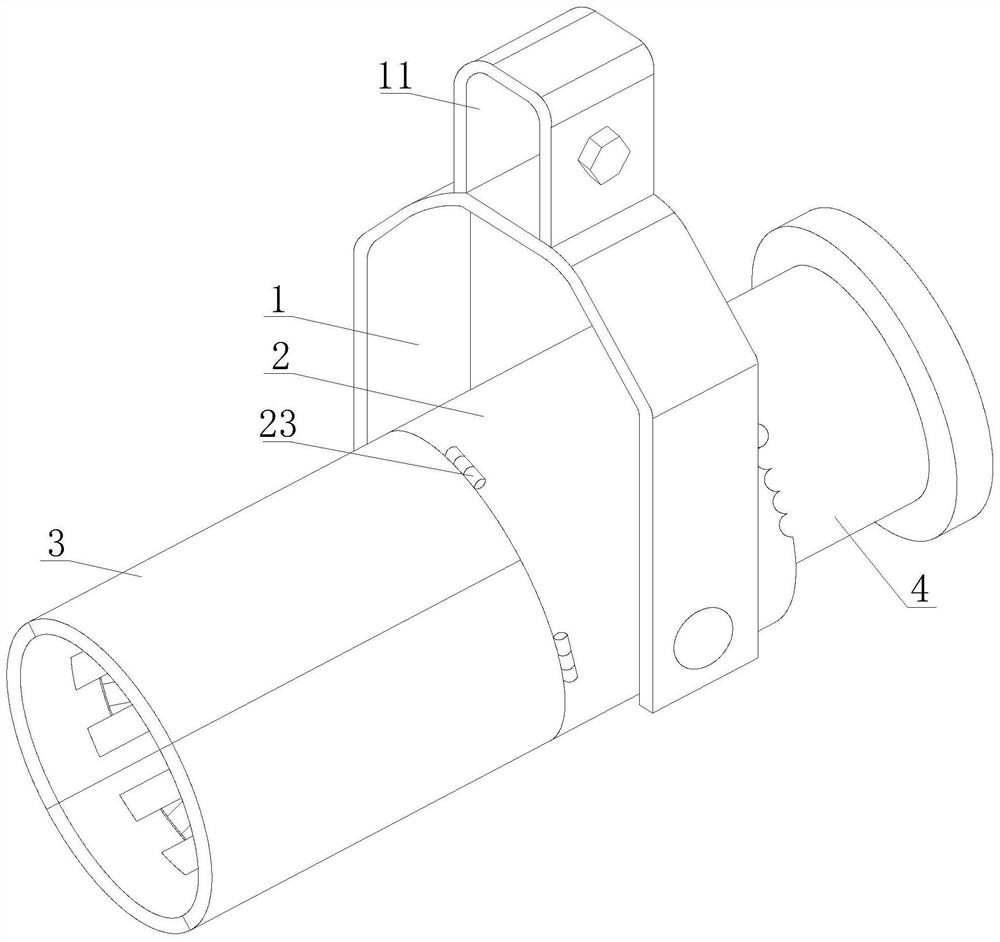

[0039] Step 1: Install and fix the mounting frame 1 on the feed port of the aluminum shot cutting device through the mounting ear 11, fix the heating cylinder 4 towards the aluminum cutting shot cutting device, install the positioning cylinder 2 through bolts, and the positioning cylinder 2 can be turned over to clean the inside dust and debris;

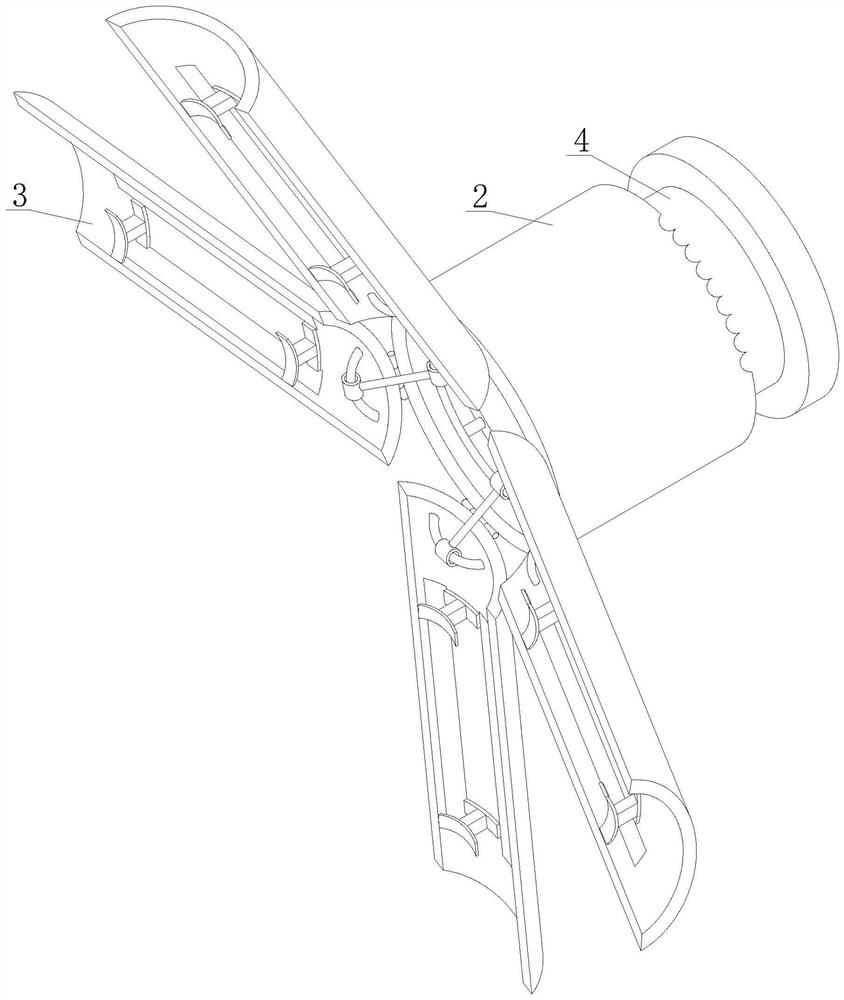

[0040] Step 2: Press the limit column 412, the support spring 411 shrinks, the limit column 412 shrinks into the spring groove 41, pushes the fixed heating cylinder 4 into the positioning cylinder 2 by a small amount, and the space between the limit column 412 and the positioning cylinder 2 Contact and rotate the limit block 46;

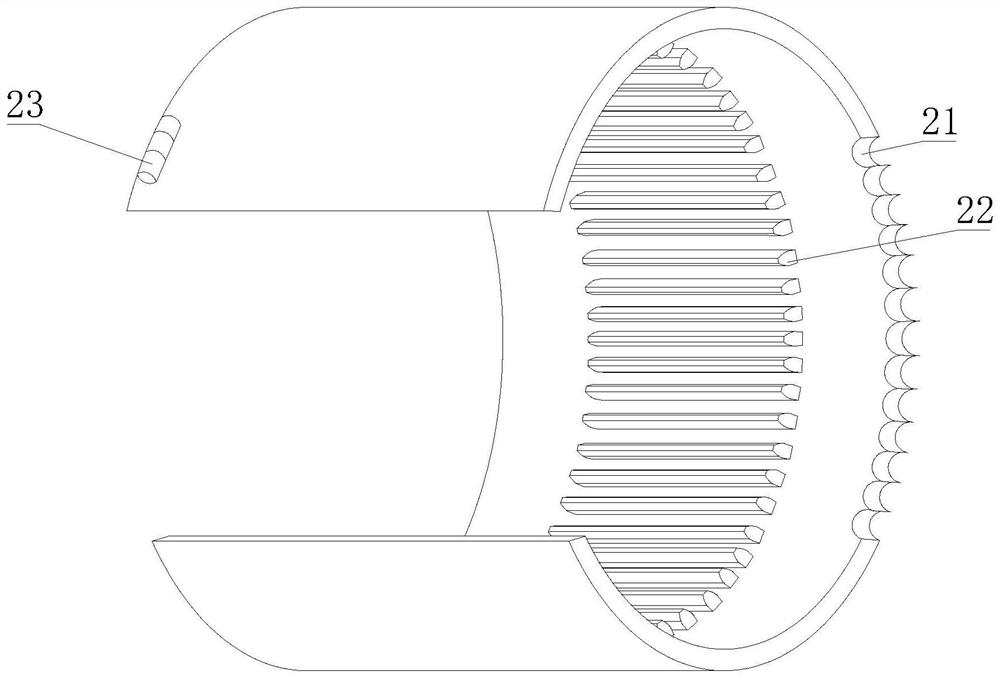

[0041] Step 3: The limit tooth block 22 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com